Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Role of Printed Circuit Boards in Commercial Jets: A Technological Marvel

Category : | Sub Category : Posted on 2023-10-30 21:24:53

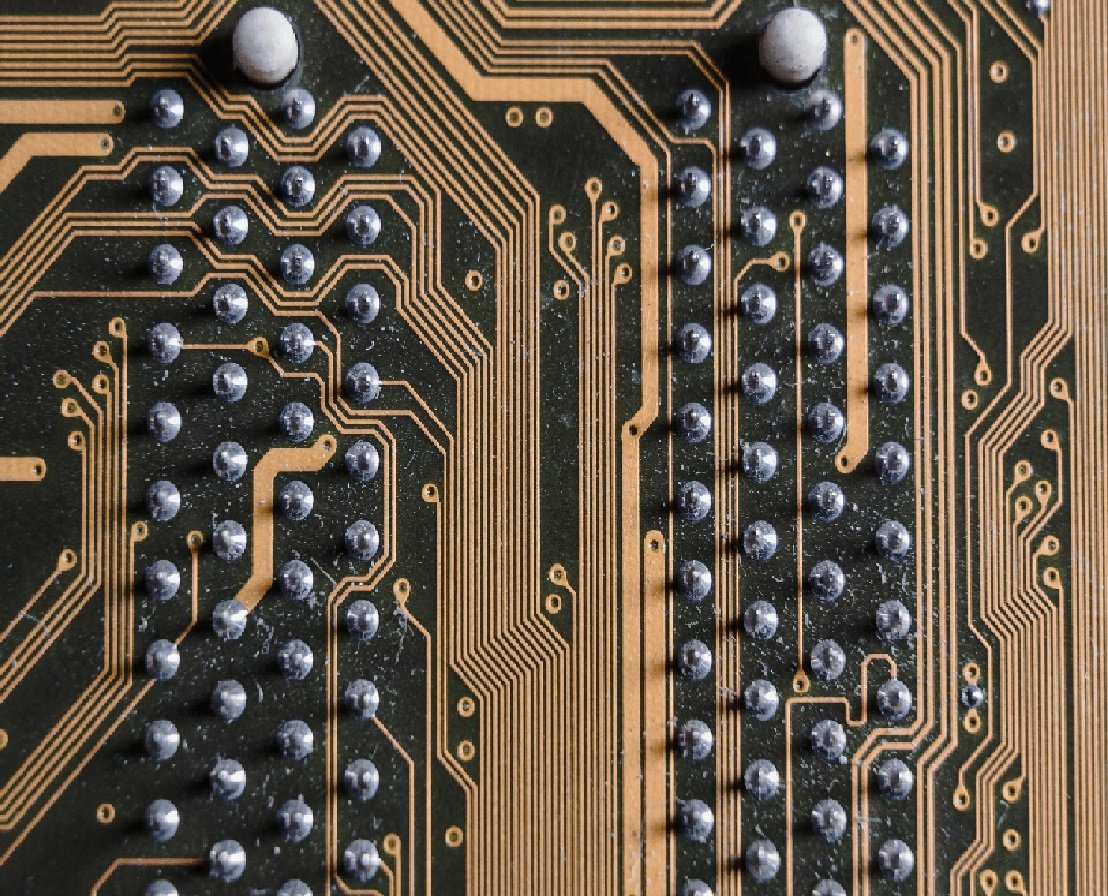

Introduction When it comes to commercial jets, many of us marvel at their size, speed, and ability to transport thousands of passengers across long distances. However, it's the intricate technological systems that make these marvels of engineering possible, and one crucial component that plays a significant role is the Printed Circuit Board (PCB). In this blog post, we will explore the importance of PCBs in commercial jets and how they contribute to their efficiency and safety. What are Printed Circuit Boards? A Printed Circuit Board, also known as a PCB, is a flat board made of non-conductive material with conductive tracks etched or printed onto its surface. It acts as a backbone for various electronic components in a wide range of devices, including commercial jets. PCBs provide mechanical support, electrical connections, and pathways for transmitting signals between different components. Why are PCBs essential in commercial jets? 1. Electrical Systems Integration: Commercial jets are equipped with complex electrical systems responsible for controlling various functions, such as flight navigation, communication, radar, and passenger entertainment systems. PCBs enable the integration of these systems, allowing for seamless communication and coordination between different components on the aircraft. 2. Weight Reduction and Space Optimization: PCBs are designed to be compact and lightweight while accommodating numerous components. By utilizing multilayer PCB designs, aerospace engineers can maximize space utilization on commercial jets, ensuring efficient use of valuable real estate within the aircraft's limited cabin and fuselage. 3. Signal Transmission: PCBs serve as reliable transmission channels for electrical signals that power critical systems in commercial jets. These signals include flight controls, avionics, weather radar, engine monitoring systems, and much more. PCBs ensure that signals reach the intended destinations without interference, ensuring smooth operations and enhancing passenger safety. 4. Temperature Control: The aerospace industry demands robust electronic systems that can withstand extreme temperatures, fluctuating pressures, and vibrations. PCB materials with high thermal conductivity and resistance to temperature variations are used to protect the intricate electronic components from thermal damage. 5. Redundancy for Reliability: Dedicated PCB designs enable commercial jets to have redundant systems that guarantee reliability and redundancy in case of failures. Redundancy ensures that critical systems, such as navigation, flight control, and communication, continue to operate without interruption, even if one or more PCBs encounter an issue. Conclusion Printed Circuit Boards play a crucial role in the operation and safety of commercial jets. From integrating complex electrical systems to optimizing space and weight, PCBs provide the backbone that allows for efficient communication and reliable functionality in these magnificent aircraft. With their ability to transmit signals seamlessly and withstand extreme conditions, PCBs contribute to enhanced passenger safety, ensuring a smooth and comfortable flight experience for all. As technology continues to advance, PCBs will undoubtedly evolve, becoming even more sophisticated and playing an increasingly critical role in the future of commercial aviation. also for more info http://www.jetiify.com To see the full details, click on: http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :