Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Mastering Soldering Techniques in Commercial Jets: A Critical Aspect of Aircraft Manufacturing

Category : | Sub Category : Posted on 2023-10-30 21:24:53

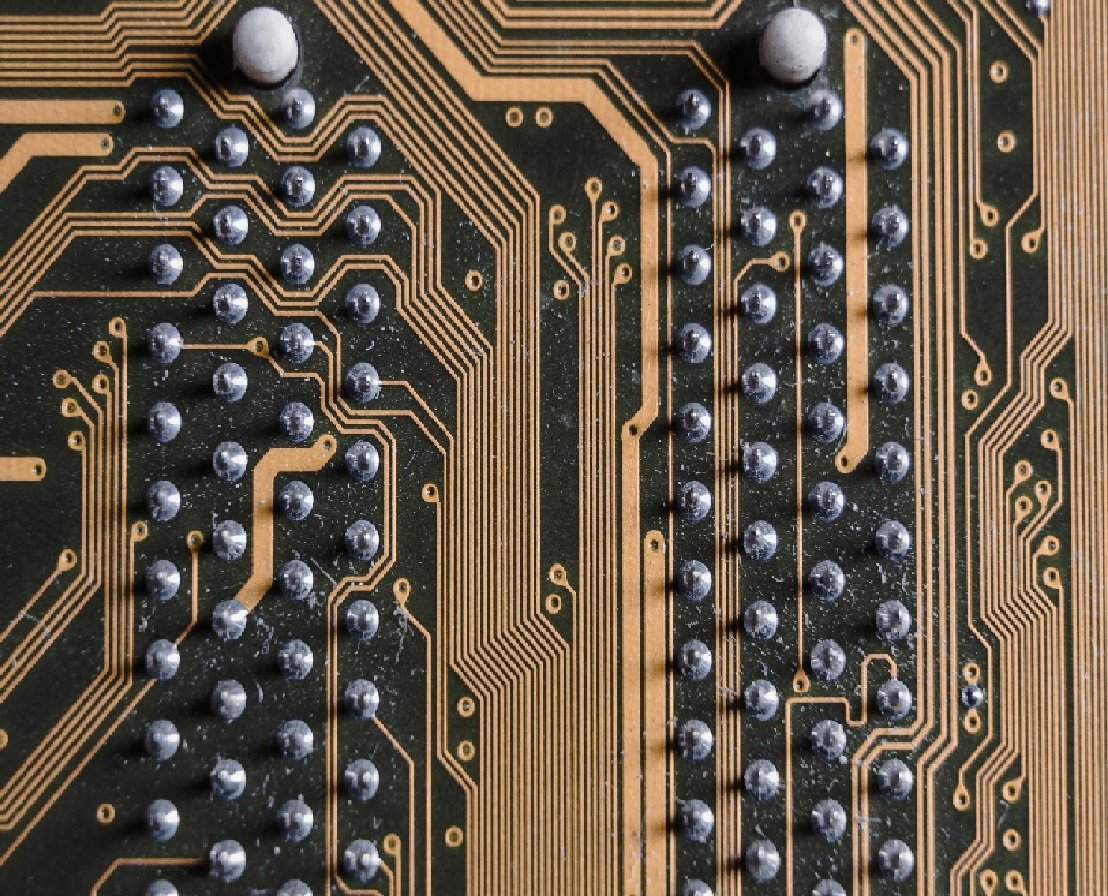

Introduction Soldering is a fundamental process in the manufacturing of commercial jets, playing a crucial role in ensuring the reliability and safety of the aircraft. It involves joining two or more metal components using a filler metal, known as solder, which has a lower melting point than the workpiece metals. In this blog post, we will explore the importance of soldering techniques in commercial jets and discuss the best practices employed by aerospace manufacturers. 1. Ensuring Structural Integrity The structural integrity of a commercial jet is of paramount importance. Soldering is used extensively to join electrical wiring, connectors, and other critical components together, ensuring a secure and reliable connection. Proper soldering techniques provide structural integrity, preventing components from becoming loose, disconnected, or creating potential hazards during flight. 2. Thermal Management Commercial jets operate under extreme conditions, with varying temperatures both inside and outside the aircraft. Soldering helps manage heat and electrical conductivity by dissipating generated heat and ensuring efficient power distribution. Manufacturers use advanced soldering techniques to guarantee proper solder flow, resulting in reduced thermal resistance and increased reliability in critical electrical systems. 3. Corrosion Protection The aviation industry faces immense challenges when it comes to corrosion. Soldering techniques, in combination with proper materials and protective coatings, contribute significantly to preventing corrosion in commercial jets. By using corrosion-resistant solder alloys and correctly applying them to join components, manufacturers mitigate the risk of performance-reducing or potentially catastrophic corrosion-related failures. 4. Solder Joint Quality The quality of solder joints directly impacts the reliability and longevity of electrical connections in commercial jets. Proper soldering techniques, such as controlled temperature, solder flow, and joint inspection, ensure consistent and robust solder joints. Manufacturers follow strict industry guidelines to achieve high-quality solder joints, including both visual inspection and non-destructive testing methods to guarantee the reliability of the joint. 5. Compliance with Industry Standards The aerospace industry is highly regulated, and compliance with industry standards is mandatory. Manufacturers of commercial jets must adhere to established guidelines, such as the National Aerospace Standards (NAS) and the Joint Electron Device Engineering Council (JEDEC) standards, to ensure the reliability and safety of soldered connections. These standards define crucial parameters for soldering techniques, including solder alloy composition, flux types, and process control. Conclusion Soldering techniques are integral to the manufacturing of commercial jets, contributing to structural integrity, thermal management, corrosion protection, and compliance with industry standards. Aerospace manufacturers employ advanced soldering techniques to create reliable and secure connections essential for the safe operation of commercial jets. As technology continues to evolve, the industry constantly seeks innovative soldering techniques to improve the performance and longevity of solder joints in future aerospace designs. Get more at http://www.jetiify.com For the latest research, visit http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :