Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Rise of Drones with Printed Circuit Boards

Category : | Sub Category : Posted on 2023-10-30 21:24:53

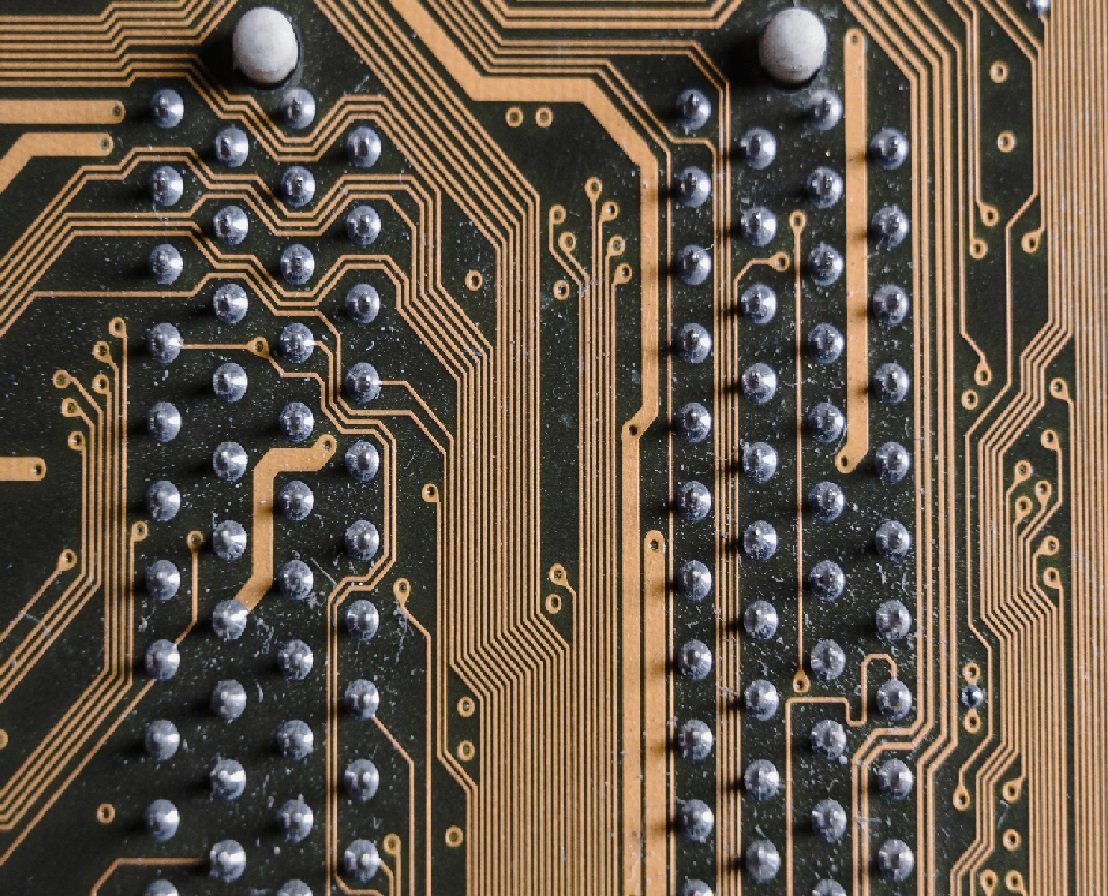

Introduction: In recent years, drones have taken the world by storm, revolutionizing various industries such as agriculture, filmmaking, and delivery services. As technology continues to advance at a rapid pace, one crucial component that has played a significant role in the evolution of drones is printed circuit boards (PCBs). In this blog post, we will explore the impact of PCBs on drone technology and how they have transformed these unmanned aerial vehicles into powerful tools for a wide range of applications. What are Printed Circuit Boards (PCBs)? Printed circuit boards, often referred to as PCBs, are essential components of modern electronic devices. A PCB is a thin board made of a non-conductive material, usually fiberglass or composite epoxy, with conductive paths etched into it. These paths, known as traces, connect various electronic components, such as microchips, sensors, and connectors, on the board. Benefits of PCBs in Drones: 1. Compact and Lightweight Design: One of the key advantages of using PCBs in drones is their ability to create compact and lightweight designs. PCBs allow for the integration of multiple electronic components into a single board, reducing the overall size and weight of the drone. This, in turn, improves flight efficiency and maneuverability. 2. Improved Signal Integrity: PCBs ensure proper signal flow between different components by minimizing electrical noise. This is crucial for the accurate functioning of drones, especially when transmitting data from sensors, cameras, or GPS systems. By reducing the interference caused by signal degradation, PCBs enable drones to perform more reliably and accurately. 3. Efficient Power Distribution: With the increasing complexity of drone components, power management becomes a critical factor. PCBs allow for the efficient distribution of power across the drone, ensuring that each component receives the right amount of electricity. This not only enhances the performance but also prolongs the battery life of the drone. 4. Customization and Flexibility: PCBs offer a high level of customization and flexibility, which is advantageous for drone manufacturers. Designers can easily modify the layout, connections, and size of PCBs to suit specific drone requirements. This adaptability allows for rapid development and iterations, leading to improved functionality and performance. 5. Streamlined Manufacturing Process: PCBs enable efficient and cost-effective manufacturing of drones. They can be mass-produced using automated assembly processes, reducing production time and costs. The streamlined manufacturing process also ensures consistency in the quality and performance of the drones. Conclusion: Printed circuit boards have significantly contributed to the evolution of drone technology, making them more compact, reliable, and versatile. Through their ability to integrate and connect various electronic components, PCBs have paved the way for advancements in drone design, increasing their overall performance and capabilities. As the demand for drones continues to rise across different industries, it is evident that the role of PCBs will remain critical in shaping the future of unmanned aerial vehicles. For an extensive perspective, read http://www.jetiify.com To understand this better, read http://www.s6s.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :