Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

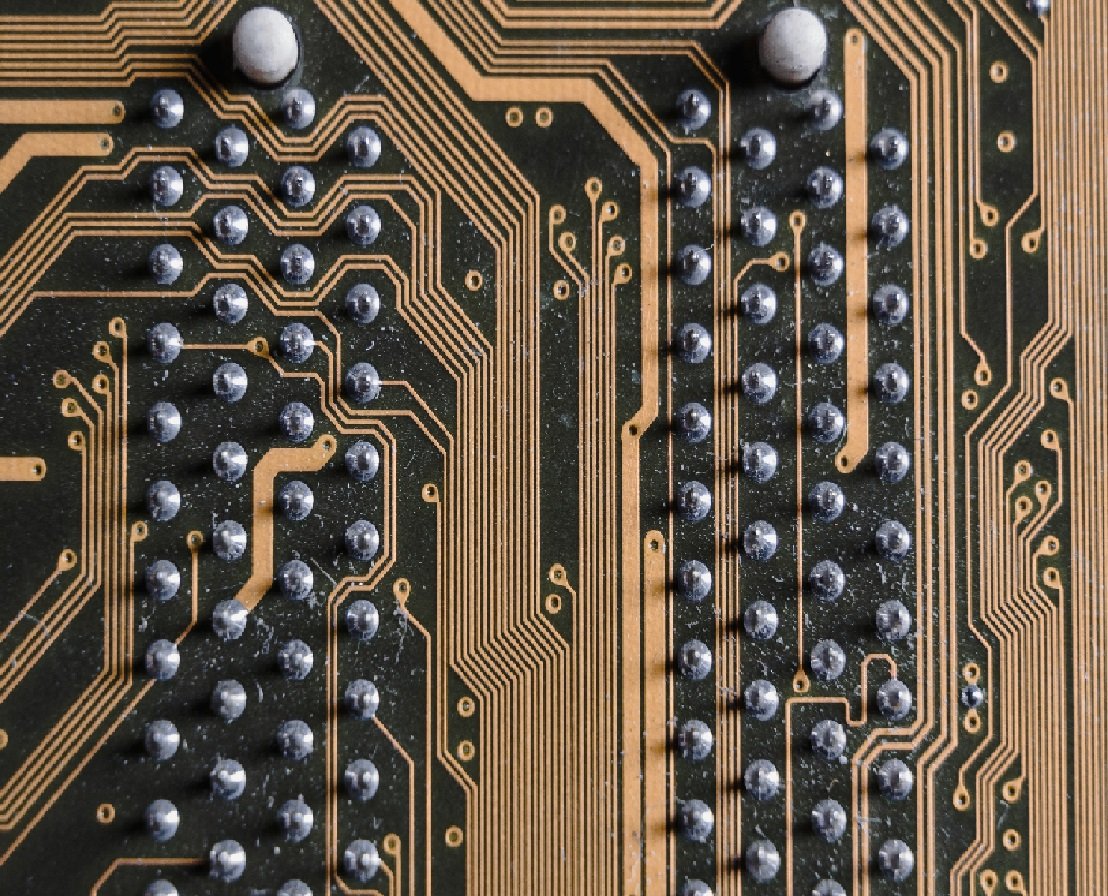

Enhancing PCB Design with Computer Vision Technology

Category : | Sub Category : Posted on 2023-10-30 21:24:53

Introduction: In the world of electronic engineering, PCB (Printed Circuit Board) design plays a crucial role in bringing innovative technologies to life. As the demand for compact and high-performance electronic devices continues to grow, engineers are constantly seeking advanced tools and technologies to streamline the PCB design process. One such technology that is revolutionizing the PCB design landscape is computer vision. By leveraging the power of artificial intelligence and image processing, computer vision software is enhancing the way engineers create, inspect, and optimize PCB designs. In this blog post, we will explore the role of computer vision in PCB design and how it is reshaping the industry. 1. The basics of PCB design software: Before delving into the intricacies of computer vision in PCB design, let's briefly discuss the basics of PCB design software. PCB design software provides engineers with a platform to create electronic schematics, layout components, and route connections in a virtual environment. Traditionally, engineers relied on manual processes and traditional design software to accomplish these tasks, often resulting in errors and time-consuming revisions. 2. Introducing computer vision in PCB design: Computer vision technology brings a new level of automation and efficiency to the PCB design process. By leveraging computer vision algorithms, engineers can extract meaningful information from PCB layouts and images, thus enabling faster and more accurate design modifications. Some of the key applications of computer vision in PCB design include: a. Component detection and placement: Computer vision algorithms can identify components in a PCB layout and accurately place them on the board, automatically aligning them with pre-defined design rules. b. Automated design rule checks: With computer vision, design rule checks can be performed automatically, ensuring that the PCB design adheres to electrical, mechanical, and manufacturing specifications. c. Defect detection and inspection: Computer vision algorithms can detect defects, such as solder shorts or open circuits, by analyzing high-resolution images of the assembled PCB. This enables early identification and rectification of manufacturing errors. d. Image recognition for component libraries: Computer vision can simplify the creation and management of component libraries by automatically identifying and classifying components based on their images. e. Reverse engineering: Computer vision allows engineers to reverse engineer PCB designs by analyzing physical PCB layouts and generating virtual representations with minimal manual intervention. 3. Benefits of computer vision in PCB design: The integration of computer vision technology in PCB design offers several significant benefits, including: a. Enhanced accuracy: Computer vision algorithms reduce human error in design processes, leading to more accurate and error-free PCB layouts. b. Time and cost savings: By automating repetitive design tasks, computer vision software significantly reduces design time and eliminates the need for expensive manual inspections. c. Improved manufacturability: Computer vision enables more precise and manufacturable design modifications, resulting in higher-quality PCBs and better production yields. d. Streamlined collaboration: With computer vision tools, designers, manufacturers, and testing teams can easily share and analyze PCB layouts and images, enabling seamless collaboration and faster decision-making. 4. Advancements and future prospects: Computer vision technology in PCB design is continuously evolving. Advancements in deep learning algorithms and neural networks are further enhancing the accuracy and capabilities of computer vision software. In the future, we can expect to see even more sophisticated applications, such as real-time defect detection during manufacturing and augmented reality-based PCB design environments. Conclusion: As the field of PCB design continues to evolve, computer vision is becoming an indispensable tool for engineers. By automating labor-intensive tasks, increasing accuracy, and improving collaboration, computer vision is revolutionizing the way PCBs are designed and manufactured. Engineers and electronic enthusiasts can embrace this technology to unlock a new level of efficiency and innovation in their PCB design projects. To get a holistic view, consider http://www.thunderact.com Explore expert opinions in http://www.vfeat.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :