Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Advancements in Surface Mount Technology Electronics for Aircrafts

Category : | Sub Category : Posted on 2023-10-30 21:24:53

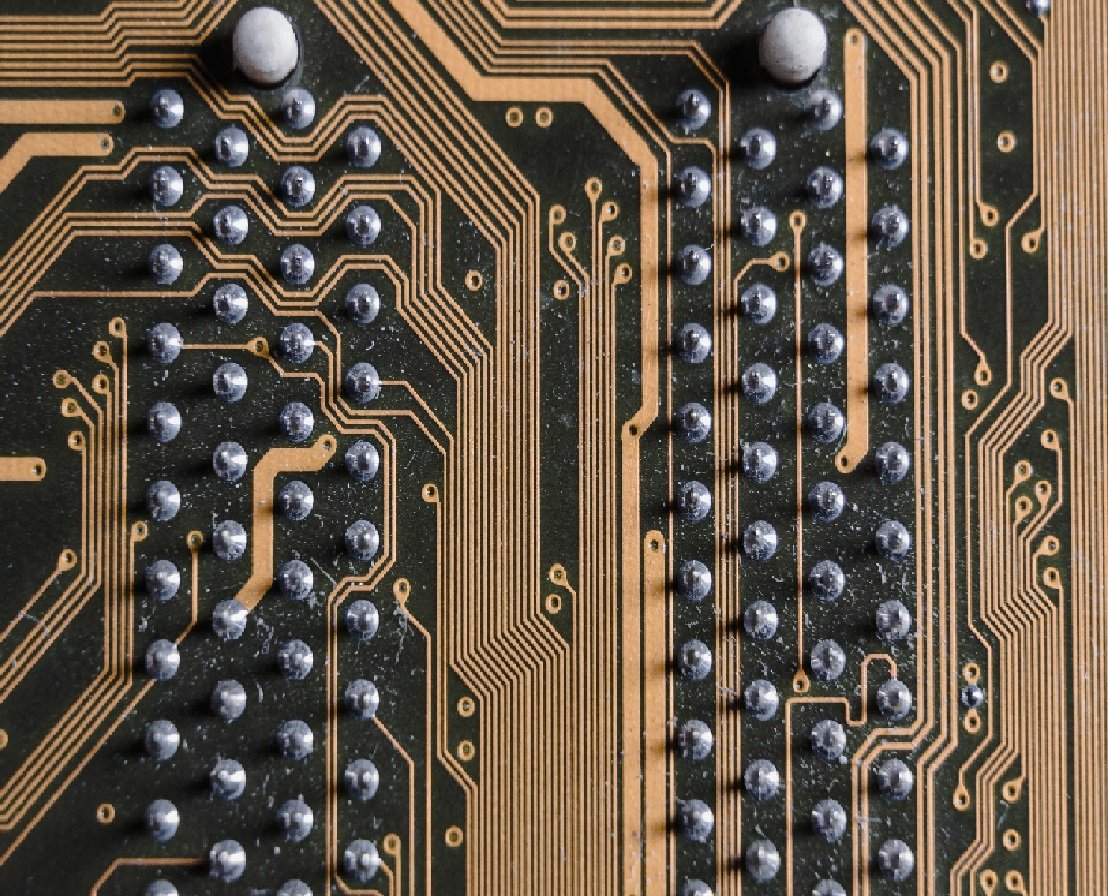

Introduction: As technology continues to evolve, so does the aviation industry. Aircrafts these days are more advanced than ever, with cutting-edge electronics playing a crucial role in their operation. Among these advancements is the use of surface mount technology (SMT) electronics. In this blog post, we will explore what SMT electronics are, their advantages, and how they are revolutionizing aircraft design and performance. What is Surface Mount Technology Electronics? Surface mount technology involves the assembly of electronic components directly onto the surface of printed circuit boards (PCBs) without the need for traditional through-hole mounting. Instead of soldering the leads of components to the PCB, SMT components are soldered to the board surface, resulting in a more compact, lightweight, and efficient design. Advantages of SMT Electronics in Aircrafts: 1. Miniaturization: SMT components are significantly smaller than their through-hole counterparts. This miniaturization allows for more complex circuitry to be packed into smaller spaces, saving valuable real estate inside the aircraft. It also contributes to weight reduction, which improves fuel efficiency. 2. Enhanced Performance: The compact and precise nature of SMT electronics results in improved performance and reliability. High-frequency signals can be transmitted more efficiently, minimizing signal loss and interference. This leads to enhanced communication capabilities, better navigation systems, and overall safer and more efficient aircraft operations. 3. Cost-Effective: SMT electronics are more cost-effective compared to through-hole technology, primarily due to automated assembly processes. These processes can accurately place and solder multiple components simultaneously, reducing labor costs and increasing production efficiency. 4. Increased Production Speed: By using SMT electronics, manufacturers can speed up the assembly process. Automated machines can accurately place and solder components, resulting in faster production times. This allows for quicker aircraft deliveries, reducing lead times and meeting market demands more efficiently. Applications of SMT Electronics in Aircrafts: 1. Avionics Systems: Avionics systems, including flight control systems, navigation systems, and communication systems, rely heavily on SMT electronics. The compact and reliable nature of SMT components ensures accurate data processing, efficient signal transmission, and optimal system performance. 2. Cabin Electronics: From in-flight entertainment systems to passenger control units, SMT electronics are widely used in the cabin. These components ensure seamless connectivity, advanced audiovisual experiences, and passenger comfort, all while conserving valuable space within the aircraft. 3. Sensors and Instrumentation: SMT electronics are also extensively used in sensors and instrumentation systems within the aircraft. These systems include airspeed indicators, altimeters, temperature sensors, and more. By accurately measuring and transmitting data, SMT electronics play a crucial role in maintaining the aircraft's safety and performance. Conclusion: Surface mount technology electronics have revolutionized the aviation industry, enabling aircrafts to become smarter, more efficient, and safer. The compact size, enhanced performance, cost-effectiveness, and increased production speed of SMT components make them a preferred choice in aircraft design. As technology continues to advance, we can expect further improvements in SMT electronics, paving the way for even more innovative solutions in the aviation field. Looking for more information? Check out http://www.jetiify.com for more http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :