Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Taking DIY Aircraft to New Heights with Through-Hole Technology in Electronics

Category : | Sub Category : Posted on 2023-10-30 21:24:53

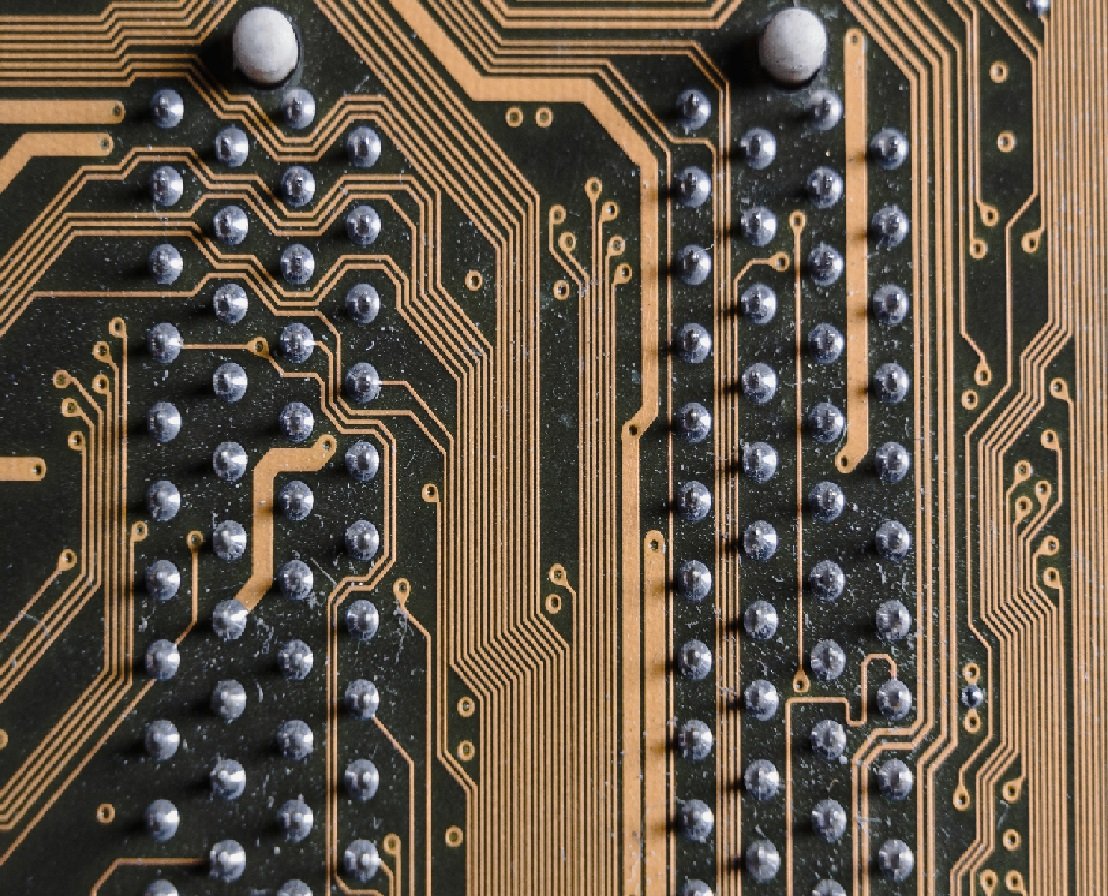

Introduction: In the world of DIY aircraft enthusiasts, innovation and creativity know no bounds. From building model planes to designing and constructing full-scale aircraft, hobbyists are constantly pushing the boundaries of what is possible. One key component that plays a crucial role in this process is through-hole technology in electronics. In this blog post, we will explore the fascinating world of DIY aircraft and how through-hole technology in electronics can enhance your projects. Understanding Through-Hole Technology: Through-hole technology is a popular method used to mount electronic components onto printed circuit boards (PCBs). Unlike surface-mount technology, which involves soldering components directly onto the surface of the board, through-hole technology involves inserting leads or pins of the electronic components through holes in the PCB and soldering them on the other side. This method provides better stability, durability, and ease of repair, making it a favored choice for DIY aircraft enthusiasts. Advantages of Through-Hole Technology in DIY Aircraft: 1. Enhanced Durability: DIY aircraft often have to withstand harsh environmental conditions, including strong winds, vibrations, and potential impact. Using through-hole technology ensures that components are securely mounted on the PCB, offering increased resistance to mechanical stress. 2. Ease of Repair and Replacement: When building your own aircraft, it's inevitable that parts will occasionally fail or need replacement. Through-hole technology allows for easy removal and replacement of components, saving significant time and effort in repair and maintenance. 3. Stability during Extreme Flight Maneuvers: Advanced DIY aircraft projects often involve high-speed maneuvers and aerobatics. Through-hole technology provides a higher degree of stability and reliability, ensuring that critical electronic components stay put even during extreme flight conditions. Utilizing Through-Hole Technology in DIY Aircraft Electronics: 1. Choosing the Right Components: Opt for through-hole components when selecting electronic parts for your DIY aircraft projects. These components have pre-formed leads that make them ideal for insertion into PCBs. 2. Planning the PCB Layout: Before starting the assembly process, carefully plan the layout of your PCB. Consider factors like component placement, signal paths, and minimizing the distance between components to optimize the design for both performance and ease of assembly. 3. Mastering Soldering Techniques: Proper soldering techniques are crucial in through-hole technology. Ensure that you have the right tools, such as a soldering iron with adjustable temperature settings and a soldering station with a good-quality tip. Practice soldering on scrap components to refine your skills before working on your actual project. 4. Testing and Quality Assurance: After soldering the components onto the PCB, thoroughly test each connection using a multimeter and perform functional tests to ensure the electronics are working as intended. Regularly inspect your aircraft's electronics for any signs of damage or loose connections to maintain optimal performance. Conclusion: Through-hole technology in electronics has revolutionized the DIY aircraft community, providing enhanced durability, ease of repair, and stability during extreme flight maneuvers. By incorporating this technology into your projects, you can take your DIY aircraft to new heights of performance and reliability. Remember to choose the right components, plan your PCB layout carefully, master soldering techniques, and perform thorough testing to ensure top-notch results. So, embrace through-hole technology and embark on your next DIY aircraft adventure with confidence! click the following link for more information: http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :