Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Exploring the World of Electronics Design and Embedded Systems Manufacturing

Category : | Sub Category : Posted on 2023-10-30 21:24:53

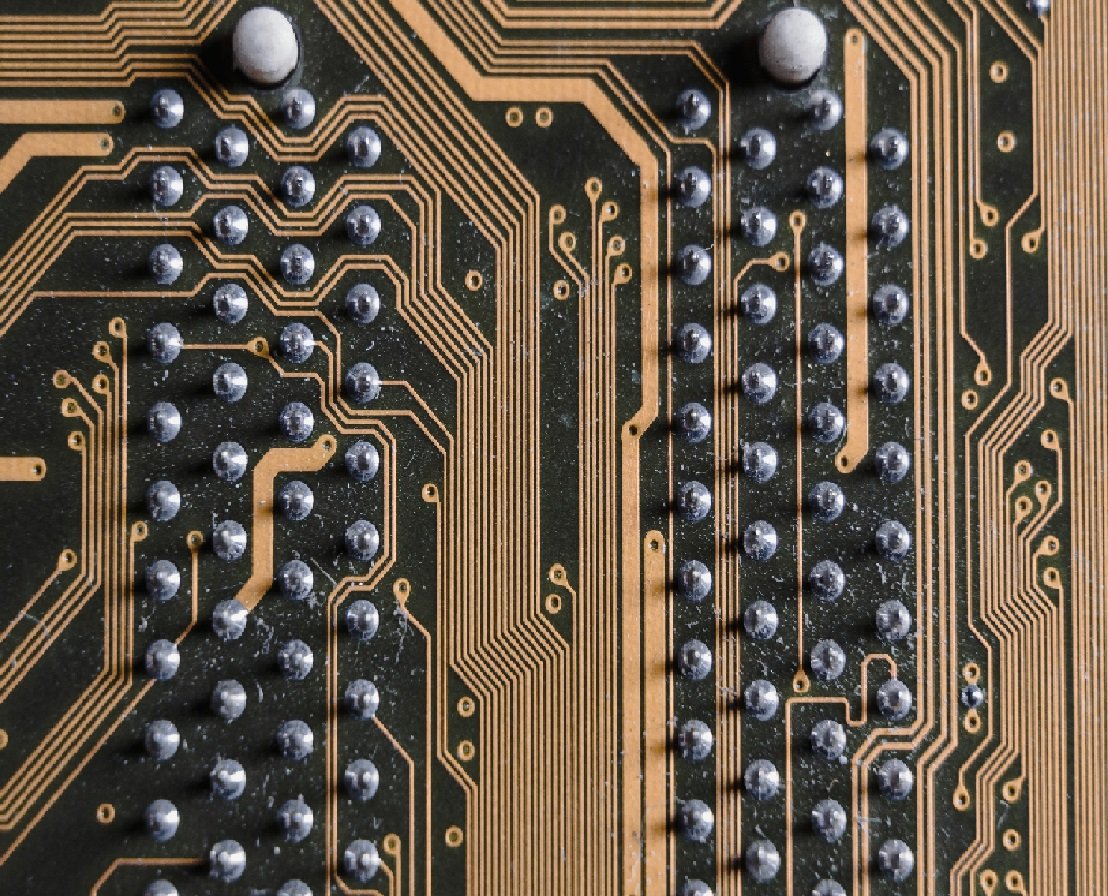

Introduction: In this fast-paced technological era, electronics design and embedded systems manufacturing have become integral to our daily lives. From our smartphones to our home appliances, electronics have revolutionized the way we live and communicate. In this blog post, we will delve deeper into the world of electronics design and explore its intricate connection with embedded systems manufacturing. 1. The Basics of Electronics Design: Electronics design is the process of creating electronic circuits and systems that meet specific requirements. It involves a combination of scientific principles, engineering expertise, and creativity to design circuits that can perform desired functions efficiently. These circuits can range from simple to highly complex, depending on the intended application. 2. Designing Embedded Systems: Embedded systems are electronic systems that are embedded within other devices to control their functionality. They are typically designed to perform specific tasks and operate within a predefined set of parameters. Embedded systems can be found in a wide range of devices, including medical equipment, automotive systems, and consumer electronics. 3. Challenges in Electronics Design: Electronics design comes with its fair share of challenges. Engineers need to consider factors like power consumption, size constraints, cost-efficiency, and reliability while designing electronic circuits. They also need to keep up with rapid technological advancements and industry standards to ensure that their designs are up to date. 4. The Role of Electronics Manufacturing: Once the electronics design process is complete, the next step is manufacturing. Electronics manufacturing involves the mass production of electronic components and the assembly of these components into full-fledged systems. It requires specialized facilities, equipment, and expertise to ensure that the final product meets quality standards. 5. Types of Electronics Manufacturing: Electronics manufacturing can be broadly classified into two categories: printed circuit board (PCB) assembly and system assembly. PCB assembly involves mounting electronic components onto a PCB, while system assembly involves integrating PCBs, wiring, interfaces, and other components into a final system. Both processes require precision and attention to detail. 6. Challenges in Electronics Manufacturing: Electronics manufacturing brings its own set of challenges. Quality control, component sourcing, supply chain management, and meeting production schedules are some of the primary challenges manufacturers face. Additionally, as technology evolves rapidly, manufacturers must adapt and upgrade their equipment and processes to stay competitive. 7. The Future of Electronics Design and Manufacturing: The field of electronics design and embedded systems manufacturing is continuously evolving. Advancements such as miniaturization, Internet of Things (IoT), and artificial intelligence are shaping the future of electronic devices. With the increasing demand for smart and connected products, electronics design and manufacturing will play a crucial role in driving innovation and improving the quality of life for people worldwide. Conclusion: Electronics design and embedded systems manufacturing are vital components of today's technological landscape. From concept to production, these processes involve intricate planning, creativity, and attention to detail. As technology progresses, the world of electronics design and manufacturing will continue to innovate, providing us with more efficient and advanced electronic devices that simplify and enhance our lives.

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :