Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

A DIY Guide to Surface Mount Technology (SMT) Electronics for Your Home

Category : | Sub Category : Posted on 2023-10-30 21:24:53

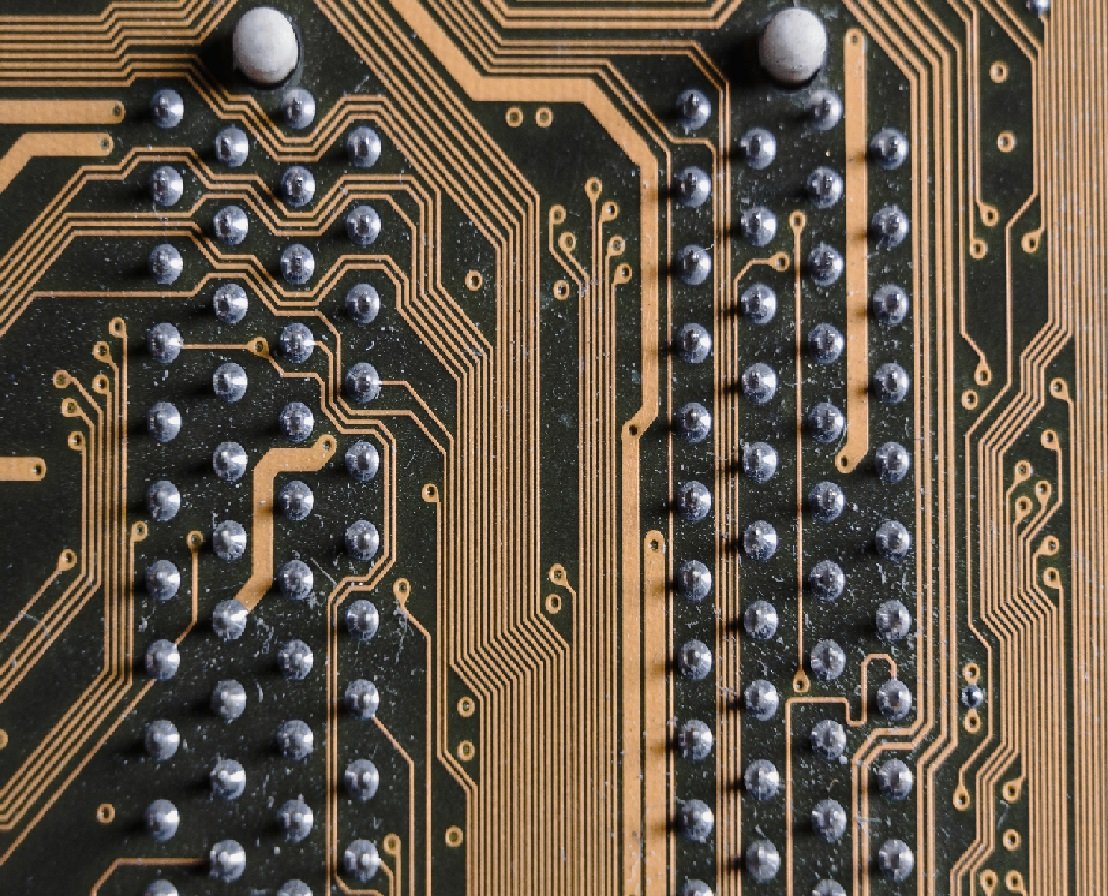

Introduction: With the advancement of technology, surface mount technology (SMT) has become the industry standard for electronics manufacturing. However, SMT is not limited to factories and commercial applications. In fact, you can incorporate SMT electronics into your home projects with a little knowledge and the right tools. In this blog post, we will guide you through the process of DIY SMT electronics for your home, making your projects more efficient and professional-looking. What is Surface Mount Technology (SMT)? Surface mount technology (SMT) refers to the method of soldering electronic components directly onto the surface of a printed circuit board (PCB), as opposed to the traditional through-hole method. SMT components are smaller, lighter, and more suitable for high-density circuit designs. Benefits of DIY SMT Electronics for Your Home: 1. Miniaturization: SMT components are much smaller than through-hole components, allowing you to design compact and space-saving circuits. This is particularly useful for projects with size constraints, such as wearable technology or home automation systems. 2. Efficiency: SMT electronics offer better electrical performance, signal integrity, and high-speed capabilities. By using SMT components in your home projects, you can achieve improved efficiency, durability, and functionality. 3. Cost-effectiveness: SMT components are mass-produced, making them cheaper than through-hole components on a per-unit basis. By using DIY SMT electronics, you can save money without compromising quality. Getting Started with DIY SMT Electronics: 1. Soldering Tools: To get started with DIY SMT electronics, you'll need some basic tools such as a soldering iron with a fine tip, solder wire, flux, solder paste, tweezers, and a magnifying glass or microscope for precision work. 2. Components: Choose SMT components for your project based on their form factor and specifications. You can find a wide range of SMT components online, including resistors, capacitors, integrated circuits (ICs), LEDs, and more. It's important to match the component sizes with your PCB design. 3. PCB Design: Design your PCB layout using software like Eagle, KiCad, or Altium Designer. Ensure that your PCB design follows the specifications provided by the component datasheets. Place the SMT components on the PCB with care, leaving appropriate clearance and maintaining a good layout for better heat dissipation. 4. Soldering Techniques: Soldering SMT components requires precision and practice. Use solder paste to apply a small amount of paste to the PCB pads. Carefully place the components on the paste using tweezers. Then, heat the solder paste with a soldering iron to melt the solder and create a strong electrical connection. 5. Inspection: Once the soldering process is complete, inspect your solder joints under a magnifying glass or microscope to ensure proper connections and avoid any solder bridges or dry joints. Use a multimeter to measure electrical continuity and check for any shorts or open circuits. Conclusion: Integrating surface mount technology (SMT) electronics into your DIY home projects can elevate their performance, efficiency, and aesthetics. With the right tools, components, and soldering techniques, you can create professional-looking circuits just like those found in commercial electronics. Start exploring the world of SMT electronics and take your DIY projects to the next level! Remember to always prioritize safety while working with electronic components and practice good soldering techniques. Visit the following website http://www.svop.org Explore expert opinions in http://www.mimidate.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :