Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Exploring the Latest Trends: Through-Hole Technology in Electronics Manufacturing in Egypt's Capital, Cairo

Category : | Sub Category : Posted on 2023-10-30 21:24:53

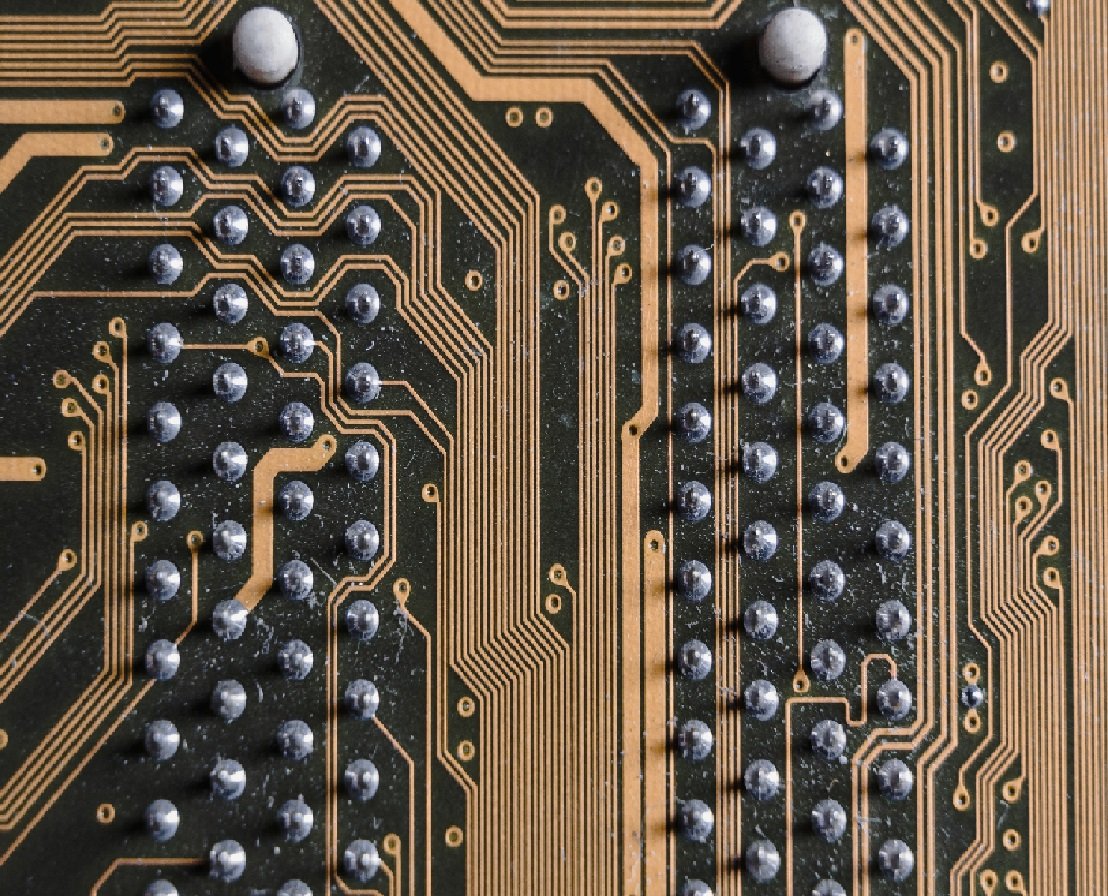

In today's fast-paced world, technological advancements are inevitable. One of the key areas where innovation plays a crucial role is in electronics manufacturing. Among the various methods used in this industry, through-hole technology has emerged as a reliable and efficient approach. In Egypt's bustling capital, Cairo, through-hole technology has gained significant popularity in recent years. This method involves mounting electronic components onto a printed circuit board (PCB) by inserting their leads into holes on the board and then soldering them onto copper traces on the other side. So, why has through-hole technology become so appealing in Cairo's electronics manufacturing sector? Let's explore some of the reasons behind its widespread implementation. 1. Durability and Reliability: Through-hole technology provides excellent mechanical stability compared to its surface-mounted counterpart. The soldered connections created through this method are resistant to vibrations and shocks, making them ideal for applications that demand enhanced durability, such as aerospace and automotive industries. 2. Ease of Repair and Replacement: Another advantage of through-hole components is their ease of repair and replacement. When a component malfunctions, it can be desoldered and replaced individually without affecting other parts on the PCB. This feature is particularly advantageous in industries where maintenance and repair are critical, minimizing downtime and costs. 3. Enhanced Heat Dissipation: Many electronic systems generate significant amounts of heat during operation. Through-hole technology allows for efficient heat dissipation due to the larger mass of the components and the capability to use heat sinks or thermal pads. This makes it highly suitable for applications where thermal management is essential, such as power electronics. 4. Suitable for High Current Applications: Through-hole technology is well-suited for high-current applications since the holes can accommodate larger wire gauges. This allows for the efficient flow of current, reducing the risk of overheating and improving overall performance and efficiency. 5. Compatibility with Legacy Designs: Despite its evolution, through-hole technology has been around for many decades. As a result, it is highly compatible with legacy designs that still populate various industries. In Cairo's electronics manufacturing scene, where many companies rely on established designs, through-hole technology provides an easy and cost-effective solution for incorporating new components into existing systems. With Cairo being a hub for technology and innovation, it comes as no surprise that through-hole technology has found an enthusiastic following among electronics manufacturers. The method's reliability, durability, ease of repair, heat dissipation capabilities, and compatibility make it an attractive choice for industries seeking to leverage technology to stay ahead in the competitive market. In conclusion, through-hole technology has become an integral part of the electronics manufacturing landscape in Cairo, Egypt. Its numerous advantages, including durability, ease of repair, heat dissipation, high current applications, and compatibility with legacy designs, make it an indispensable choice for a wide range of industries. As this vibrant city continues to embrace technological advancements, through-hole technology will undoubtedly remain a significant player in shaping the future of electronics manufacturing. Find expert opinions in http://www.egyptwn.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :