Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Safeguarding Data Privacy: Best Practices in Soldering Techniques

Category : | Sub Category : Posted on 2023-10-30 21:24:53

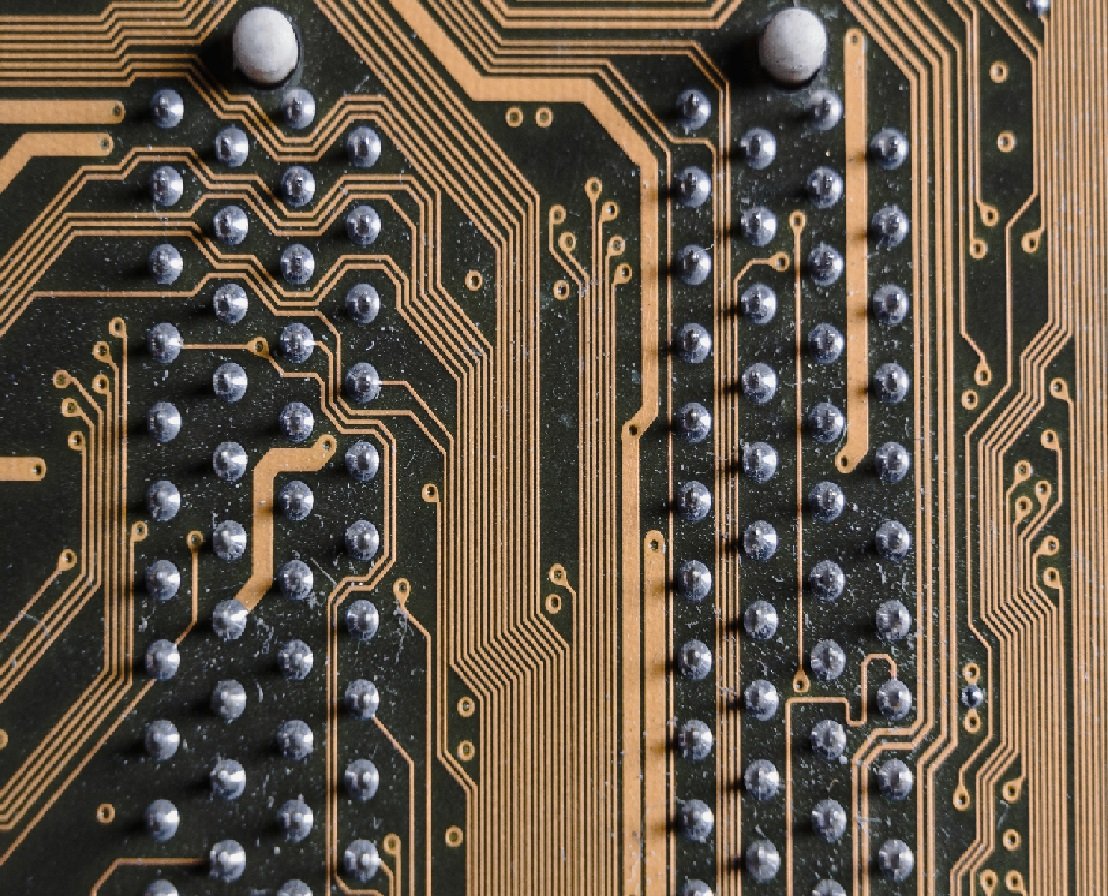

Introduction In today's digital era, data privacy has become a pressing concern for individuals and organizations alike. As technology continues to advance, it is crucial to ensure that sensitive information remains protected from unauthorized access or breaches. While data privacy may seem unrelated to soldering techniques at first glance, this article aims to shed light on how proper soldering practices can contribute to preserving the security and integrity of electronic devices. Understanding Data Privacy in Soldering Soldering is the process of joining two or more electrical components using a conductive filler material called solder. Although it may seem like a simple task, soldering plays a critical role in the production and maintenance of electronic devices, from smartphones to medical implants. When it comes to data privacy, soldering techniques can impact the security measures implemented at the hardware level. Encryption, secure communication protocols, and access control mechanisms may protect data within the software, but a compromised hardware component can compromise the overall security of the system. Best Practices for Soldering to Ensure Data Privacy 1. ESD (Electrostatic Discharge) Protection: Electrostatic Discharge poses a significant threat to sensitive electronic components, potentially altering their behavior or permanently damaging them. To protect against ESD, it is essential to implement proper grounding techniques and use ESD-safe tools and equipment. By minimizing the risk of ESD, data integrity and privacy can be maintained during the soldering process. 2. Component Placement and Heat Management: During soldering, heat causes the solder to melt, allowing components to fuse. However, excessive heat can damage nearby components and affect their functionality. Proper component placement, ensuring sufficient spacing between sensitive components, and careful heat management are crucial to prevent data corruption or malfunctioning due to overheating. 3. Tin Whiskers Prevention: Tin whiskers are microscopic metallic fibers that can grow from solder joints over time. If they become long enough, they may inadvertently bridge electronic contacts, leading to short circuits and potential data loss or corruption. To minimize the risk of tin whiskers, using lead-free solder and ensuring appropriate cleanliness and surface preparation are recommended. 4. Proper Solder Joint Inspection: After soldering, thorough inspection of the joints is critical to identify any potential issues. Cold solder joints, insufficient solder, or bridges between adjacent electrical contacts can compromise the integrity of data transmission or storage. By incorporating both visual inspection and electrical testing methods, the quality and reliability of solder joints can be ensured, thereby safeguarding against data breaches. Conclusion In an age where data privacy is paramount, even seemingly unrelated processes like soldering can significantly impact the security and integrity of electronic devices. Implementing best practices such as ESD protection, proper heat management, tin whisker prevention, and thorough solder joint inspection contributes to preserving data privacy throughout a device's lifecycle. By adopting these practices, manufacturers, technicians, and hobbyists can play an essential role in building robust and secure hardware systems that protect sensitive information. Together, let's prioritize data privacy and ensure that our soldering techniques align with the highest standards of security in today's technological landscape. For more information check: http://www.privacyless.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :