Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

A Complete Guide to Electronics Design and Failure Analysis in Embedded Systems

Category : | Sub Category : Posted on 2023-10-30 21:24:53

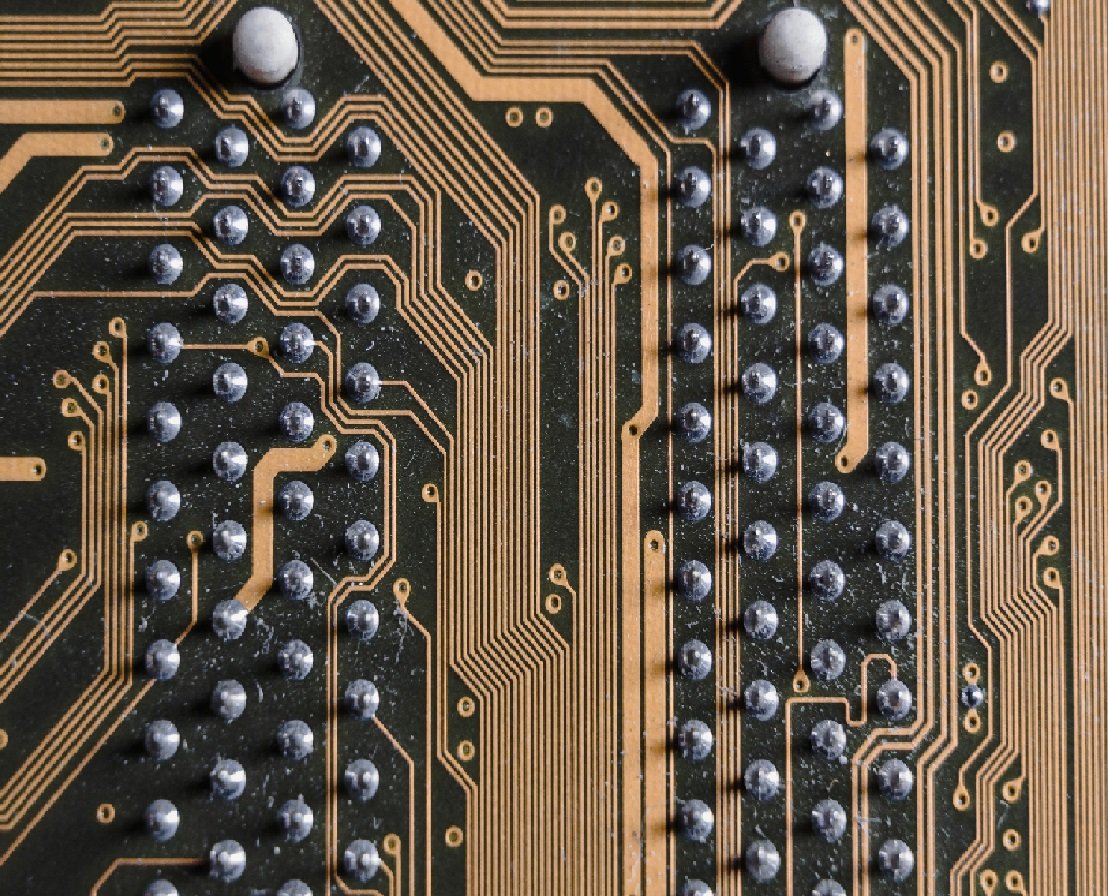

Introduction In today's technology-driven world, electronics are an integral part of our everyday lives. From smartphones and laptops to smart home devices and automotive systems, electronics play a crucial role in our interconnected world. One key aspect of electronics design and development is the analysis of failures that can occur in embedded systems. In this blog post, we will explore the world of electronics design and delve into the importance of failure analysis in embedded systems. Understanding Electronics Design Electronics design involves the process of creating circuits or systems that perform a desired function using various electronic components such as resistors, capacitors, transistors, and integrated circuits (ICs). It encompasses different stages, including concept design, schematic design, PCB layout, routing, and manufacturing. Embedded Systems and Their Significance Embedded systems refer to computer systems designed to perform specific tasks with dedicated functions. These systems are typically integrated into larger devices or equipment to control and monitor their operation. Examples of embedded systems can be found in household appliances, industrial equipment, healthcare devices, and even automobiles. Electronics Failure Analysis: Importance and Benefits Failure analysis is a critical aspect of electronics design, as it helps engineers and designers identify, diagnose, and troubleshoot problems that occur within embedded systems. By conducting a thorough analysis, engineers can pinpoint the causes of failures and develop effective solutions, ensuring the reliability and performance of the final product. Here are the key benefits of performing failure analysis in embedded systems: 1. Improved reliability: Failure analysis helps identify weak points in the system design, component selection, or manufacturing process. By addressing these issues, engineers can improve the overall reliability and longevity of the system. 2. Cost-effectiveness: Identifying and resolving potential issues during the design phase can save significant costs that might arise from repair or replacement of faulty components later in the product lifecycle. 3. Enhanced performance: Failure analysis provides valuable insights into the behavior of the system, allowing engineers to optimize its performance. By understanding the root cause of failures, developers can fine-tune their design and achieve superior functionality. Methods and Tools for Failure Analysis Several techniques and tools are available for performing failure analysis in embedded systems. These include: 1. Visual inspection: This initial step involves a close examination of the system's physical components for obvious signs of damage or defects. 2. Electrical testing: Electrical testing helps detect any anomalies in the circuitry, such as short circuits, open circuits, or incorrect voltage levels. 3. Thermographic analysis: By utilizing infrared thermography, engineers can identify areas of excessive heat, possibly caused by component failures or electrical overloads. 4. X-ray inspection: X-ray analysis allows designers to examine the internal structure of a device without disassembling it, helping to locate faults such as cracked solder joints or component misalignment. 5. Reverse engineering: Sometimes, failure analysis involves reconstructing the system's design from scratch to understand its workings better. This method is particularly useful when dealing with legacy systems or complex circuitry. Conclusion Electronics design and failure analysis in embedded systems are essential for creating reliable, high-performance electronic products. By investing time and effort in analyzing failures, engineers can identify the root causes and develop solid solutions. This ensures that embedded systems meet the required standards of performance, reliability, and longevity. In our evolving technological landscape, failure analysis remains a crucial aspect of electronics design, enabling the development of innovative and efficient products.

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :