Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

A Beginner's Guide to DIY Drone Printed Circuit Boards

Category : | Sub Category : Posted on 2023-10-30 21:24:53

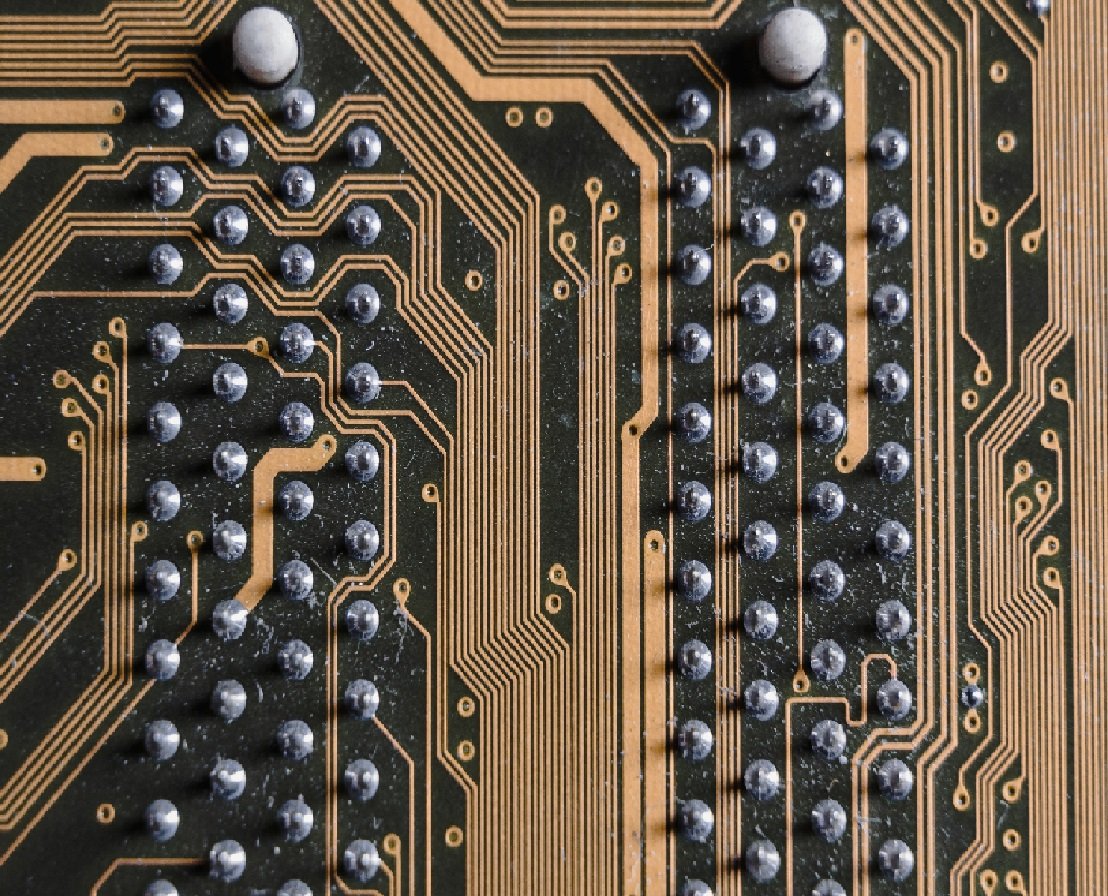

Introduction: Drones have become increasingly popular in recent years, offering exciting opportunities for aerial photography, videography, and even racing. While many drone enthusiasts choose to purchase ready-made drones, there is a growing community of DIY enthusiasts who prefer to build their drones from scratch. If you are one of these enthusiasts, this guide will walk you through the process of creating your DIY drone using printed circuit boards (PCBs). What is a PCB and why use it in DIY drones? A printed circuit board (PCB) is a flat board made of non-conductive material (typically fiberglass) with thin layers of copper conductive material etched onto its surface. These copper traces serve as pathways for electronic components to be soldered onto the board. By using a PCB in your DIY drone, you can easily connect and organize all the necessary electronic components, making the build process more efficient and reliable. Designing your DIY drone PCB: 1. Research and Planning: Start by researching the components you will need for your drone, such as flight controller, motors, ESCs, receiver, and battery. Once you have a clear understanding of the components, you can start designing your PCB layout. 2. Software Selection: Choose a PCB design software that suits your skill level and budget. Some popular options include Eagle, KiCad, and Altium Designer. These software tools allow you to create the schematic and layout for your drone's PCB. 3. Schematic Design: Begin by creating the schematic diagram, which represents the connectivity and functionality of your drone's electronic components. Make sure to properly connect all the components and add any necessary external connections. 4. PCB Layout Design: Once you have the schematic, start designing the physical layout of your PCB. Carefully place the components in their appropriate locations, considering factors such as component orientation, size, and signal integrity. Manufacturing and Assembly: 1. Manufacturing Options: After finalizing your PCB design, you have two main options for manufacturing: etching the PCB yourself or outsourcing the manufacturing to a professional PCB manufacturer. Etching at home requires some specialized equipment and skills, while outsourcing ensures higher quality and precision. 2. PCB Assembly: Once you have your manufactured PCB, you can start assembling the components onto the board. Take caution to follow proper soldering techniques and guidelines to ensure a good electrical connection. Testing and Troubleshooting: After assembling your PCB, it's crucial to thoroughly test your DIY drone before taking it for a flight. Make sure all the components are properly working, verify the connections, and check for any short circuits or loose connections. Troubleshoot and fix any issues that arise during testing. Conclusion: Building your DIY drone using printed circuit boards can be a rewarding experience that allows you to customize and optimize your aircraft. Utilizing PCBs simplifies the wiring process, making it easier for beginners to assemble a reliable drone. By following the design, manufacturing, and testing steps outlined in this guide, you can create a DIY drone that meets your specific needs and takes your drone-building skills to new heights! For a different take on this issue, see http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :