Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Mastering the Art of Soldering Techniques in Aircraft Maintenance

Category : | Sub Category : Posted on 2023-10-30 21:24:53

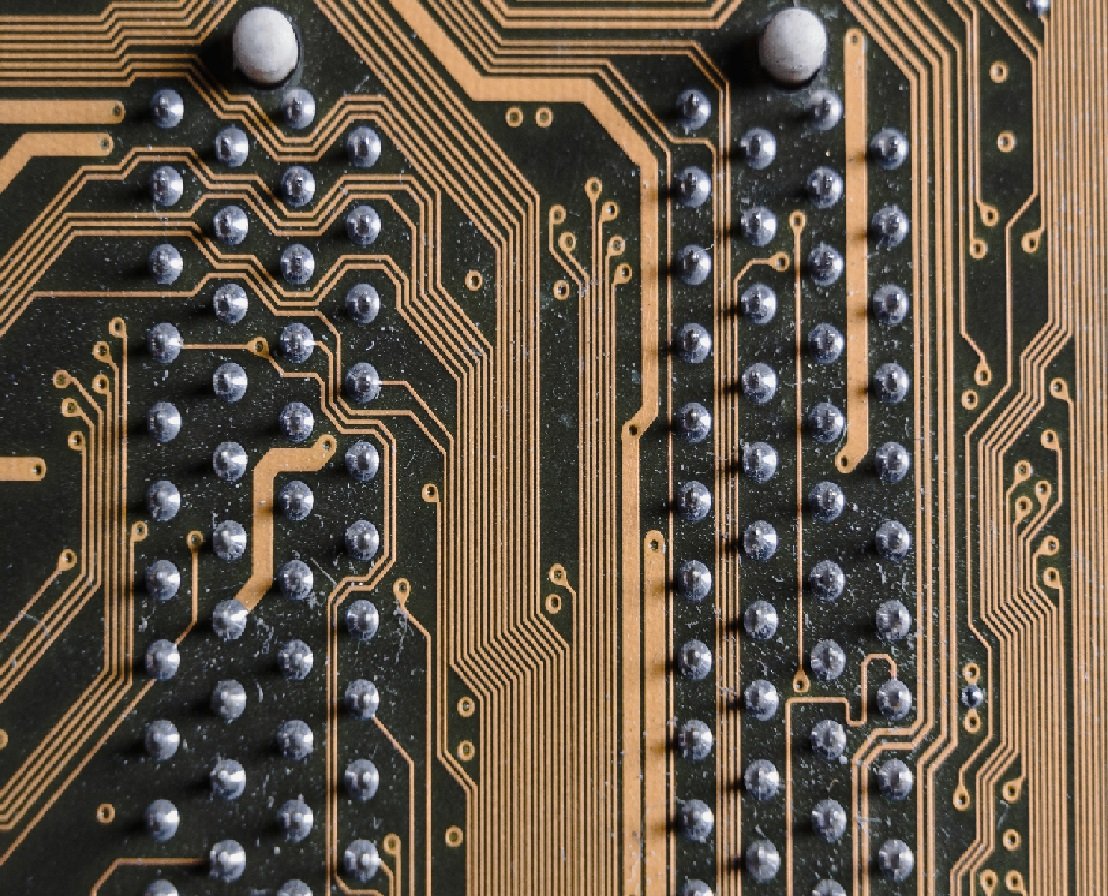

Introduction: Soldering techniques play a vital role in the maintenance and repair of aircraft. From delicate electrical connections to critical structural components, soldering ensures seamless performance and reliability. In this blog post, we will delve into the world of aircraft soldering techniques and explore the best practices for achieving exceptional results. 1. The Importance of Soldering in Aircraft Maintenance: Soldering plays a crucial role in the aviation industry, as it is used to connect wires, components, and circuit boards in various aircraft systems. Proper soldering ensures secure and durable connections, prevents electrical failures, and enhances overall safety. 2. Understanding the Different Soldering Techniques: There are several soldering techniques commonly used in aircraft maintenance, each catering to specific requirements. These techniques include: a. Through-Hole Soldering: This technique is used to solder components with leads passing through holes in the circuit board. It involves heating the components' leads and applying solder to create strong electrical connections. b. Surface Mount Soldering: Surface mount devices (SMDs) have become increasingly prevalent in modern aircraft. This technique involves soldering components directly onto the surface of the circuit board using a reflow oven or a soldering iron with a fine tip. c. Wire Soldering: Aircraft wiring requires meticulous soldering to ensure reliable electrical connections. From avionics to lighting systems, soldering wires is essential for maintaining proper functionality. 3. The Equipment Needed for Aircraft Soldering: To achieve professional results in aircraft soldering, specific tools and equipment are essential. These include: a. Soldering Iron: A temperature-controlled soldering iron is crucial for precision soldering in aircraft maintenance. Selecting the appropriate tip ensures proper heat distribution and control. b. Flux: Flux helps remove oxidation and prevents the formation of solder bridges. It enhances the solder flow and promotes stronger connections. c. Solder Wire: High-quality solder wire with a suitable composition is critical. Lead-free solder is typically used in aerospace applications to comply with environmental regulations. d. Soldering Stand: A sturdy soldering stand provides stability and prevents accidental damage caused by the hot soldering iron. 4. Best Practices for Achieving Quality Solder Joints: To achieve reliable and consistent solder joints in aircraft maintenance, these best practices should be followed: a. Cleanliness is Crucial: Proper cleaning of the surface to be soldered is imperative. Remove any dirt, dust, or oxidation using isopropyl alcohol or specialized cleaning agents. b. Temperature Control: Maintain the correct soldering iron temperature depending on the material being soldered. Excessive heat can damage components, while insufficient heat can result in a weak or unreliable joint. c. Use the Right Amount of Solder: Applying an adequate amount of solder ensures a strong joint without creating excessive solder bridges or "cold joints." d. Inspect and Test: Inspect the solder joints for a smooth, shiny surface with good wetting. Conduct electrical tests to verify the integrity of the connections. Conclusion: Mastering soldering techniques in aircraft maintenance is essential for maintaining the safety and reliability of modern aircraft. By understanding the different soldering techniques, using appropriate equipment, and following best practices, aviation professionals can ensure reliable electrical connections and structural integrity. Remember, precision and attention to detail are the keys to achieving optimal solder joints in the ever-evolving world of aircraft technology. click the following link for more information: http://www.jetiify.com Want a more profound insight? Consult http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :