Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Exploring Through-Hole Technology: Revolutionizing Electronics and Cameras

Category : | Sub Category : Posted on 2023-10-30 21:24:53

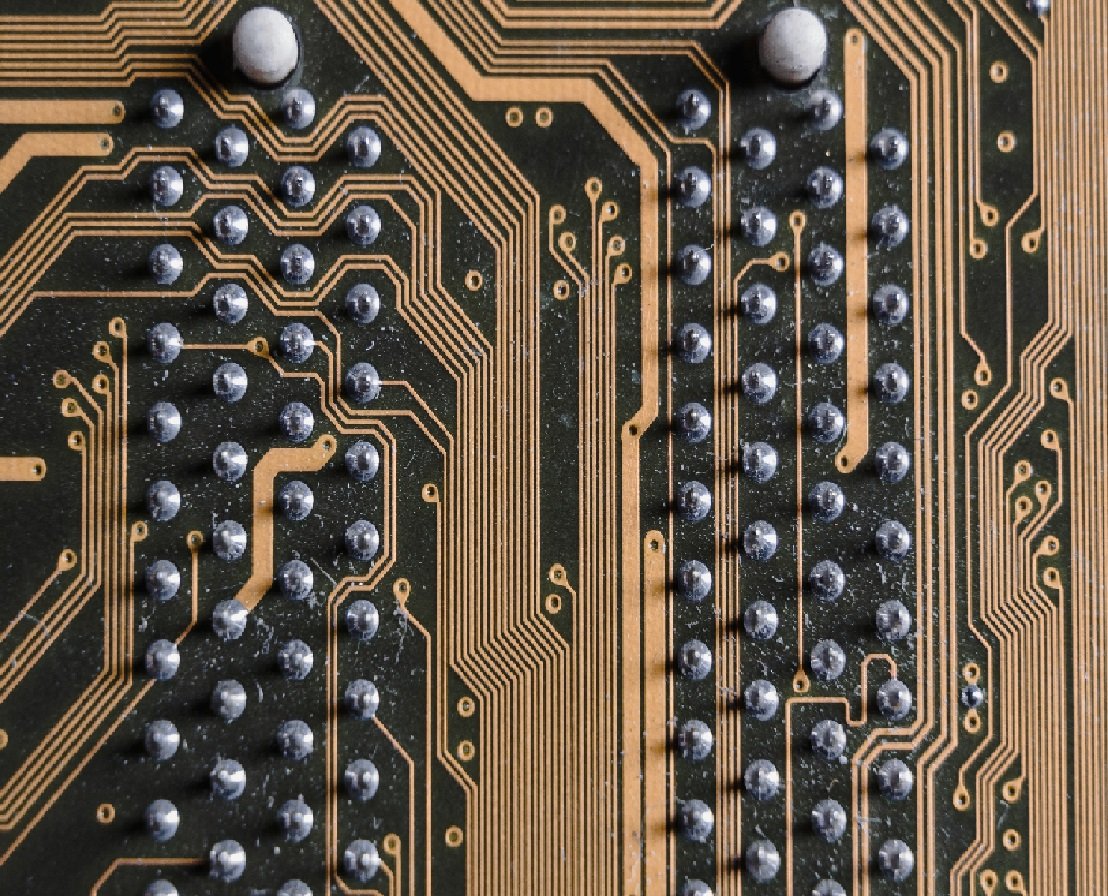

Introduction: In the world of electronics and imaging, through-hole technology has played a vital role in the development of advanced cameras. This time-tested technique has enabled the production of durable and high-performing devices, making it an essential component in the photography industry. In this blog post, we will delve into the intricacies of through-hole technology and its significance in the evolution of cameras. Understanding Through-Hole Technology: Through-hole technology is a conventional method of constructing electronic circuits by inserting components through pre-drilled holes on a PCB (Printed Circuit Board). This method allows for sturdy connections and ensures the durability of the electronic device. Unlike surface-mount technology (SMT), where components are mounted directly onto the PCB, through-hole technology offers better stability and protection against vibrations and mechanical stress. The Role of Through-Hole Technology in Camera Manufacturing: Through-hole technology has made immense contributions to the advancement of camera technology. The technique is commonly employed in manufacturing camera modules, lens housings, and image sensors, among other critical camera components. Due to their small size and intricate design, cameras demand the use of through-hole technology to ensure reliable connections and robust performance in various conditions. Benefits of Through-Hole Technology in Camera Production: 1. Durability: Through-hole components are mechanically more secure than their surface-mounted counterparts. This advantage is particularly crucial for cameras that may face rigorous usage in diverse environments, such as extreme temperatures or high humidity. 2. Enhanced Precision: The through-hole mounting process allows for precise alignment of components, ensuring optimal performance. Cameras require utmost accuracy in their construction to provide sharp images and accurate focus, making through-hole technology an ideal choice. 3. Ease of Repair: In case of component failure or damage, through-hole technology facilitates straightforward repair or replacement, as the components can be desoldered and replaced individually. This advantage promotes cost-effectiveness and extends the lifespan of cameras. 4. Reliability: The reliability offered by through-hole technology is highly valuable for cameras used in critical applications such as surveillance, medical imaging, or industrial inspection. The robust connections provided by through-hole components reduce the risk of failure or malfunction. Future Prospects of Through-Hole Technology in Cameras: Although surface-mount technology has gained popularity due to its smaller footprint and compatibility with miniaturized designs, through-hole technology continues to be a vital part of camera manufacturing. The demand for rugged and high-performance cameras in various industries ensures that through-hole technology will remain relevant in the foreseeable future. Furthermore, advancements in through-hole technology, such as automated insertion machines and lead-free components, have made the manufacturing process more efficient and environmentally friendly. These enhancements will continue to drive the adoption of through-hole technology in camera production. Conclusion: Through-hole technology has proven to be an essential aspect of camera manufacturing. Its durability, precision, ease of repair, and reliability make it an optimal choice for building top-quality cameras capable of capturing breathtaking images in all environments. While surface-mount technology may dominate in certain applications, through-hole technology will continue to be an indispensable technique in the evolution of cameras, ensuring their longevity and performance. Explore expert opinions in http://www.fmount.net Discover new insights by reading http://www.keralachessyoutubers.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :