Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

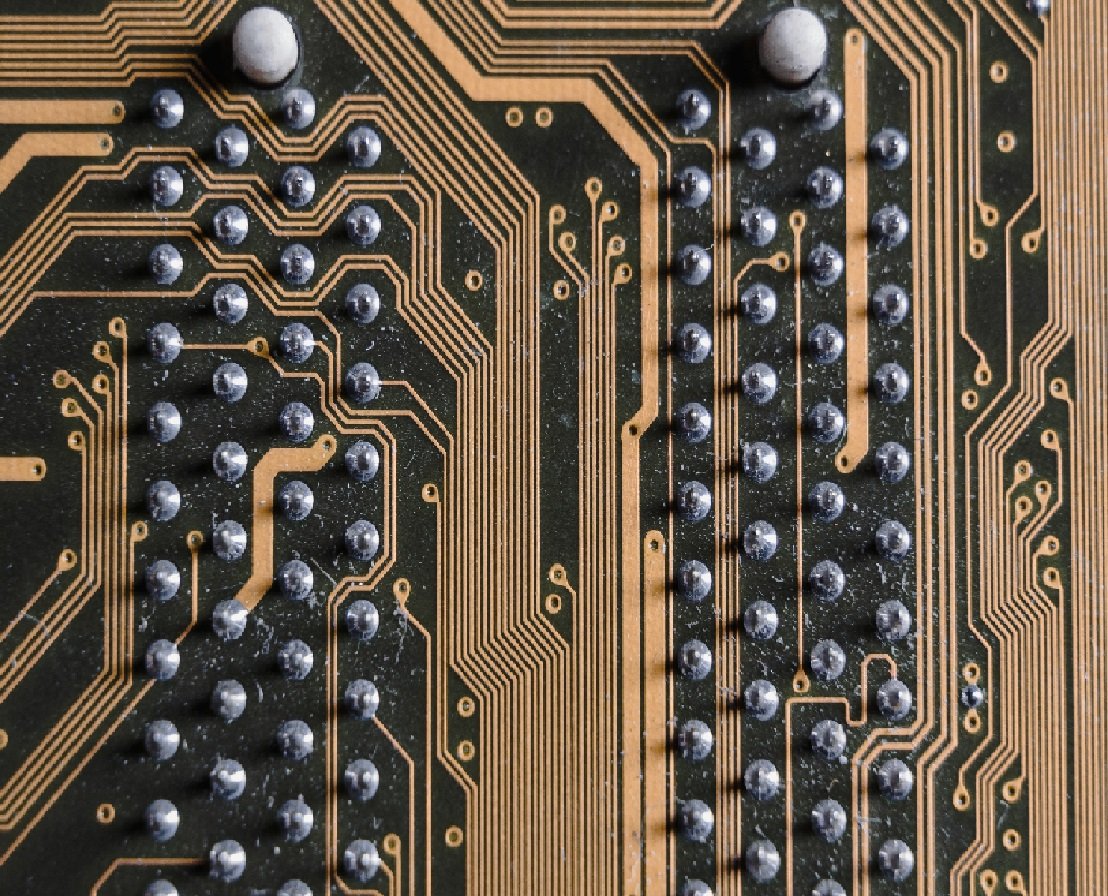

Mastering Soldering Techniques for Electronics Design and Embedded Systems

Category : | Sub Category : Posted on 2023-10-30 21:24:53

Introduction: Soldering is an essential skill for anyone involved in electronics design and embedded systems. Whether you are a beginner or an experienced professional, mastering soldering techniques is crucial to ensure reliable and high-quality connections in your electronic projects. In this blog post, we will explore some of the best practices and tips for successful soldering. 1. Choosing the Right Soldering Iron: The first step in achieving perfect soldering is selecting the right soldering iron. Consider factors like power, temperature control, and tip compatibility. A soldering iron with adjustable temperature settings can provide more control over the soldering process and prevent overheating delicate components. 2. Preparing Your Work Area: Maintaining a clean and organized work area is essential for efficient soldering. Make sure there is adequate lighting, good ventilation, and a fire-resistant surface for soldering. Keep all necessary tools and materials close at hand, including solder, flux, PCBs, and components. 3. Properly Prepping Components and PCBs: Before soldering, it's crucial to prepare the components and PCBs to ensure a strong and reliable connection. Start by cleaning the components and PCBs to remove any oxidation or contaminants. Use a small amount of flux on both the component leads and PCB pads to enhance solder flow and adhesion. 4. Understanding Solder Types: Choosing the right solder is crucial for successful soldering. There are several types of solder available, including lead-based and lead-free options. Lead-based solder is commonly used due to its lower melting point and better flow properties. However, if you're working with lead-free components, make sure to use a compatible solder. 5. Mastering Soldering Techniques: a. Tinning the Iron: Before starting to solder, it's essential to tin the soldering iron tip. Apply a small amount of solder to the iron's tip, ensuring complete coverage. This process helps improve heat transfer between the iron and the components. b. Heat Control: Controlling the application of heat is critical. Apply the heated soldering iron tip to the joint for a few seconds to allow the surfaces to reach the desired temperature. Then, gently apply solder to the joint, ensuring it flows smoothly and forms a shiny, concave fillet. c. Keeping it Clean: Clean the soldering iron tip frequently during the soldering process using a damp sponge or brass pad. This removes excess solder residue and prevents it from contaminating future joints. d. Avoiding Cold Joints: Cold joints occur when the solder has not properly melted and flowed onto the joint. To avoid cold joints, make sure to apply sufficient heat to the joint area and ensure proper wetting of the solder. 6. Safety Considerations: Soldering involves working with high temperatures and potentially hazardous fumes. Ensure you take necessary safety precautions, such as wearing safety goggles, avoiding loose clothing, and working in a well-ventilated area. Additionally, be cautious while handling the hot soldering iron, ensuring it is placed on a suitable stand when not in use. Conclusion: Mastering soldering techniques is fundamental for successful electronics design and embedded systems projects. By selecting the right soldering iron, preparing your work area, using the appropriate solder, and employing the correct techniques, you can achieve reliable and high-quality solder connections. Practice, patience, and continuous improvement are key to becoming proficient in soldering and ensuring the longevity of your electronic projects.

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :