Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Mastering Soldering Techniques in Autonomous Robotics

Category : | Sub Category : Posted on 2023-10-30 21:24:53

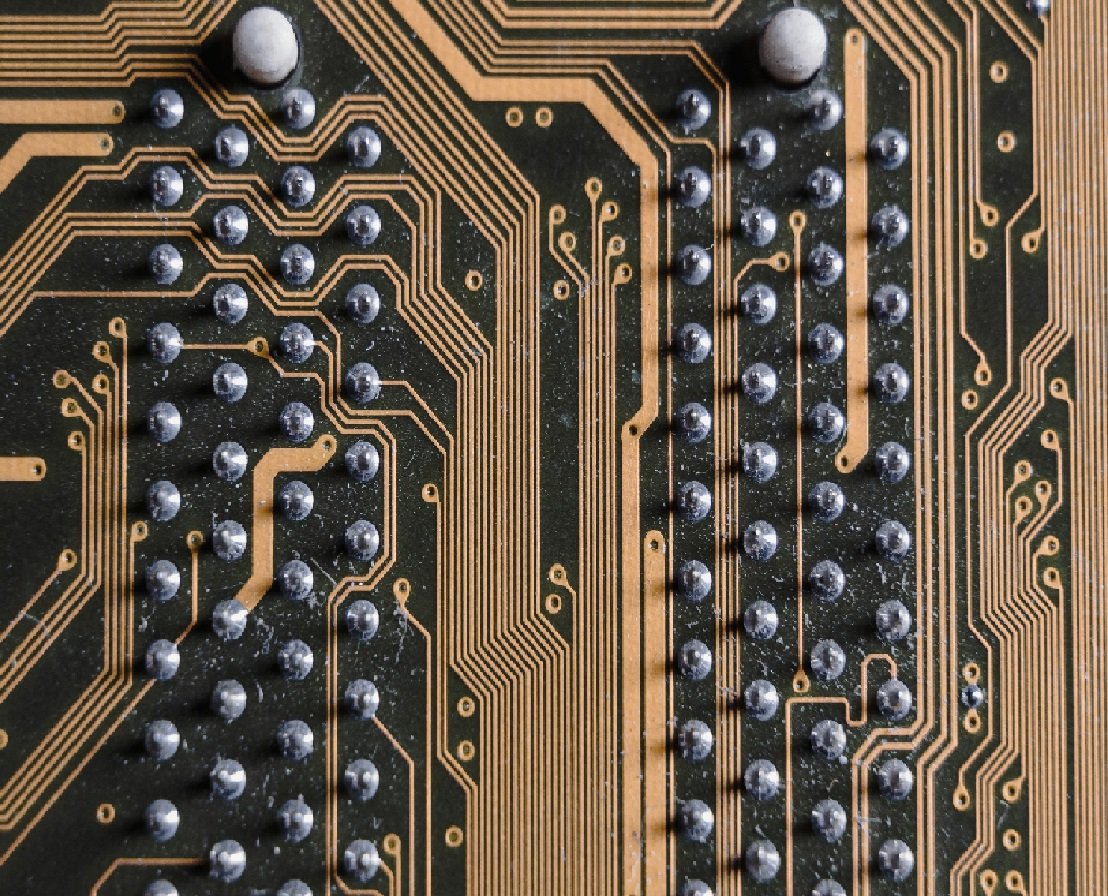

Introduction: As the field of autonomous robotics continues to advance, the ability to effectively solder components has become an invaluable skill for robotics engineers, hobbyists, and enthusiasts alike. Soldering is the process of joining electrical components by melting a metal alloy (solder) to create a strong and durable bond. In this blog post, we will explore some essential soldering techniques specifically tailored to the field of autonomous robotics. 1. Choosing the Right Soldering Equipment: To get started with soldering, it is crucial to have the right equipment. A temperature-controlled soldering station with variable settings is ideal for precise control over the soldering process. Additionally, invest in a quality soldering iron with interchangeable tips, ensuring you have a variety of options to suit different component sizes and complexities. 2. Practice Proper Heating Techniques: One of the keys to successful soldering is ensuring correct heating techniques. When soldering delicate components in autonomous robotics, it is crucial to use a fine tip on your soldering iron and apply just enough heat to melt the solder without overheating or damaging the component. Remember to always heat the component, not the solder itself, to ensure a strong and reliable joint. 3. Proper Component Preparation: Before soldering, it is essential to prepare the components adequately. Start by cleaning the surfaces of the components using isopropyl alcohol to remove any dirt, debris, or oxidation. Use a soldering flux to further enhance the solder's ability to bond with the component, ensuring a strong and durable connection. 4. Use the Right Solder: Choosing the right solder is vital for soldering success in autonomous robotics. Lead-free solder is recommended for robotics applications to comply with environmental regulations. The most common type of solder used in the field is a eutectic solder with a melting point around 183C. Selecting the appropriate diameter of solder wire is also crucial depending on the component size and complexity. 5. Mastering Soldering Techniques: a) Dab and Drag: This technique involves heating the component and applying the solder wire to the connection point. Once the solder melts, quickly move the soldering iron away while maintaining contact between the solder and the component, ensuring proper flow and distribution. b) Through-Hole Soldering: Autonomous robotics often involve through-hole components where leads pass through PCB holes. In this technique, heat the pad and lead simultaneously, applying the solder on the opposite side of the iron to allow it to flow through the hole and bond the component to the board. c) Surface Mount Soldering: This technique is commonly used in modern robotics. Apply a small amount of solder paste to the pads, carefully position the component, and use a reflow oven or hot air gun to melt the solder, creating a strong bond between the component and the PCB surface. Conclusion: Ensuring strong and reliable connections in autonomous robotics is essential for their optimal performance and longevity. By mastering the art of soldering and following the techniques outlined in this blog post, you will be better equipped to handle the intricate electrical connections found in robotics projects. Remember, practice makes perfect, so keep honing your skills to become an expert in soldering techniques for autonomous robotics. To get a different viewpoint, consider: http://www.pxrobotics.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :