Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Mastering Soldering Techniques: A Guide for DJs by DJ_Acid_UK

Category : | Sub Category : Posted on 2023-10-30 21:24:53

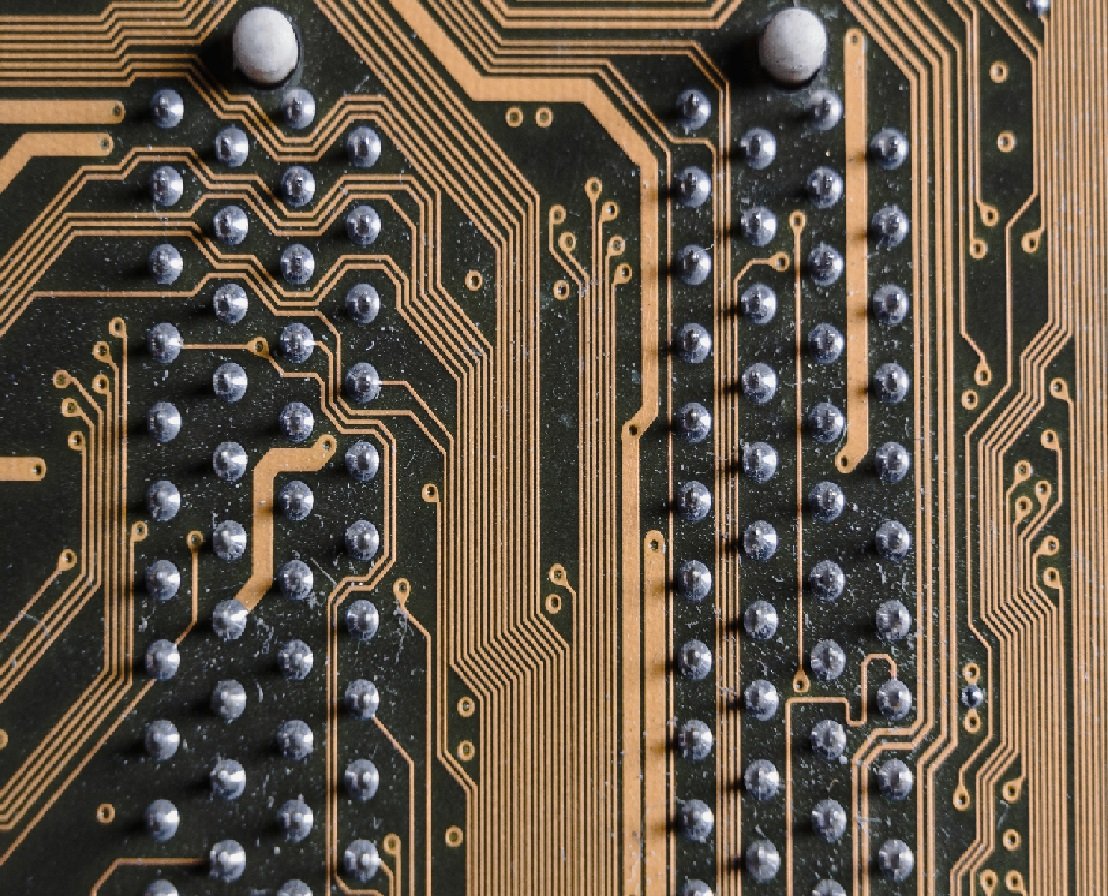

Introduction: As a DJ, your equipment is the lifeblood of your craft. Whether you're tweaking gear or building your own custom devices, understanding soldering techniques is essential. In this blog post, we'll dive into the world of soldering with the help of DJ_Acid_UK, a seasoned DJ and electronics enthusiast. Get ready to level up your soldering skills and take your DJing game to new heights! 1. Choosing the Right Soldering Iron: Before you can become a soldering pro, you need to invest in a good quality soldering iron. DJ_Acid_UK recommends choosing a temperature-regulated iron with a small and fine-tipped design, as it allows for precise soldering in tight spaces. Additionally, be sure to opt for a soldering station that gives you control over temperature settings, as this is crucial for different soldering applications. 2. Preparing Your Workspace: A tidy and organized workspace is key to successful soldering. DJ_Acid_UK suggests creating a dedicated area for your soldering station, equipped with a heat-resistant mat, an adjustable armature for holding your workpiece, and good lighting. Keeping your workspace clean and organized will not only enhance your soldering precision but also prevent accidental damage to your equipment. 3. Choosing the Right Solder and Flux: Selecting the appropriate solder and flux is essential for achieving reliable and durable solder joints. DJ_Acid_UK recommends using a solder with a low gauge, typically 0.7mm or 0.8mm, as it provides adequate heat transfer while minimizing the risk of overheating delicate components. When it comes to flux, choose a rosin-based flux for general-purpose soldering or a no-clean flux for surface-mount components. 4. Proper Cleaning and Tinning: Before you start soldering, it's important to clean the tip of your soldering iron and apply a thin coat of fresh solder, known as tinning. DJ_Acid_UK explains that this process removes any oxidation or residue on the iron, ensuring optimal heat transfer and a clean solder joint. Remember to periodically clean and re-tin your soldering iron during longer soldering sessions for consistent performance. 5. Mastering Soldering Techniques: DJ_Acid_UK shares his expertise on essential soldering techniques for DJs: - Through-Hole Soldering: This technique is commonly used for soldering components onto the surface of a circuit board. DJ_Acid_UK advises placing the component through the holes on the board, applying heat to both the pad and lead, and then feeding solder to form a clean and strong connection. - SMD Soldering: Surface-Mount Device (SMD) soldering is frequently encountered when working with modern DJ equipment. DJ_Acid_UK recommends using a fine-tipped soldering iron and applying a small amount of solder paste or flux to the component's pads. Next, heat the solder and pad simultaneously, allowing the solder to flow onto the pad and create a reliable connection. 6. Practice Makes Perfect: DJ_Acid_UK emphasizes the importance of practice in mastering soldering techniques. Start with simple projects or kits to gain confidence and gradually work your way up to more complex projects. Don't be disheartened by initial mistakes; with time and practice, you'll become proficient in soldering and be able to handle more advanced DJ equipment modifications. Conclusion: By mastering soldering techniques, DJs can comfortably tackle gear modifications or build custom devices, enabling them to shape their sound and bring their creativity to life. Follow the expert advice of DJ_Acid_UK, invest in quality tools, and practice consistently. With perseverance and attention to detail, you'll soon be soldering like a pro, opening up new possibilities in your DJing journey. For a deeper dive, visit: http://www.loveacid.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :