Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Evolution of PCB Design Software in the UK Automotive Industry

Category : | Sub Category : Posted on 2023-10-30 21:24:53

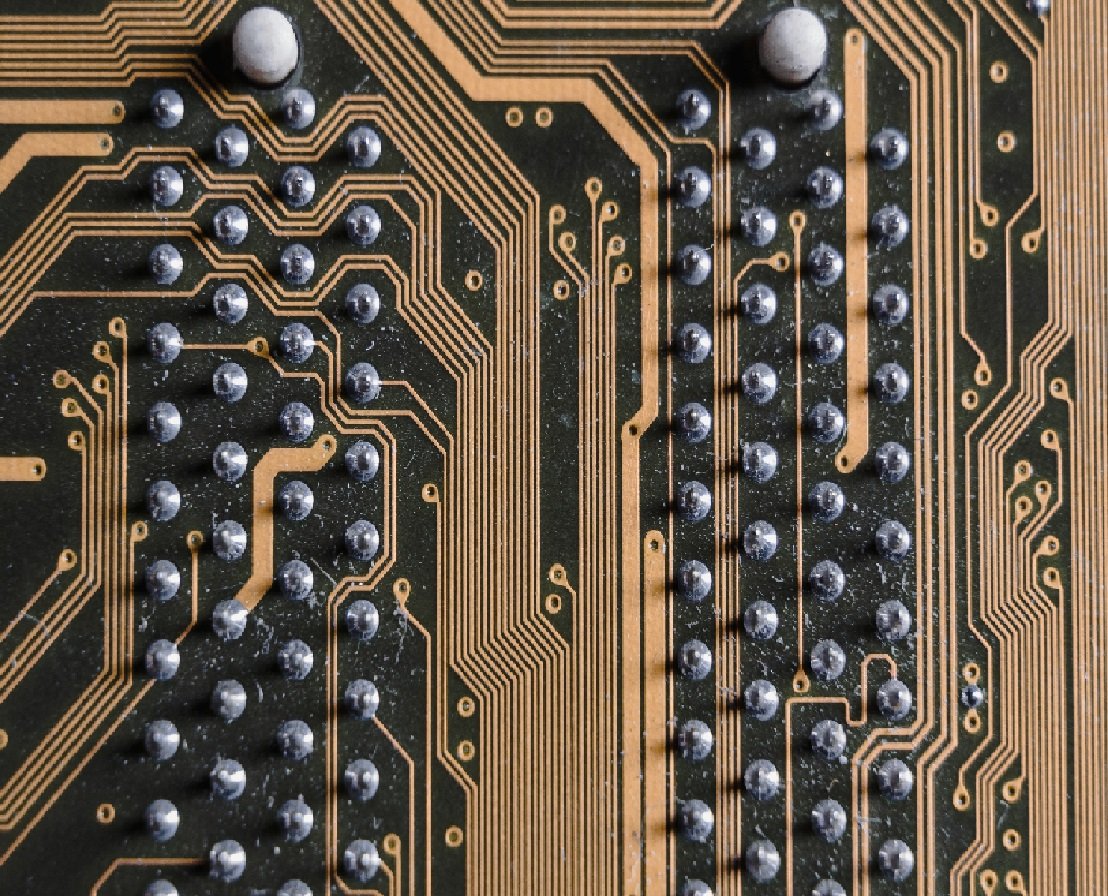

Introduction: In the rapidly advancing automotive industry, efficient and accurate design processes are crucial for staying competitive. One area that has witnessed significant advancements is the design of Printed Circuit Boards (PCBs) used in cars. This blog post will explore the evolution of PCB design software in the UK automotive industry and how it has revolutionized the way vehicles are manufactured. The Importance of PCB Design in Cars: PCBs play a crucial role in modern vehicles, acting as the nervous system that connects various electronic components. From engine management systems to advanced driver-assistance features, PCBs ensure seamless communication between different parts of the car. Efficient PCB design is vital for reducing manufacturing costs, improving reliability, and optimizing performance. Traditional Design Methods: Before the advent of modern software, PCB designs were primarily created using manual methods. Designers relied on pen and paper to sketch circuit diagrams, which were then converted into physical boards using complex etching processes. While this method had its merits, it was time-consuming, prone to errors, and limited in terms of complexity. The Emergence of PCB Design Software: The introduction of PCB design software revolutionized the automotive industry, providing designers with powerful tools and features to streamline the design process. CAD (Computer-Aided Design) software, specifically tailored for PCBs, allowed for the creation of complex and intricate circuit layouts with advanced functionality. Advancements in the UK Automotive Industry: The UK automotive industry has been at the forefront of adopting advanced PCB design software. A growing number of companies are investing heavily in software solutions that enable faster design iterations, greater collaboration among teams, and improved overall product quality. One notable trend in the UK automotive industry is the integration of simulation and analysis tools within PCB design software. Designers can now simulate the behavior of the PCB in various operating conditions, assess its thermal performance, and optimize it for signal integrity. This integration reduces the need for physical prototypes, resulting in significant time and cost savings. Furthermore, the advent of cloud-based PCB design software has further enhanced collaboration and productivity. Design teams can now work simultaneously on a project, making real-time edits and updates. This seamless integration provides a significant advantage in an industry that thrives on innovation and time-to-market. Looking Forward: As technology continues to evolve, the future of PCB design software in the UK automotive industry looks promising. Advancements in machine learning and artificial intelligence are likely to further improve design automation, enabling designers to create more efficient and compact PCB layouts. Moreover, the integration of Internet of Things (IoT) technologies in vehicles will demand even more advanced PCB design software. Automotive PCBs will need to handle large amounts of data, accommodate wireless connectivity, and support real-time communication with the surrounding environment. Conclusion: The evolution of PCB design software has significantly transformed the automotive industry in the UK. From manual drafting to advanced computer-aided tools, the design process has become faster, more efficient, and highly collaborative. With the rise of new technologies, PCB design software will continue to play a crucial role in driving innovation and enhancing the performance of vehicles on UK roads. Want a deeper understanding? http://www.mywowcar.com Seeking answers? You might find them in http://www.cardirs.com Here is the following website to check: http://www.qqhbo.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :