Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Colors in PCB Design Software: Aesthetics and Functionality

Category : | Sub Category : Posted on 2023-10-30 21:24:53

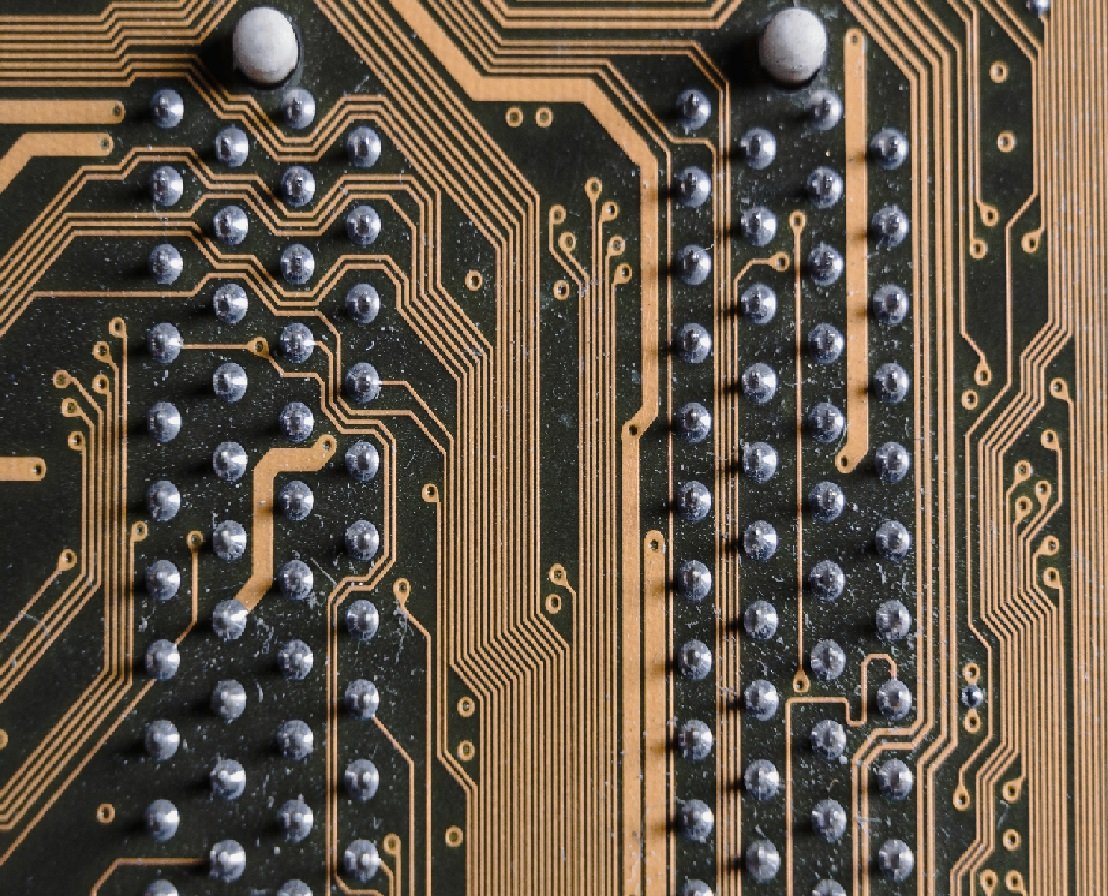

Introduction: When it comes to designing printed circuit boards (PCBs), there are many factors to consider to ensure a successful outcome. PCB design software plays a crucial role in this process, and one often overlooked aspect is the use of colors. In this article, we will explore the importance of colors in PCB design software, both from an aesthetic and functional standpoint. Aesthetics Matter: 1. Visual Clarity and Organization: Colors in PCB design software help in improving visual clarity and organization. By using different colors for different components, traces, and layers, designers can quickly identify and differentiate between various elements on the board. This enhances the overall readability and comprehension of the design, leading to fewer errors and easier modifications. 2. Branding and Customization: Colors can be utilized to reflect and reinforce a company's branding. PCB design software that allows customization of color schemes enables designers to align their PCB designs with their brand's visual identity. By incorporating company-specific colors into the design, the final product can have a professional and cohesive look, strengthening brand recognition. Functionality Matters: 1. Signal Integrity and Trace Routing: Color coding is crucial in ensuring signal integrity and trace routing accuracy. Different colors can be assigned to various signal types, such as power, ground, or data, making it easier for designers to track signal paths across the PCB. This helps minimize signal interference, crosstalk, and aids in fault analysis. Color cues can also be used to highlight high-speed signal traces that require meticulous attention during routing, preventing layout errors that might impact signal integrity. 2. Layer Differentiation: Modern PCBs often consist of multiple layers, and distinguishing between them accurately is vital. Colors can be used to visually differentiate between different layers, such as the top, bottom, signal, power, or ground planes. This enables the designer to quickly understand layer stacking, identify layer-specific components, and ensures precise layer alignment during the fabrication process. 3. Manufacturing Guidelines: During the PCB manufacturing process, different colors can be used to convey manufacturing guidelines, helping manufacturers understand design requirements efficiently. For example, using a particular color for copper pours or highlighting solder mask layers can assist manufacturers in identifying critical areas and applying the necessary techniques during production. Conclusion: Colors play a significant role in PCB design software, both in terms of aesthetics and functionality. By utilizing colors effectively, designers can create visually appealing and organized PCB designs. Additionally, color coding enhances signal integrity, aids in trace routing, and ensures proper layer differentiation, ultimately resulting in a higher quality end product. Next time you're working on a PCB design, don't underestimate the importance of colors in your design software. Consider leveraging the power of colors to enhance both the visual appeal and functionality of your project, ultimately leading to improved design efficiency and overall success. also for More in http://www.colorsshow.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :