Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Exploring Cameras and Surface Mount Technology in Electronics

Category : | Sub Category : Posted on 2023-10-30 21:24:53

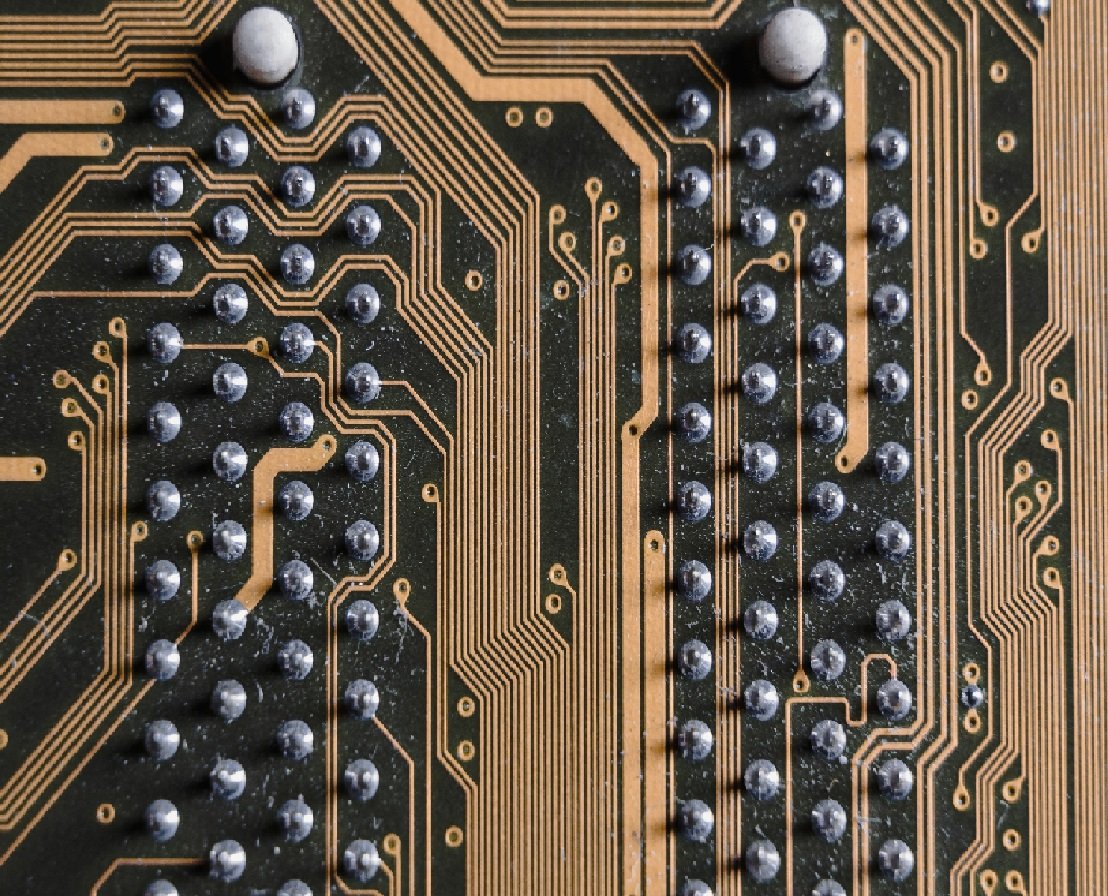

Introduction: In today's fast-paced world, cameras have become an integral part of our lives. Whether it's capturing precious moments, streaming live videos, or monitoring our surroundings, cameras play a crucial role. But have you ever wondered how these remarkable devices are manufactured? Enter surface mount technology (SMT) in electronics. In this blog post, we will dive into the world of cameras and explore the importance of surface mount technology in their production. What is Surface Mount Technology (SMT)? Surface mount technology, commonly known as SMT, is a method used to construct electronic circuits by placing electronic components directly onto the surface of printed circuit boards (PCBs). In contrast to through-hole technology, where components have leads that are inserted into holes in the PCB, SMT components are mounted directly on the board's surface using specialized equipment. The Role of SMT in Camera Manufacturing: When it comes to cameras, surface mount technology plays a vital role in ensuring sleek, compact designs, improved functionality, and reduced manufacturing costs. By utilizing SMT, manufacturers can densely populate PCBs with small-sized components, thus making cameras smaller and more lightweight. This allows for increased portability, making cameras more user-friendly and adaptable to various scenarios. Advantages of SMT in Camera Production: 1. Size and Weight Reduction: SMT enables the placement of components on both sides of the PCB, making the camera thin and compact. This advancement allows for sleek designs and comfortable handling, ensuring cameras are easier to carry around for photographers or videographers. 2. Enhanced Performance and Functionality: SMT components are known for their small size and high-density packaging. This enables manufacturers to incorporate advanced features, such as high-resolution sensors, multiple lenses, and image stabilization systems, all while maintaining the camera's sleek form factor. 3. Increased Efficiency and Cost-effectiveness: SMT technology automates the assembly process, reducing labor costs and improving production efficiency. The precise placement of components also improves the overall reliability and durability of cameras, thereby minimizing the need for repairs or replacements. 4. Speed and Precision: SMT machines are capable of placing components on PCBs at a rapid pace, significantly reducing production time. The accuracy and precision of SMT equipment also ensure that components are correctly aligned and soldered, resulting in a reliable and robust camera design. Future Trends and Innovations in Camera Production: As technology continues to advance, we can expect even more exciting developments in camera manufacturing. Some future trends and innovations include: 1. Miniaturization: Cameras will continue to become smaller and more portable while maintaining high-resolution imaging capabilities. 2. Integration with Artificial Intelligence (AI): AI-powered features, such as facial recognition, scene detection, and image enhancement, will become increasingly common in cameras, improving the overall photography experience. 3. Advanced Image Sensors: The evolution of image sensor technology will enable cameras to capture even more detailed and lifelike images, even in challenging lighting conditions. Conclusion: Surface mount technology has revolutionized the way cameras are manufactured, allowing for smaller, more feature-rich devices that meet the demands of modern-day users. As advancements in technology continue, we can expect cameras to become even more portable, intelligent, and capable of capturing stunning visuals. So next time you pick up your camera to capture a beautiful moment, remember the critical role that surface mount technology plays in bringing these devices to life. Seeking in-depth analysis? The following is a must-read. http://www.fmount.net Looking for more information? Check out http://www.keralachessyoutubers.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :