Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

A Comprehensive Guide to DIY Home Printed Circuit Boards

Category : | Sub Category : Posted on 2023-10-30 21:24:53

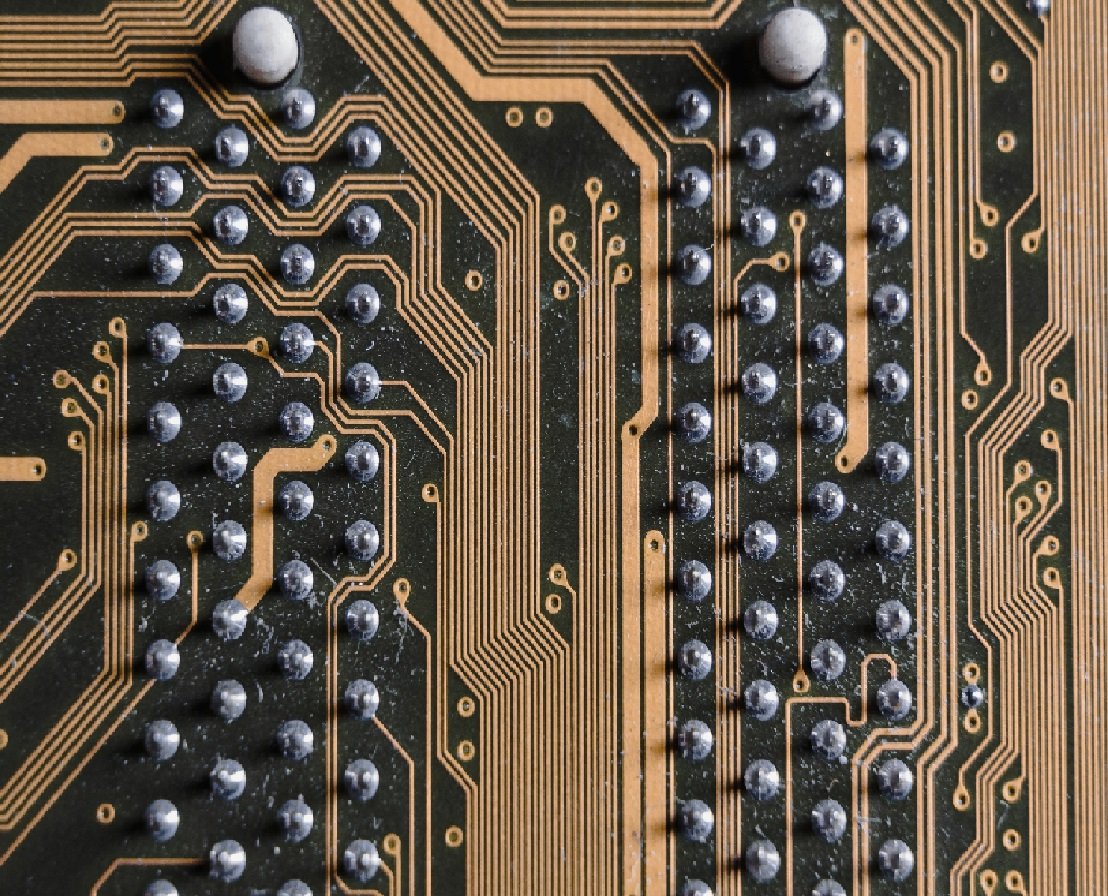

Introduction: Printed Circuit Boards (PCBs) are an essential component of modern electronics, acting as a base for interconnecting electronic components. While there are professional PCB manufacturing services available, many DIY enthusiasts and hobbyists prefer to create their own PCBs at home. In this guide, we will explore the step-by-step process of creating DIY home printed circuit boards, including the necessary materials, techniques, and tips for success. 1. Understanding the Basics of PCB Design: Before diving into the PCB fabrication process, it's important to have a solid understanding of PCB design. Familiarize yourself with the basic concepts, including component placement, routing, and signal integrity. Design software such as Eagle, KiCad, or EasyEDA can help you create your PCB layout efficiently. 2. Gathering the Necessary Materials: To create your own PCB at home, you'll need a few essential materials. These include: - Copper Clad Board: A copper clad board acts as the base material for your PCB. It's a flat board covered with a layer of copper on one or both sides. - Etching Solution: An etching solution, such as ferric chloride or ammonium persulfate, is used to remove unwanted copper from the board during the etching process. - Resist: A resist material such as photoresist or toner transfer paper is used to protect the areas of the PCB where copper traces should remain. - PCB Drill Bits: High-speed drill bits are necessary for drilling holes for component placement on the board. - Soldering Iron and Solder: These will be used to solder the electronic components onto the finished PCB. 3. Transferring the Design onto the PCB: There are various methods to transfer the PCB design onto the copper clad board. The most common methods include: - Toner Transfer Method: This involves printing your PCB design onto a special transfer paper using a laser printer and then transferring the toner onto the copper surface using heat. - Photoresist Method: In this method, a light-sensitive photoresist is applied to the copper surface. The PCB design is then exposed onto the photoresist using a UV light source. 4. Etching the PCB: Once the design is transferred onto the copper surface, it's time to etch the board. Follow the instructions provided with your chosen etching solution carefully. Typically, this involves immersing the board in the etching solution until all unwanted copper is removed, leaving only the desired copper traces intact. 5. Drilling Holes and Finalizing the PCB: After etching, drill holes into the PCB using the appropriate drill bits. These holes will allow for component placement and soldering. Ensure that the hole sizes match the component leads. Finally, clean the PCB to remove any residues from the etching process and make any necessary touch-ups before starting the soldering process. 6. Soldering the Components: With the PCB ready, it's time to solder the electronic components onto the board. Carefully follow the component placement and soldering instructions from your circuit design. Ensure proper solder joints and connections for optimal functionality. Conclusion: Creating your own DIY home printed circuit boards can be a rewarding experience for electronics enthusiasts. By following the steps outlined in this guide and using the appropriate materials and techniques, you can successfully fabricate your own custom PCBs from the comfort of your home. Remember to practice caution and precision throughout the process for the best results. Happy PCB making! For a different angle, consider what the following has to say. http://www.svop.org to Get more information at http://www.mimidate.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :