Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Power of Computer Vision in Electronic Testing and Measurement

Category : | Sub Category : Posted on 2023-10-30 21:24:53

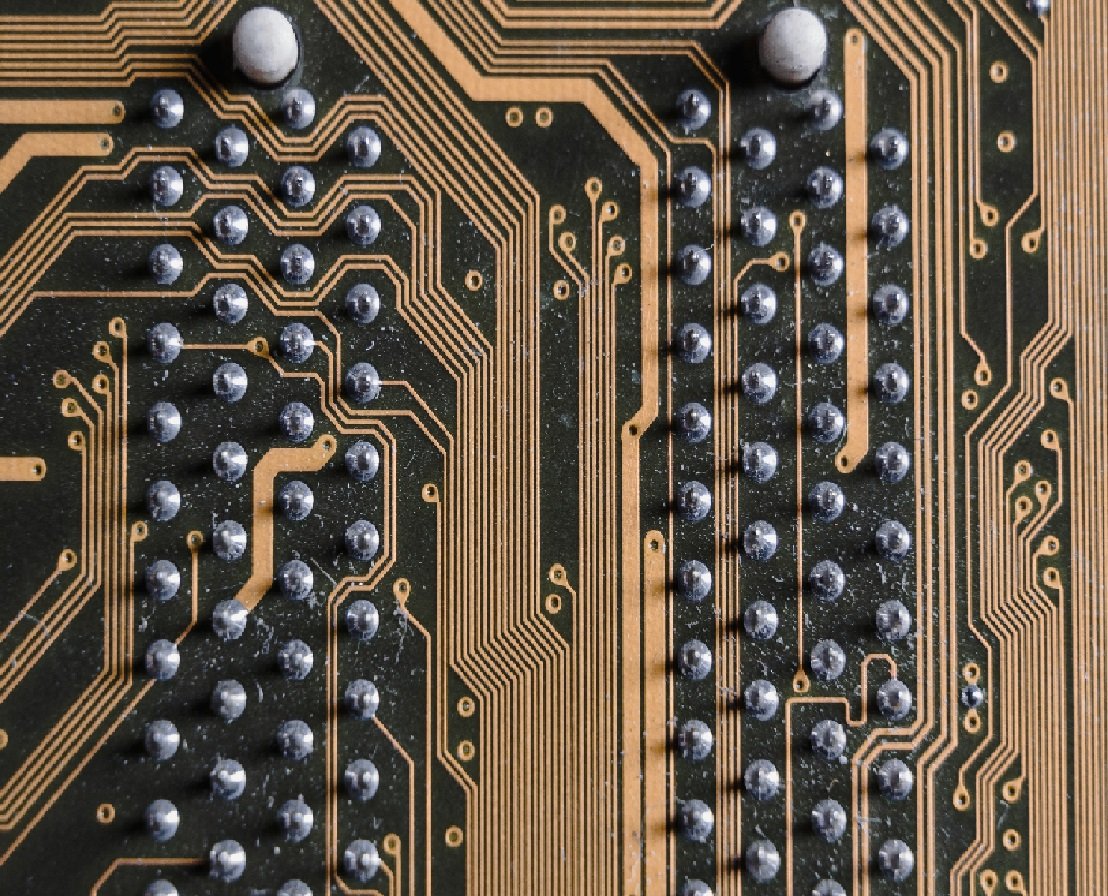

Introduction: Computer vision, a cutting-edge technology that enables computers to perceive and interpret visual information, has revolutionized various industries. One area where computer vision has proved to be invaluable is in electronic testing and measurement. Today, electronic devices are becoming increasingly complex, requiring advanced techniques to ensure their functionality, quality, and reliability. In this blog post, we will explore how computer vision plays a crucial role in the testing and measurement of electronic devices. Enhancing Quality Control: Quality control is a vital aspect of electronic device manufacturing. Computer vision systems allow automated inspection of electronic components during the production process. By analyzing images captured from cameras, these systems can detect flaws, defects, or inconsistencies in the manufacturing process that may affect the final product's performance. With computer vision, manufacturers can identify and rectify potential issues early on and maintain high quality standards. Testing Component Placement: Accurate component placement is critical for proper functioning of electronic devices. Computer vision algorithms can identify and verify the placement of different components on a printed circuit board (PCB). Through image recognition and pattern matching, computer vision systems can determine if components are correctly aligned, oriented, and soldered onto the PCB. This ensures that devices will function as intended, reducing the probability of failures or malfunctions. Automating Component Testing: In the past, manual testing of electronic components was a time-consuming and error-prone process. Computer vision has transformed this aspect of testing by enabling automation. With image processing algorithms, computer vision systems extract relevant information from electronic components, such as resistors, capacitors, and integrated circuits. By analyzing these images, the systems can identify defects or performance issues, ensuring the components meet the required specifications. This automation not only saves time but also improves the accuracy and efficiency of testing procedures. Detecting Circuit Troubleshooting: When troubleshooting electronic circuits, identifying faulty components or connections can be a challenging task. However, computer vision can simplify this process. By capturing images of the circuit and comparing them to a reference model, computer vision systems can identify deviations, breaks, or faults in the circuitry. This helps technicians to locate and repair issues swiftly, minimizing downtime and improving device reliability. Defect Recognition in Circuit Boards: Circuit boards are a complex network of interconnected electronic components. Even small defects in the circuitry can lead to significant performance issues. Computer vision algorithms can detect and classify defects such as short circuits, open circuits, and soldering defects on circuit boards. By using machine learning techniques, these systems can continually improve their defect recognition capabilities, ensuring more precise identification and faster defect resolution. Conclusion: Computer vision has revolutionized the testing and measurement processes in electronic device manufacturing. By leveraging its capabilities, manufacturers can enhance quality control, improve component placement accuracy, automate component testing, simplify circuit troubleshooting, and identify defects in circuit boards efficiently. As electronic devices continue to evolve and become more intricate, computer vision will undoubtedly play an increasingly crucial role in ensuring their reliable performance. Embracing this technology will not only enhance productivity but also deliver superior-quality devices to consumers. Looking for more information? Check out http://www.thunderact.com For additional information, refer to: http://www.vfeat.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :