Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Role of Colors in Electronics Failure Analysis

Category : | Sub Category : Posted on 2023-10-30 21:24:53

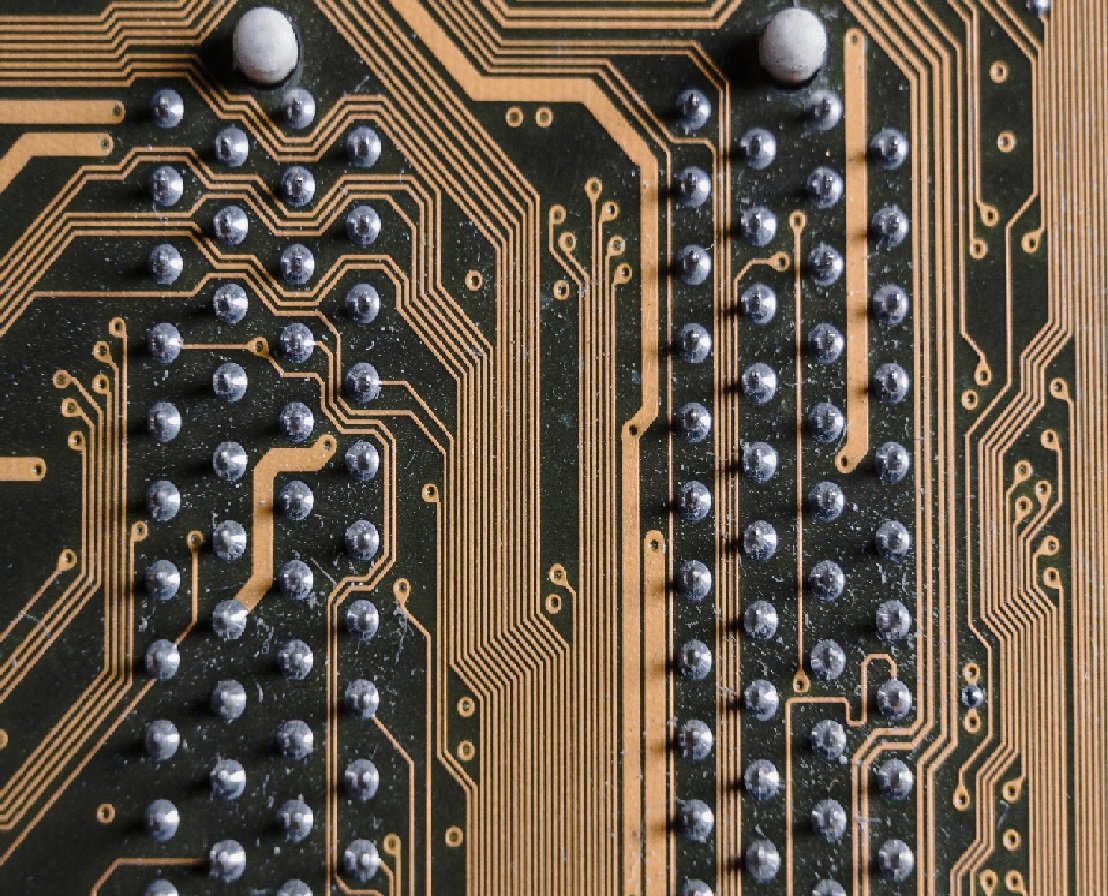

Introduction: In today's digital age, electronic devices have become an indispensable part of our lives. From smartphones to laptops, the technology we rely on every day is constantly evolving. However, even the most advanced electronic products are not immune to failures. One often overlooked yet crucial aspect of failure analysis in electronics is the role that colors play. Colors can provide valuable clues for technicians and engineers to identify the root cause of a malfunction. In this blog post, we will explore how colors aid in electronics failure analysis and the significance they hold in diagnosing and resolving issues. 1. Visual Indicators: Colors act as visual indicators that alert technicians to potential problems. For example, a change in color or intensity of an LED light can indicate a power supply issue or a faulty component. By closely observing these color changes, technicians can quickly identify where the problem lies and take appropriate actions. 2. Traces and Connectors: Colors are often used to label traces and connectors on circuit boards. These labels help technicians understand the connectivity and pathways of signals between different components. In case of a failure, identifying any color deviations or abnormalities can lead to pinpointing the source of the issue. By tracing the path and analyzing the color-coded connections, engineers can identify the faulty component or the point of failure. 3. Component Identification: The color of electronic components can also provide valuable information during failure analysis. For instance, resistors, capacitors, and other components are often color-coded to represent their values and tolerance levels. An incorrect color coding or a deviation from specifications can help in diagnosing and resolving circuitry issues. By cross-referencing colors with technical documentation or using specialized tools, technicians can quickly identify mismatches and replace faulty components. 4. Thermal Analysis: Colors can even play a role in thermal analysis of electronic devices. Heat-sensitive materials often change color when they reach certain temperatures. This can indicate overheating or inefficient heat dissipation, which can lead to the failure of sensitive components. By using thermal imaging cameras or thermal paints, engineers can identify hotspots or anomalies, aiding in the prevention of future failures. Conclusion: The use of colors in electronics failure analysis is an often overlooked but vital aspect of identifying and resolving issues. From visual indicators and color-coded connectors to component identification and thermal analysis, colors provide valuable insights for technicians and engineers. By leveraging these visual cues, professionals can diagnose failures more efficiently, ultimately improving the reliability and performance of electronic devices. For valuable insights, consult http://www.colorsshow.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :