Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Significance of Through-Hole Technology in Commercial Jets' Electronics

Category : | Sub Category : Posted on 2023-10-30 21:24:53

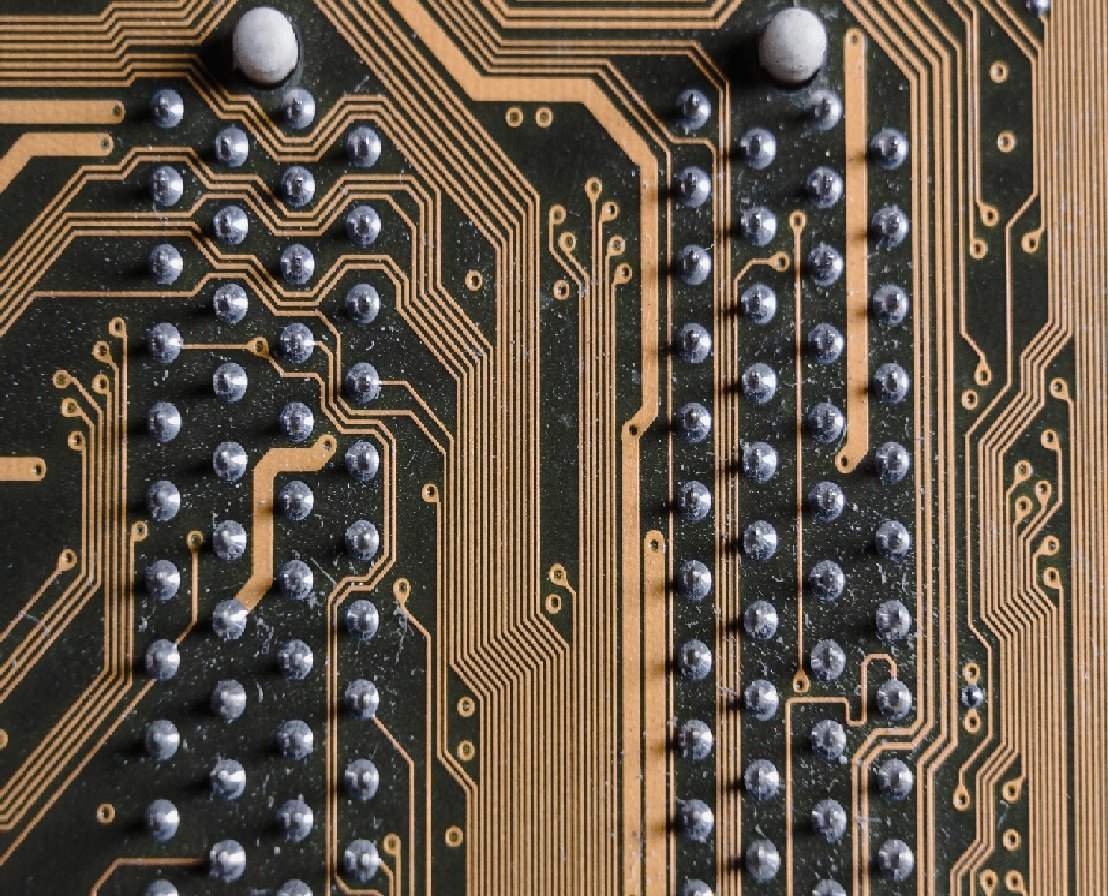

Introduction: Commercial jets have revolutionized the way we travel, connecting people across the globe in record time. Behind their efficient and seamless operation lies a labyrinth of advanced electronics, crucial for the safety, comfort, and performance of these high-tech marvels. One key component of commercial jet electronics is through-hole technology. In this blog post, we will explore the significance of through-hole technology and its pivotal role in the functioning of modern commercial jets. Understanding Through-Hole Technology: Through-hole technology, also known as thru-hole technology, is a method of mounting electronic components onto printed circuit boards (PCBs). Unlike surface-mount technology (SMT), which is widely adopted in consumer electronics, through-hole technology uses leads that pass through drilled holes in the PCB, creating a mechanical and electrical connection. Why Through-Hole Technology Matters in Commercial Jets: 1. Reliability and Durability: Commercial jets are subjected to a myriad of environmental stressors, including extreme temperatures, vibrations, and electromagnetic interference. Through-hole technology provides remarkable reliability and durability under these harsh conditions. The robust solder joints formed between the components and PCB ensure that vital systems remain operational throughout a jet's lifespan. 2. Resistance to Mechanical Stress: In-flight turbulence, rapid acceleration, and deceleration put significant mechanical stress on various components within a commercial jet. Through-hole technology offers enhanced resistance to mechanical stress due to the strong connection formed by the component leads and the PCB. This reduces the risk of component detachment or failure during flight, ensuring the continued operation of critical systems. 3. High Power and Heat Dissipation: Commercial jets require powerful electronics to handle complex systems such as avionics, flight controls, and communication equipment. Through-hole technology excels in handling high-power circuits and allows for efficient heat dissipation. Components with larger footprints and thicker leads can handle higher current flow, making it ideal for applications that demand optimum power handling capabilities. 4. Legacy and Retrofitting: While SMT has become the primary soldering method in modern electronics, commercial jets often have a long lifespan spanning decades. Many older aircraft may still rely on through-hole technology due to legacy systems and retrofitting requirements. Through-hole components can be easily replaced or upgraded when necessary, making them a practical choice for maintaining and modernizing existing aircraft. Conclusion: Through-hole technology plays a vital role in the electronics of commercial jets, ensuring reliability, durability, and resistance to mechanical stress. Although SMT has become prevalent in the consumer electronics industry, through-hole technology continues to be indispensable in the aerospace sector due to its ability to handle high power, dissipate heat efficiently, and its legacy compatibility. As new advancements emerge, it is imperative to strike a balance between newer technologies and the reliability offered by through-hole technology to maintain the safety and efficiency of commercial jets in the skies. To get a holistic view, consider http://www.jetiify.com Click the following link for more http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :