Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Evolution of Cameras in Electronics Manufacturing: A Technological Revolution

Category : | Sub Category : Posted on 2023-10-30 21:24:53

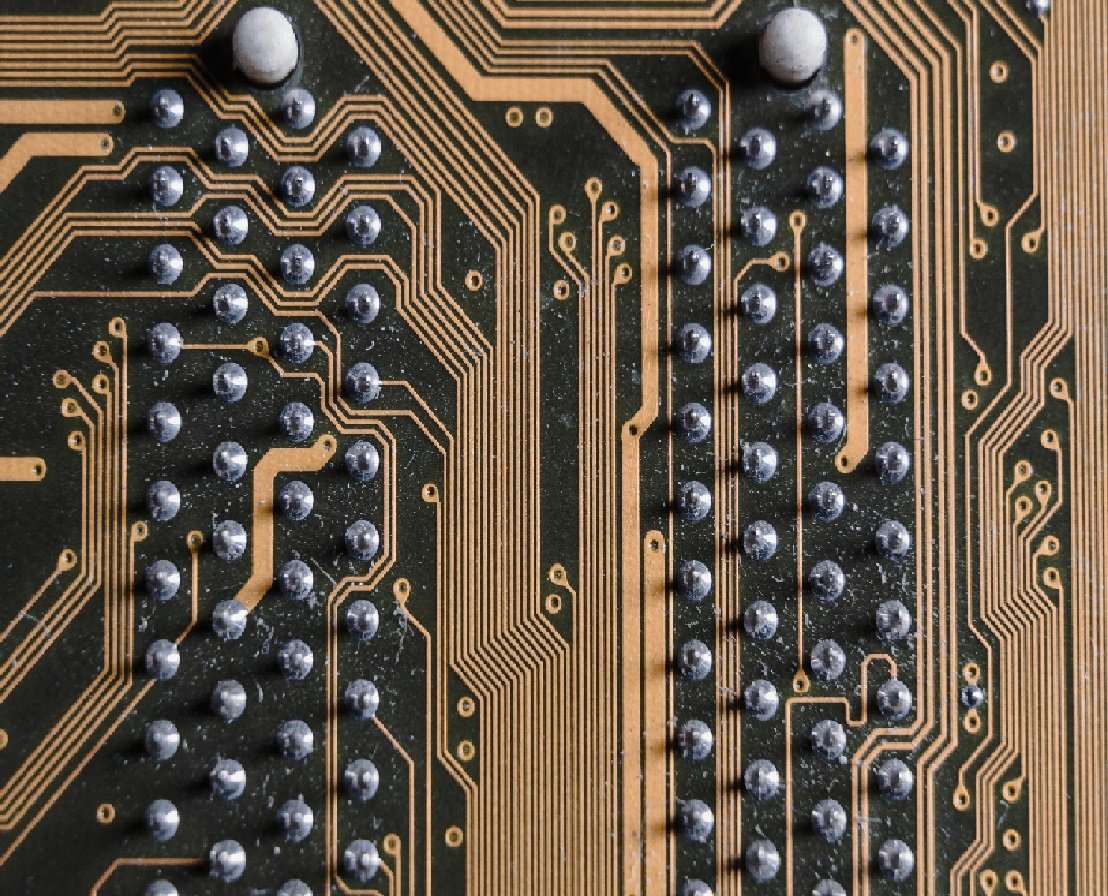

Introduction: In the world of electronics manufacturing, advancements in technology have played a pivotal role in improving processes and enhancing product quality. One such area that has witnessed significant progress is the development of cameras used in manufacturing facilities. In this blog post, we will explore the evolution of cameras and their impact on electronics manufacturing. 1. Early Days: Analogue Cameras In the early days of electronics manufacturing, analogue cameras were predominantly used for quality inspections and monitoring production processes. These cameras provided a basic level of visual inspection, capturing images that could be later reviewed by operators. While these cameras played an essential role, they had limitations in terms of image quality and accuracy. 2. Transition to Digital Cameras The advent of digital technology brought about a remarkable shift in the camera landscape. Digital cameras quickly replaced analogue cameras in electronics manufacturing facilities. These cameras offered numerous advantages, including higher image resolution, instant image previews, and the ability to store digital images for future reference. This transition to digital cameras significantly improved the efficiency and accuracy of quality inspections. 3. Integration with AI and Machine Learning As technology continues to advance, cameras in electronics manufacturing are now being integrated with artificial intelligence (AI) and machine learning capabilities. This combination allows cameras to not only capture images but also analyze the data in real-time. AI-powered cameras can detect defects, measure product dimensions, and perform complex algorithms to identify and classify potential issues. These intelligent cameras enable faster and more accurate quality checks, reducing human error and increasing overall productivity. 4. Robotic Vision Systems Another significant development in the field of cameras in electronics manufacturing is the integration of cameras with robotic systems. Robotic vision systems are used to guide robotic arms, inspect products, and identify defects automatically. These systems can perform complex tasks such as component placement verification, solder joint inspection, and surface analysis with precision and speed. The integration of cameras with robotics has revolutionized the automation of manufacturing processes, resulting in increased efficiency and reduced costs. 5. 3D Imaging and Depth Perception The latest frontier in camera technology for electronics manufacturing lies in 3D imaging and depth perception. 3D cameras capture depth information, allowing for more accurate analysis and measurement of complex components. By combining depth information with AI algorithms, these cameras enable precise inspection and measurement, even in challenging situations. Manufacturers can now detect defects that were previously difficult to identify, ensuring product quality is maintained at the highest level. Conclusion: The evolution of cameras in electronics manufacturing has transformed the industry, improving quality control, speeding up production, and reducing costs. From the early analogue cameras to the integration of AI and machine learning, cameras have become an indispensable tool in modern manufacturing processes. With further advancements in technology, we can expect even more sophisticated camera systems that will continue to drive innovation in the electronics manufacturing industry. Discover new insights by reading http://www.fmount.net also visit the following website http://www.keralachessyoutubers.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :