Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Exploring the Advancements of Chinese Surface Mount Technology in Electronics Manufacturing

Category : | Sub Category : Posted on 2023-10-30 21:24:53

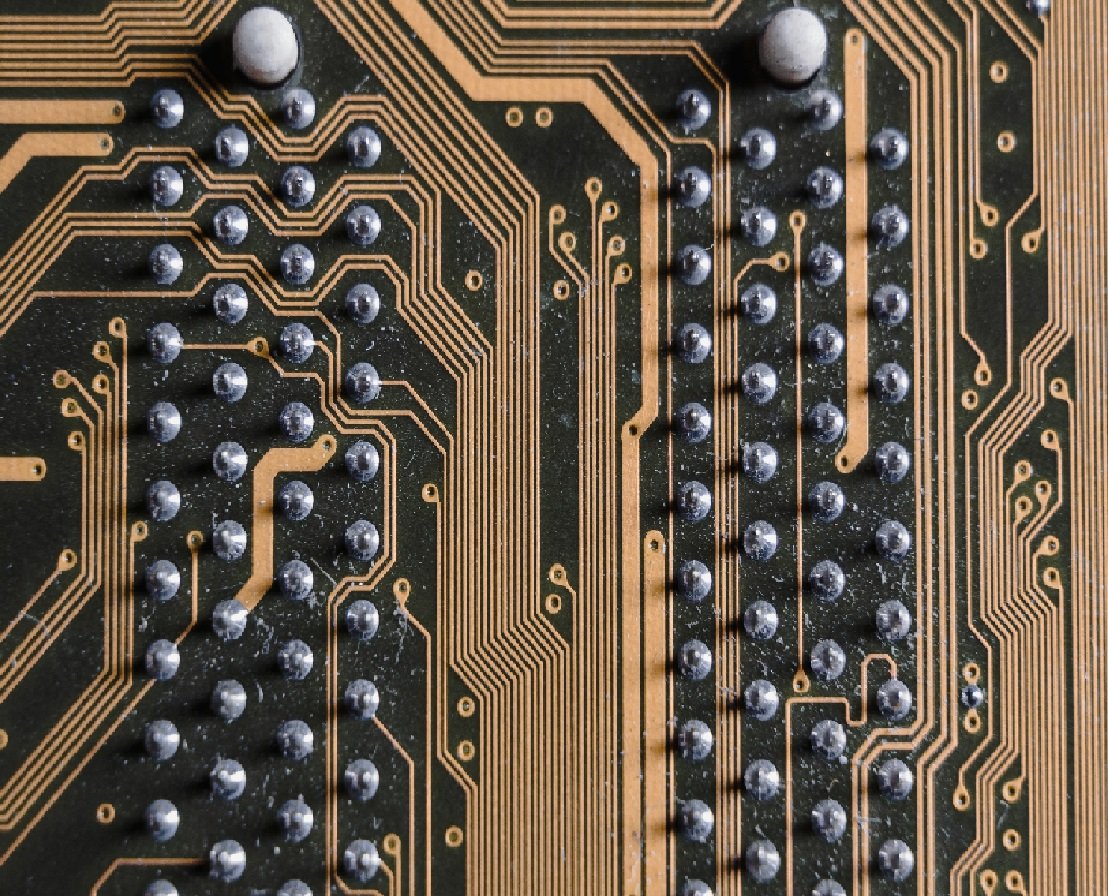

Introduction: In the fast-paced world of electronics manufacturing, surface mount technology (SMT) has revolutionized the way electronic components are mounted onto printed circuit boards (PCBs). Among the leaders in SMT innovation is China, which has emerged as a global hub for electronics manufacturing. In this blog post, we will delve into the advancements of Chinese surface mount technology in electronics and its impact on the industry. 1. The Rise of Chinese Surface Mount Technology: China's electronics industry has experienced rapid growth over the past few decades, positioning the country as a major player on the global stage. Surface mount technology has played a significant role in this growth, enabling manufacturers to achieve higher efficiency, increased productivity, and greater precision in electronic assembly. 2. Miniaturization and Component Density: One of the key advantages of SMT is its ability to accommodate smaller and more compact electronic devices. Chinese manufacturers have harnessed SMT to push the boundaries of miniaturization, resulting in smaller, lighter, and more powerful electronics. This has paved the way for advancements in mobile devices, wearables, Internet of Things (IoT) devices, and more. 3. Automation and Enhanced Productivity: Chinese manufacturers have heavily invested in automation to streamline their production process and enhance productivity. By leveraging robotics, vision systems, and advanced assembly equipment, surface mount technology allows for faster and more accurate component placement. This not only reduces manufacturing costs but also improves overall product quality. 4. Flexibility and Versatility: Chinese surface mount technology has proven to be highly versatile, catering to a wide variety of electronic applications. From consumer electronics to automotive and medical devices, SMT provides manufacturers with the flexibility to handle diverse product requirements. This adaptability has contributed to the growth of China's electronics industry, serving both domestic and international markets. 5. Quality Control and Testing: To meet the demanding quality standards of the global market, Chinese manufacturers have implemented stringent quality control measures throughout the surface mount technology process. Automated optical inspection (AOI) systems and X-ray inspection play a vital role in identifying defects, ensuring reliable and robust electronic products. 6. Research and Development: China's commitment to research and development has propelled its surface mount technology capabilities to new heights. Academic institutions, government initiatives, and collaborations with industry leaders have fostered innovation and technological advancements. This investment in R&D has allowed Chinese manufacturers to stay ahead of the curve and drive the growth of the electronics industry. Conclusion: Chinese surface mount technology has undoubtedly shaped the landscape of electronics manufacturing. Through advancements in miniaturization, automation, flexibility, and quality control, Chinese manufacturers continue to push the boundaries of what is possible in the world of electronics. As the industry evolves, China's expertise in SMT is set to bring even more innovation, creating exciting possibilities for the future of technology. References: - "The Importance and Advantages of Surface Mount Technology (SMT)" by PCB Solutions - "What is Surface Mount Technology (SMT)?" by EMSGlobalsupply - "China's electronics industry soars ahead on the global stage" by Nikkei Asia sources: http://www.soitsyou.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :