Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

DIY Experiments Gone Wrong: A Guide to Electronics Failure Analysis

Category : | Sub Category : Posted on 2023-10-30 21:24:53

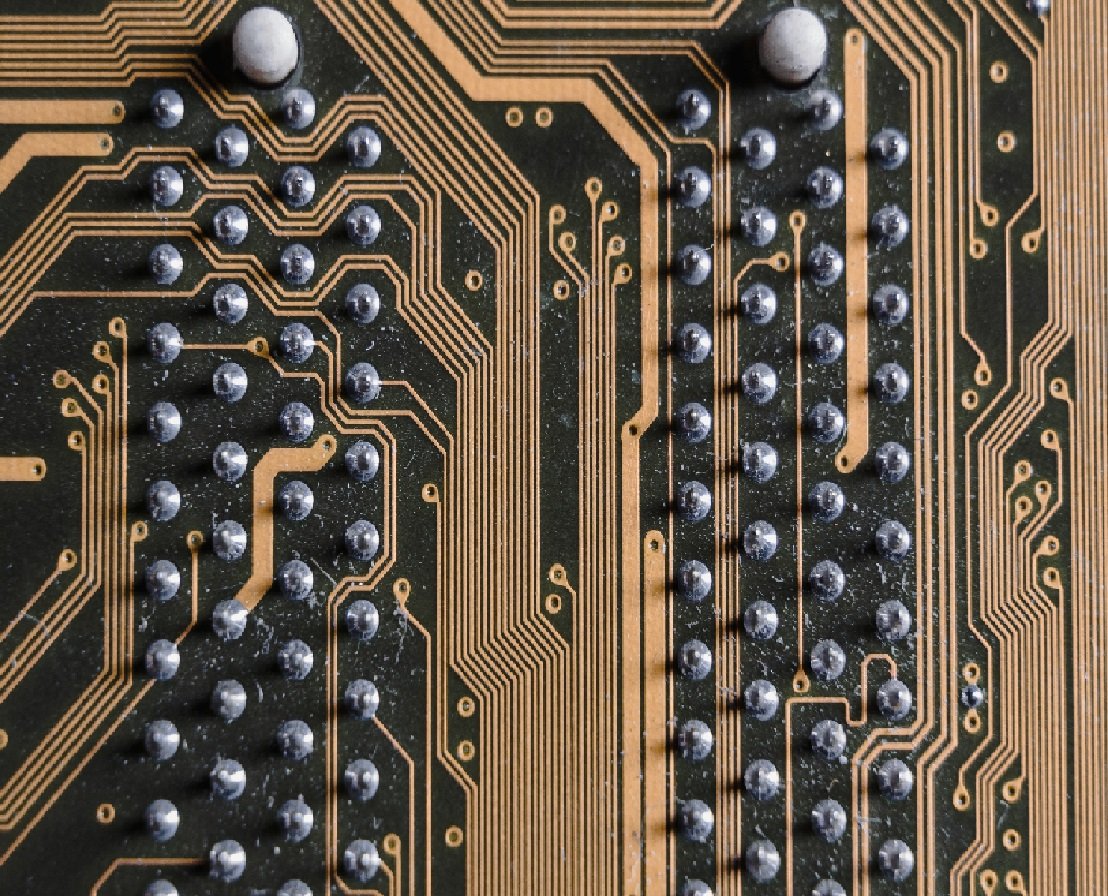

Introduction: DIY experiments can be a fun and rewarding way to learn more about electronics. However, like any experiment, there's always a chance of failure. Whether you're a beginner or a seasoned DIY enthusiast, understanding the reasons behind electronics failure can be crucial in enhancing your troubleshooting skills. In this blog post, we will explore common reasons for electronics failure and provide a comprehensive guide to analyzing and addressing them. 1. Understanding the Basics: Before delving into failure analysis, it's important to have a strong foundation in electronics basics. Familiarize yourself with components, circuitry, and wiring to better comprehend potential failure points. This knowledge will prove invaluable when it comes to diagnosing and fixing issues. 2. Common Electronics Failures: a) Overheating: One of the most prevalent causes of electronics failure is excessive heat. Components that aren't adequately cooled can overheat and malfunction. Ensure proper ventilation and cooling mechanisms to prevent this issue. b) Power Surges: Power surges or voltage spikes can fry delicate components. Protect your circuits by using surge protectors, voltage regulators, or even an uninterruptible power supply (UPS) to safeguard against voltage fluctuations. c) Poor Connections: Loose or poorly soldered connections can lead to intermittency or complete failure of circuits. Pay close attention to the quality of your connections and invest time in perfecting your soldering techniques. d) ESD Damage: Electrostatic discharge (ESD) can cause irreparable damage to sensitive electronic components. Always handle components and circuitry with proper grounding techniques and employ ESD safe practices. 3. Troubleshooting and Failure Analysis Process: a) Identify the Symptoms: Carefully observe and document the symptoms exhibited by the failed electronics. Pay attention to any unusual smells, sounds, or visual anomalies. Accurately describing the symptoms will help you diagnose the issue more effectively. b) Start with the Power Source: Check the power supply and ensure it is delivering the correct voltage to the circuit. Additionally, test the power source with a multimeter to validate its functionality. c) Inspect Components: Visually inspect all components for signs of physical damage. Look for burnt or bulging capacitors, charred resistors, or loose connections. Consider using a magnifying glass or a microscope to detect any microscopic flaws. d) Utilize Testing Equipment: Make use of various testing tools such as multimeters, oscilloscopes, or logic analyzers to measure voltages, check signals, and analyze data. These tools can help you pinpoint the faulty components or areas within the circuit. e) Replace and Test: Once you have identified the culprit component, replace it with a new one. Carefully follow the manufacturer's instructions and avoid any mishandling. Test the circuit after replacement to ensure proper functionality. 4. Learning from Failure: Remember, failure is an integral part of the learning process. Keep a log of your experiments, documenting both successes and failures. Analyze your failures to gain insights into what went wrong and how it can be avoided in future projects. Embrace failure as an opportunity to grow and improve your skills. Conclusion: By understanding the common causes of electronics failure and having a structured approach to failure analysis, you can become a more adept DIY electronics enthusiast. Remember to take precautions, learn from your mistakes, and practice perseverance. Happy troubleshooting and may your future DIY experiments be resounding successes! For the latest research, visit http://www.improvedia.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :