Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Integration of Electronics Design and Embedded Systems in Metals Manufacturing

Category : | Sub Category : Posted on 2025-11-03 22:25:23

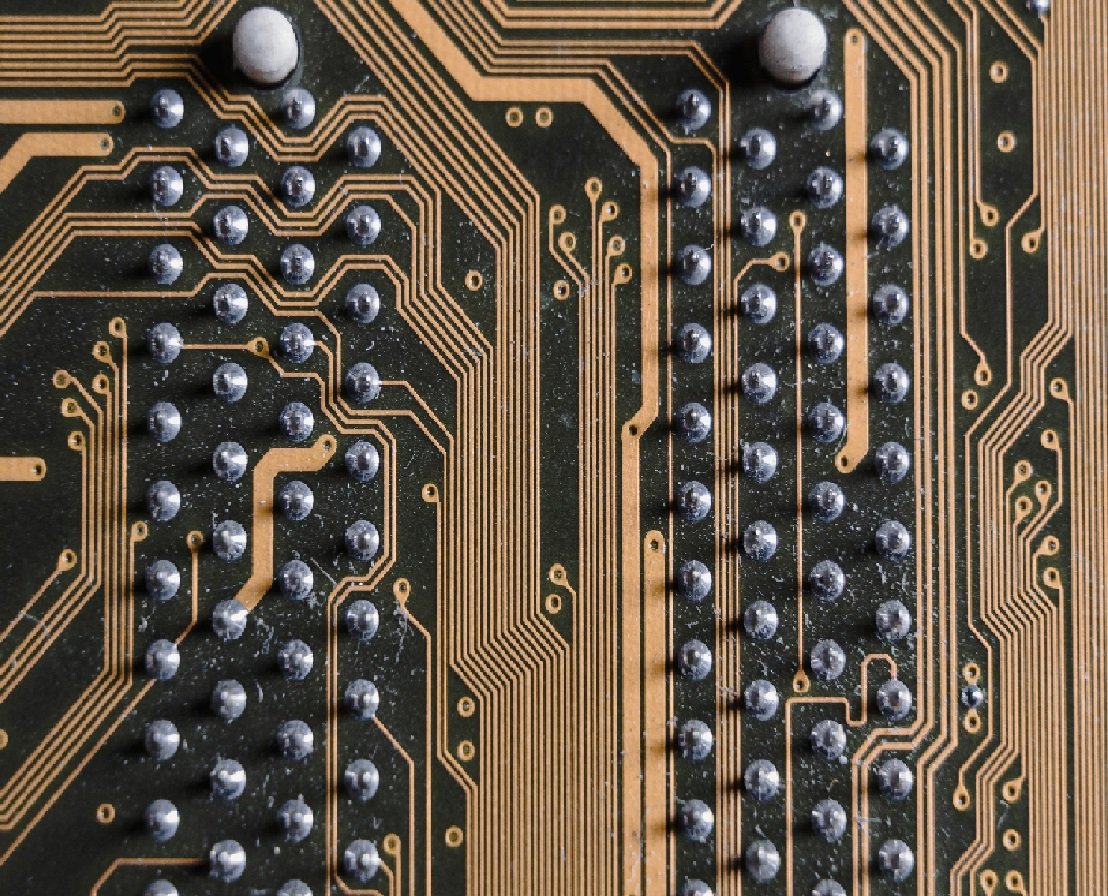

In the world of metals manufacturing, technology plays a crucial role in ensuring efficiency and precision. The integration of electronics design and embedded systems has revolutionized the way metal products are fabricated, processed, and monitored. This advanced technology has significantly improved the quality of metal products while streamlining production processes. Electronics design involves creating electronic circuits, components, and systems that are used in various applications. In metals manufacturing, electronics design plays a vital role in the automation of processes such as metal cutting, welding, and bending. These electronic systems control machinery and equipment, ensuring accuracy and consistency in metal fabrication. Embedded systems, on the other hand, are specialized computing systems that are designed to perform specific tasks within a larger system. In metals manufacturing, embedded systems are integrated into machinery and equipment to monitor and control different parameters such as temperature, pressure, and speed. These systems ensure that the manufacturing process runs smoothly and efficiently, leading to higher productivity and reduced downtime. The integration of electronics design and embedded systems in metals manufacturing has led to several advancements. For example, the use of sensors and actuators in embedded systems allows for real-time monitoring of the production process, enabling operators to make quick adjustments to optimize efficiency and quality. Additionally, the use of programmable logic controllers (PLCs) in electronics design has automated many manufacturing tasks, reducing the need for manual intervention and human error. Another significant benefit of integrating electronics design and embedded systems in metals manufacturing is the ability to collect and analyze data. By incorporating data acquisition systems into the production line, manufacturers can gather valuable information about process parameters, equipment performance, and product quality. This data can be used to identify trends, detect anomalies, and make informed decisions to improve overall operations. Furthermore, the integration of electronics design and embedded systems paves the way for the implementation of Industry 4.0 principles in metals manufacturing. Industry 4.0, also known as the fourth industrial revolution, focuses on the interconnectedness of devices, processes, and people through the use of advanced technology. By embracing Industry 4.0 concepts, metals manufacturers can achieve greater flexibility, customization, and efficiency in their operations. In conclusion, the integration of electronics design and embedded systems has brought significant benefits to metals manufacturing. From improving product quality and process efficiency to enabling real-time monitoring and data analysis, this advanced technology has transformed the way metal products are fabricated. As technology continues to evolve, we can expect further innovations that will drive the metals manufacturing industry towards greater competitiveness and sustainability. to Get more information at https://www.modernos.org for more https://www.gafam.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :