Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Colorful World of Soldering Techniques

Category : | Sub Category : Posted on 2023-10-30 21:24:53

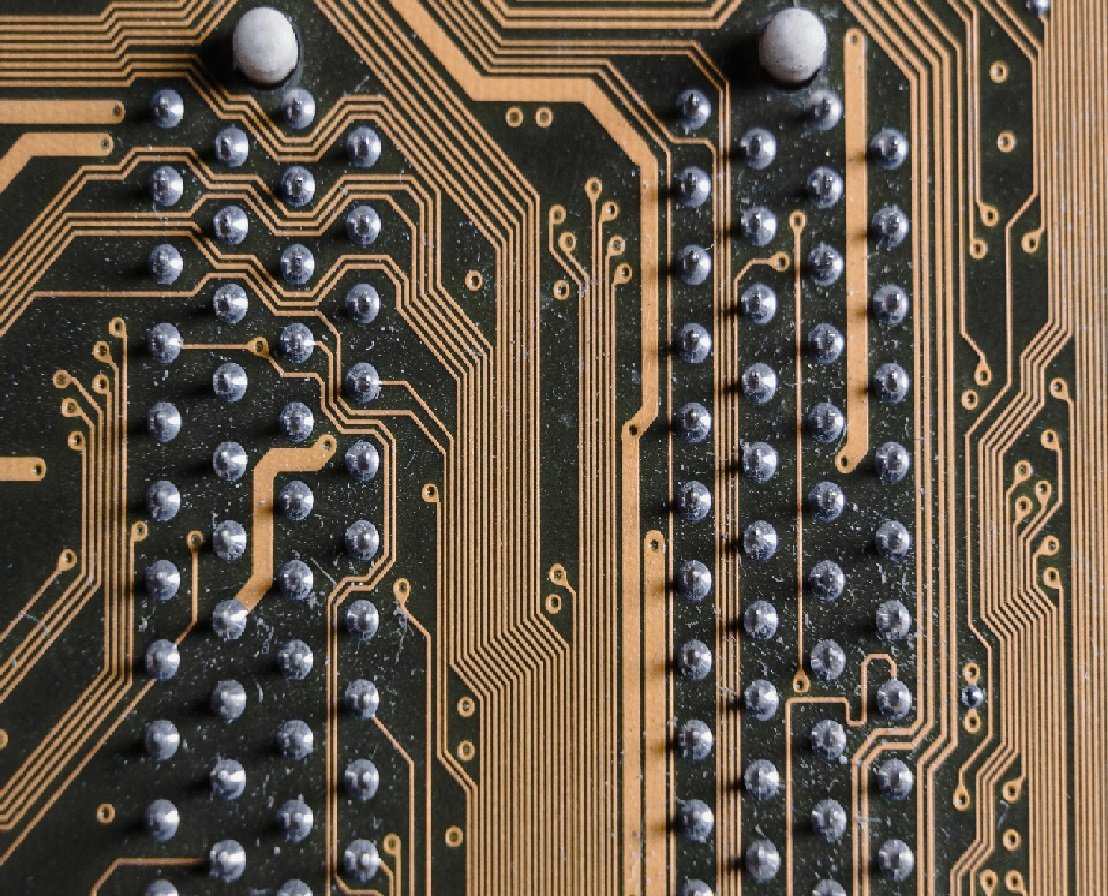

Introduction: Soldering is often associated with precision, craftsmanship, and attention to detail. But did you know that colors can also play a significant role in the soldering process? In this blog post, we will explore the various soldering techniques that utilize colors, and how they can enhance your soldering projects. From understanding the different types of soldering alloys to harnessing the power of fluxes, let's dive into the colorful world of soldering techniques. 1. Types of Soldering Alloys and their Colors: Soldering alloys are available in different compositions, each with its own unique properties. These alloys typically come in various colors, indicating their composition and melting points. For example: - Tin-Lead (Sn-Pb): Traditionally used in soldering, it is commonly characterized by a silvery-gray color. - Lead-Free: Compliance with environmental regulations led to the development of lead-free solder alloys, which can appear silver, gray, or even slightly yellowish. - Specialized Alloys: Alternative solder alloys such as silver solder, used in high-strength applications or precious metal solder, used in jewelry making, can exhibit colors ranging from silver to gold. Understanding the colors associated with different soldering alloys is crucial in selecting the right material for your specific project requirements and achieving optimal soldering results. 2. Fluxes and Their Colorful Magic: Flux is an essential component in soldering as it removes oxidation, improves wetting, and helps solder flow more easily. Depending on the type of flux used, it can have a wide range of colors, such as: - Rosin Flux: This type of flux is the most widely used in electronics soldering. It typically has an amber color and is known for its excellent fluxing properties. - Water-Soluble Flux: Often used in PCB assembly, this flux can appear clear or slightly greenish in color. - No-Clean Flux: As the name suggests, this type of flux requires no post-solder cleaning. It usually has a light yellow or clear appearance. The color of flux not only adds visual interest to your work but also helps indicate whether the flux has been properly applied and distributed on the soldering joint. 3. Heat Indicators: Colors also come into play as heat indicators in soldering techniques. For instance: - Temperature-Indicating Paste: This specialized paste contains temperature-sensitive compounds that change color when heated, helping the solderer monitor the temperature of the soldering joint during the soldering process. - Thermal Stress Indicating Paint: Used primarily in electronic device manufacturing, this paint can change color under specific heat conditions, allowing technicians to identify and resolve potential heat-related issues. These heat-indicating techniques are essential in preventing overheating and ensuring the integrity of the solder joint. Conclusion: Colors pervade the world of soldering techniques, adding both aesthetic appeal and functional value. Understanding the colors of different soldering alloys, fluxes, and heat-indicating materials is crucial in achieving successful soldering results and ensuring the longevity of your soldered connections. So, the next time you embark on a soldering project, embrace the colorful world of soldering techniques and elevate your craftsmanship to new heights. Happy soldering! To learn more, take a look at: http://www.colorsshow.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :