Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Unlocking the Skies: DIY Aircraft Printed Circuit Boards

Category : | Sub Category : Posted on 2023-10-30 21:24:53

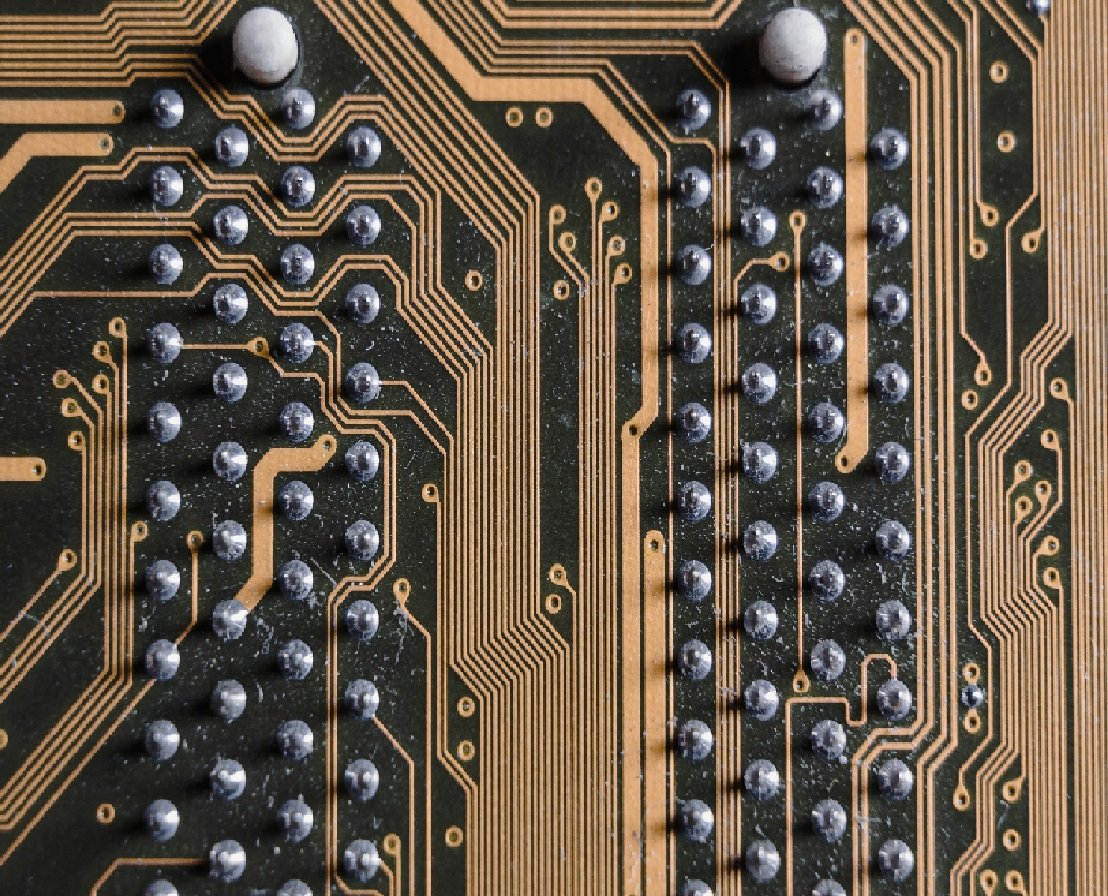

Introduction In the world of aviation enthusiasts and amateur pilots, harnessing advanced technology to build your own aircraft has become an exciting and compelling endeavor. One crucial component that plays a vital role in the functioning of these DIY aircraft is the printed circuit board (PCB). In this article, we will explore the ins and outs of DIY aircraft printed circuit boards, highlighting their importance and sharing tips for success. Understanding DIY Aircraft Printed Circuit Boards A printed circuit board, commonly known as a PCB, acts as the central nervous system of any electronic device, including aircraft. It is responsible for establishing connections and creating pathways for proper electrical flow. In the case of DIY aircraft, PCBs enable seamless integration and communication between various systems, such as navigation, communication, and power distribution. Benefits of DIY Aircraft Printed Circuit Boards 1. Customization: One of the significant advantages of DIY aircraft PCBs is the ability to tailor them to specific requirements. With market-available PCBs, you may need to compromise on certain aspects due to limited choices. However, by creating your own PCBs, you have the freedom to design them according to the unique specifications of your aircraft, ensuring optimal performance. 2. Cost-Efficiency: While developing your aircraft's PCB may initially require an investment in equipment and materials, it can lead to long-term cost savings. Commercially available PCBs can be expensive, especially for those working on a tight budget. By making your PCBs, you can significantly reduce costs and allocate resources to other essential aspects of your DIY aircraft project. Tips for Success in DIY Aircraft PCB Projects 1. Knowledge is Key: Before embarking on a DIY aircraft PCB project, ensure you have a solid understanding of electronics and PCB design. Familiarize yourself with concepts like schematics, board layout, and component placement. There are numerous online resources, tutorials, and communities tailored to PCB design, which can help enhance your knowledge. 2. Utilize Design Software: To create professional-grade PCBs, utilize specialized software such as Eagle, Altium Designer, or KiCad. These tools provide a range of features to facilitate PCB design, such as schematic capture, component libraries, and PCB layout. 3. Test and Iterate: Testing is an essential part of any DIY aircraft project, especially when it comes to PCBs. Use multimeters, oscilloscopes, and testing kits to verify the functionality and performance of your PCB before integrating it into your aircraft. Iteration and refinement based on testing results are crucial for achieving high reliability. 4. Seek Expert Advice: If you're new to DIY aircraft PCBs, reaching out to experienced enthusiasts or professionals can provide invaluable insights. Online communities, forums, and local aviation clubs often have members with expertise in PCB design who are willing to offer guidance and share their experiences. Conclusion Building your own DIY aircraft involves various technical aspects, and the creation of customized printed circuit boards is a vital one. While it may seem daunting at first, taking the time to understand the fundamentals of PCB design, utilizing specialized software, conducting thorough testing, and seeking guidance from knowledgeable individuals will greatly increase your chances of success. Remember, DIY aircraft PCBs offer the flexibility to customize your aircraft's electrical system while reducing costsan exciting prospect for aviation enthusiasts ready to take to the skies. Visit the following website http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :