Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Unveiling the Power of Computer Vision in Printed Circuit Boards

Category : | Sub Category : Posted on 2023-10-30 21:24:53

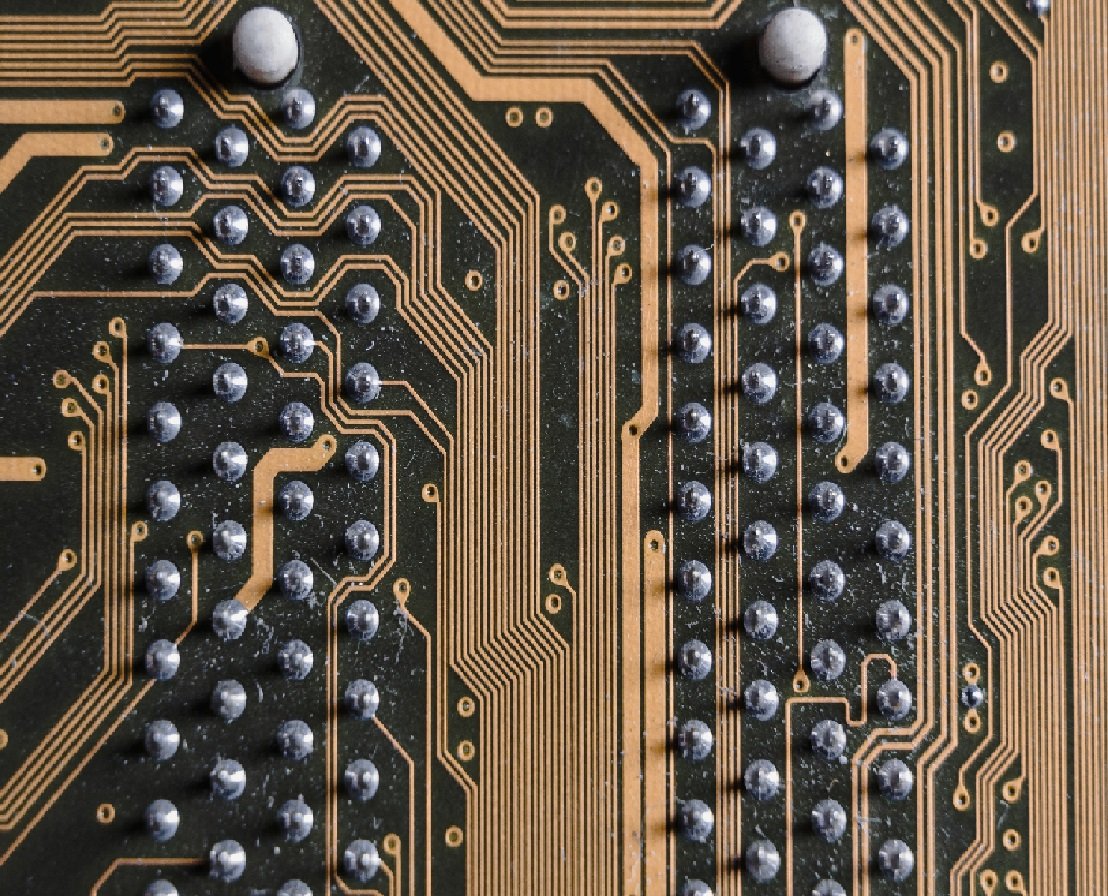

Introduction: Printed circuit boards (PCBs) are the backbone of modern electronic devices, enabling the seamless flow of electrical signals and ensuring their smooth operation. As technology continues to advance, the complexity of PCBs is increasing, posing new challenges in terms of inspection, fault detection, and quality control. Enter computer vision, a cutting-edge technology that is revolutionizing the way we inspect and analyze PCBs. In this article, we will delve into the world of computer vision and explore its applications in the realm of printed circuit boards. 1. Enhanced Inspection: Traditionally, human inspectors have been responsible for visually examining PCBs to detect defects such as soldering issues, component misalignment, or faulty traces. However, manual inspection is time-consuming, prone to human error, and cannot keep up with the growing demand for more reliable and efficient inspection processes. By leveraging computer vision, automated inspection systems can quickly and accurately detect defects with a high degree of precision. Using sophisticated algorithms and machine learning techniques, these systems analyze images of PCBs to identify deviations, ensuring that only flawless circuit boards are assembled. 2. Component Placement Verification: Accurate component placement is crucial for reliable PCB functionality. In large-scale manufacturing, ensuring that each component is placed correctly and aligned perfectly is a daunting task fraught with the potential for errors. Computer vision, equipped with object recognition algorithms, can identify and verify the correct placement of components on PCBs. By comparing the actual placement with design specifications, any inconsistencies or misalignments can be quickly detected and rectified, preventing potential malfunctions or performance issues. 3. Quality Control and Defect Classification: PCB manufacturing involves multiple stages, each susceptible to errors or defects. Computer vision systems can be employed at various checkpoints in the manufacturing process to carry out quality control and defect classification tasks. By employing pattern recognition techniques, the system can analyze the PCB surface for anomalies, such as scratches, cracks, or variations in color, and categorize them according to predefined defect types. This approach considerably reduces human effort and accelerates the quality control process, minimizing the risk of faulty PCBs reaching the market. 4. Traceability and Real-time Monitoring: In industries where traceability is critical, such as automotive or aerospace, computer vision plays a vital role in enabling real-time monitoring and accurate identification of PCBs throughout the production process. By incorporating unique identification markers or barcodes on PCBs, computer vision systems can track their movement, ensuring that they follow the intended manufacturing flow. This level of tracking enhances efficiency, reduces the risk of errors, and facilitates inventory management. 5. Future Possibilities: As computer vision technology continues to evolve, it holds immense potential for further advancement in the realm of PCBs. One such possibility is the application of deep learning algorithms to identify more complex defects or anomalies with increased accuracy. Additionally, the integration of computer vision with robotics offers the potential for automated assembly and inspection processes, revolutionizing the PCB manufacturing industry. Conclusion: Computer vision is a game-changer in the field of printed circuit boards, providing unprecedented accuracy and efficiency in inspection, defect detection, and quality control. Its ability to analyze images, identify components, and track PCBs enables significant advancements in manufacturing processes, reducing the risk of faulty products and ensuring superior performance. As technology continues to evolve, computer vision will undoubtedly play an even more significant role in the future of PCB manufacturing, revolutionizing the industry and enhancing our electronic devices' reliability. this link is for more information http://www.thunderact.com Want to expand your knowledge? Start with http://www.vfeat.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :