Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Mastering DIY Aircraft Electronics with Surface Mount Technology

Category : | Sub Category : Posted on 2023-10-30 21:24:53

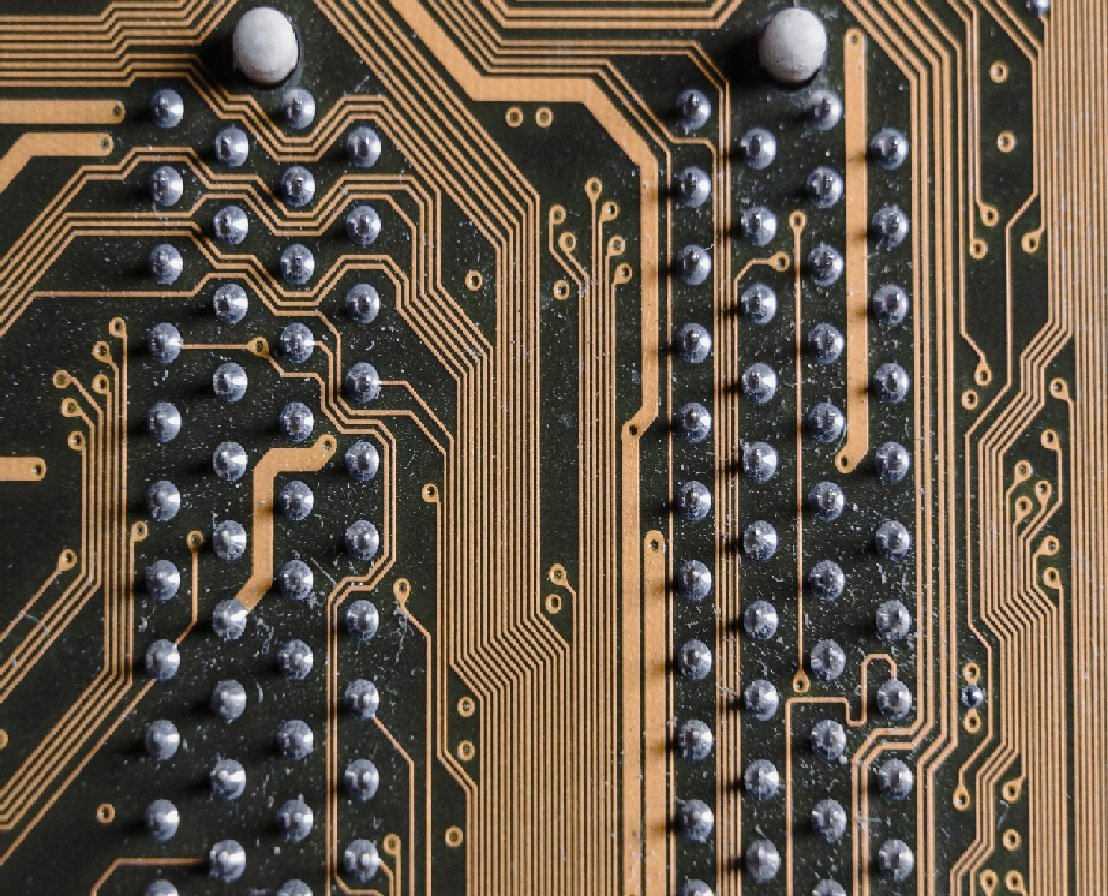

Introduction: In the world of DIY aircraft building, having reliable and efficient electronics is crucial for smooth operations and safe flights. With the advancements in technology, surface mount technology (SMT) electronics have become the go-to choice for many aircraft enthusiasts. In this blog post, we will explore the benefits of SMT electronics for aircraft, discuss the challenges associated with working on SMT components, and offer some tips to help you master the art of DIY aircraft SMT electronics. Benefits of Surface Mount Technology Electronics in Aircraft: 1. Space-saving: SMT components are significantly smaller in size compared to their through-hole counterparts, allowing for more space-efficient designs. This is especially advantageous in aircraft, where space is limited and every ounce counts. 2. Weight reduction: The smaller size and reduced weight of SMT components contribute to a lighter overall aircraft, improving fuel efficiency and performance. 3. Enhanced reliability: SMT components are designed to have lower parasitic capacitance and inductance, reducing the risk of electromagnetic interference and improving the overall reliability of the electronic systems. Challenges Associated with Working on SMT Components: While SMT electronics offer numerous benefits, they also come with their own set of challenges. Some common challenges faced when working with SMT components for aircraft include: 1. Component handling: SMT components are delicate and require careful handling to avoid damage. Special tools and techniques are often necessary to accurately place components onto the PCB. 2. Soldering intricacies: Soldering SMT components requires precision and attention to detail. The smaller size of the components poses a challenge in achieving proper solder joints, and the risk of solder bridges and tombstoning is higher. Tips to Master DIY Aircraft SMT Electronics: 1. Invest in the right tools and equipment: To work with SMT components effectively, investing in high-quality tools is crucial. SMT tweezers, a microscope or magnifying glass, and a temperature-controlled soldering iron are essentials for successful SMT work. 2. Practice proper soldering techniques: Soldering SMT components requires skill and practice. Ensure that you have appropriate soldering training before attempting intricate SMT soldering tasks. Proper soldering techniques, such as using the right amount of solder and ensuring component alignment, are crucial for reliable connections. 3. Use a stencil for solder paste: Soldering SMT components often involves the use of solder paste. Using a stencil to accurately apply solder paste to the PCB helps to ensure consistent and reliable solder joints. 4. Consider using a reflow oven or hot air rework station: While hand-soldering SMT components is possible, using a reflow oven or hot air rework station can provide more consistent results. These tools allow for precise temperature control and uniform heating, resulting in reliable solder joints. Conclusion: Mastering the art of DIY aircraft SMT electronics can unlock a world of possibilities for your aircraft building projects. The space-saving design, weight reduction, and enhanced reliability offered by SMT components are highly beneficial. However, it is essential to understand and overcome the challenges associated with working on SMT components. By investing in the right tools and equipment, practicing proper soldering techniques, and considering the use of reflow ovens or hot air rework stations, you can confidently incorporate SMT electronics into your DIY aircraft projects, taking your aircraft building skills to new heights. Get a comprehensive view with http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :