Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Future of Industrial Robotics: Revolutionizing Electronics Design and Embedded Systems

Category : | Sub Category : Posted on 2023-10-30 21:24:53

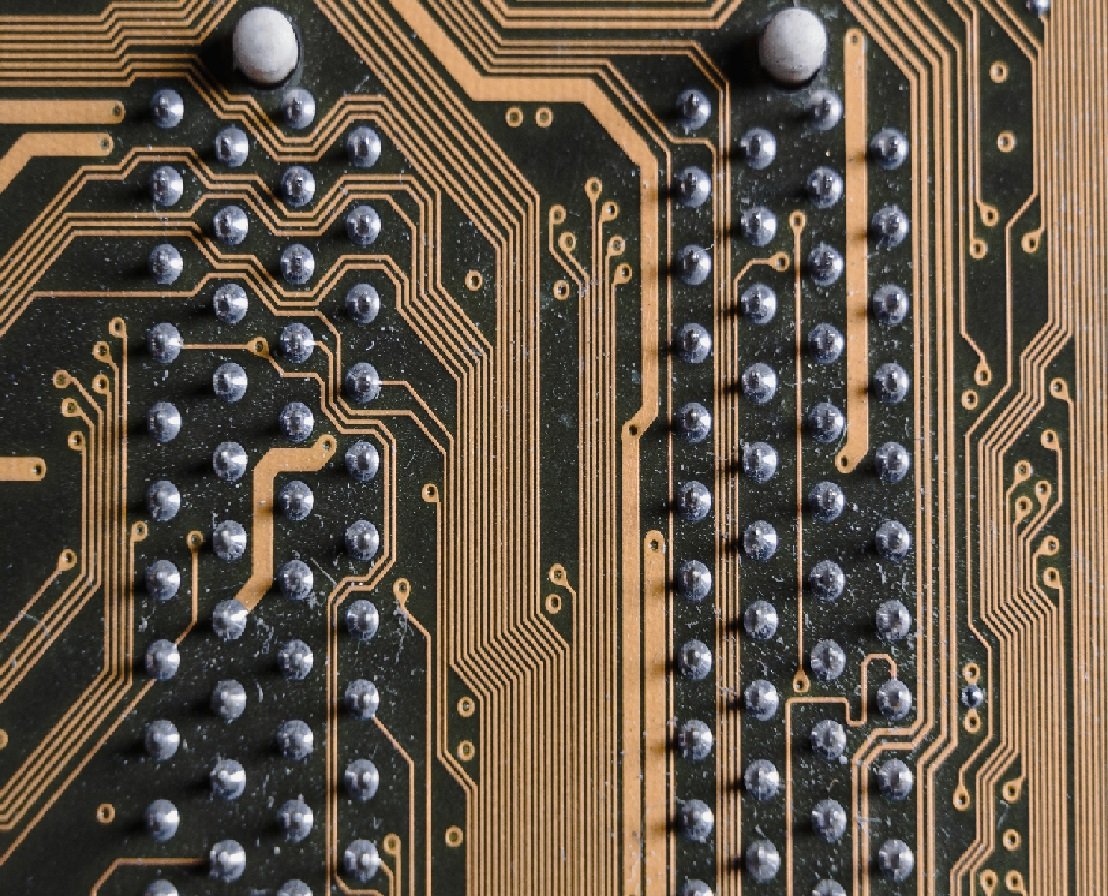

Introduction The world of electronics design and embedded systems has been significantly transformed with the rise of industrial robotics. These smart machines have revolutionized manufacturing processes by streamlining production lines, increasing efficiency, and improving overall product quality. In this blog post, we will explore how industrial robotics is shaping the future of electronics design and embedded systems. 1. Increased Automation One of the greatest contributions of industrial robotics to electronics design and embedded systems is increased automation. These robots have the ability to perform intricate tasks with precision, speed, and accuracy, reducing human error and minimizing production time. By automating processes such as PCB assembly, component testing, and circuit board prototyping, industrial robots have enhanced the efficiency and reliability of electronics manufacturing. 2. Enhanced Productivity With the integration of artificial intelligence and machine learning algorithms, industrial robots are becoming increasingly autonomous. They can adapt to different production scenarios, optimize production flows, and even detect and resolve issues proactively. The continuous monitoring and analysis of data enable these robots to identify bottlenecks, improve cycle times, and maximize resource utilization. As a result, electronics design and embedded systems are becoming more productive, leading to higher output and lower costs. 3. Improved Quality Control Ensuring the quality of electronic products is crucial in meeting customer expectations. Industrial robotics has significantly improved the quality control processes in electronics design and embedded systems. These robots perform detailed inspections using advanced vision systems, ensuring that products meet strict quality standards and specifications. Additionally, robots can perform complex and repetitive tests consistently, eliminating human error and enhancing the overall reliability of the final product. 4. Flexibility and Customization Flexibility and customization have become essential elements in today's electronics market. Industrial robots are equipped with advanced programming capabilities, allowing manufacturers to easily reconfigure their production lines to accommodate different product designs and variations. This flexibility enables companies to swiftly adapt to changes in consumer demands, efficiently producing customized electronics without compromising time or quality. 5. Safety and Ergonomics Industrial robotics not only enhances productivity but also contributes to the improvement of working conditions for employees. Robots can handle hazardous and repetitive tasks that pose risks to human workers, reducing the potential for workplace accidents and injuries. With industrial robots taking over tasks that demand physical exertion, employees can be allocated to higher-value tasks such as programming, troubleshooting, and quality control, promoting their professional development within the industry. Conclusion Industrial robotics has undoubtedly had a profound impact on the field of electronics design and embedded systems. The integration of intelligent machines into manufacturing processes has led to increased automation, enhanced productivity, improved quality control, greater flexibility, and improved workplace safety. As advancements in robotics and AI continue to evolve, it is clear that the future of electronics manufacturing will heavily rely on these automated systems. With their ability to streamline production processes and meet the growing demands of customization, industrial robots are set to shape a brighter future for electronics design and embedded systems. Uncover valuable insights in http://www.pxrobotics.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :