Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Mastering the Art of Surface Mount Technology in Electronics Design and Embedded Systems

Category : | Sub Category : Posted on 2023-10-30 21:24:53

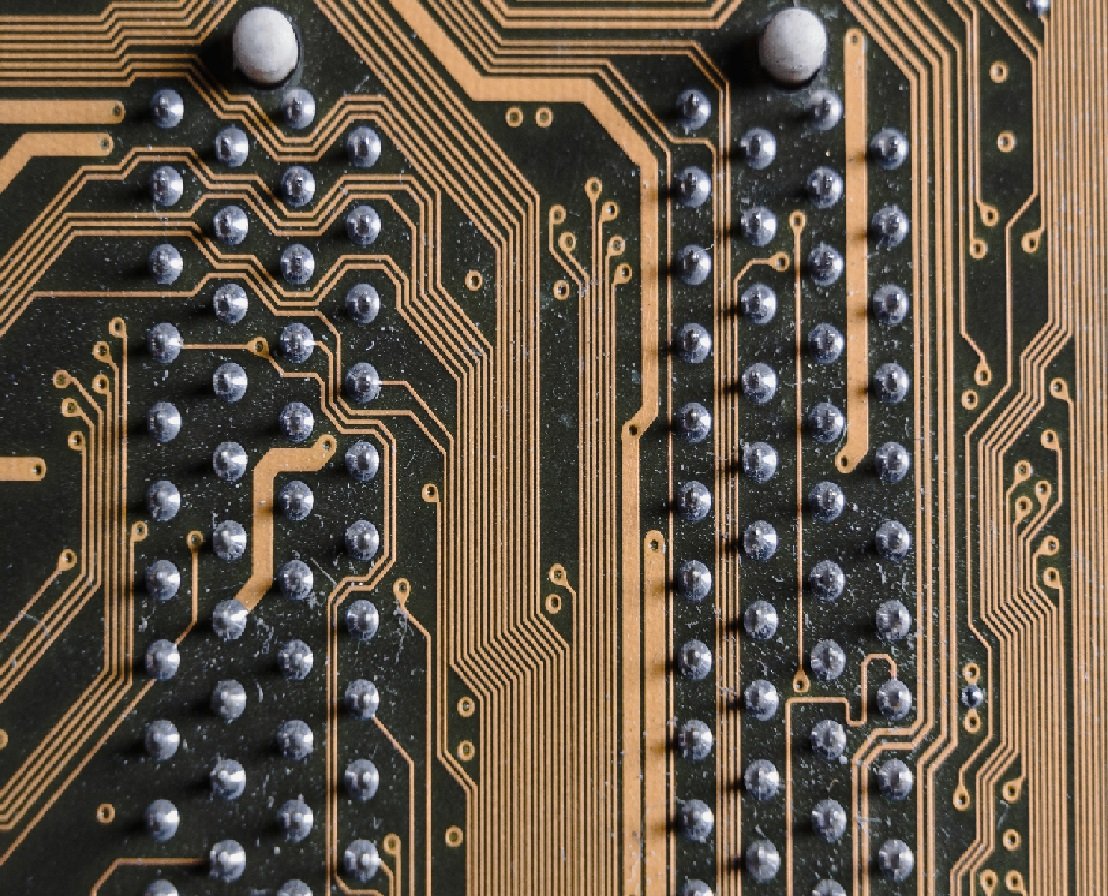

Introduction: In the world of electronics design and embedded systems, Surface Mount Technology (SMT) has become the go-to method for creating high-performance and miniaturized electronic devices. With the ability to densely pack components on a board, SMT offers improved efficiency, reduced size, and increased reliability. In this blog post, we will explore the fascinating world of SMT electronics, its advantages, challenges, and the key considerations for designing and implementing SMT-based systems. 1. Understanding Surface Mount Technology (SMT): Surface Mount Technology is a process that involves mounting electronic components directly onto the surface of a printed circuit board (PCB), as opposed to the through-hole method where components are inserted into drilled holes. SMT offers several advantages over through-hole technology, including smaller component sizes, increased component density, better electrical performance, and cost-effectiveness. 2. Advantages of Surface Mount Technology: a. Size Reduction: SMT components are significantly smaller than through-hole components, allowing for the design and production of miniaturized electronic devices. b. Improved Electrical Performance: SMT components have shorter lead lengths compared to through-hole components, leading to reduced parasitic capacitance and inductance. This results in improved high-frequency performance, reduced noise, and better signal integrity. c. Higher Component Density: With SMT, components can be densely packed on both sides of the PCB, maximizing the use of available space. d. Automated Assembly: SMT is compatible with automated assembly processes, enabling faster and cheaper production compared to manual through-hole soldering. 3. Challenges in Surface Mount Technology: While SMT offers numerous benefits, it also presents unique challenges that need to be overcome to ensure robust and reliable designs. Some of the key challenges include: a. Component Size and Handling: Working with small SMT components requires specialized tools and techniques. Precise placement, alignment, and rework can be challenging for engineers who are new to SMT. b. Thermal Management: The compact size of SMT components and their proximity to each other can result in increased heat generation. Proper thermal management techniques, such as heat sinks and careful PCB layout, are critical to ensure the longevity and performance of SMT-based systems. c. Soldering Techniques: SMT components are typically soldered using reflow soldering techniques, which require precise temperature control and solder paste application. Inadequate soldering can lead to poor electrical connections, reliability issues, and premature failure. 4. Design Considerations for SMT Electronics: To optimize the performance and reliability of SMT-based systems, designers need to consider the following aspects: a. Component Selection: Choosing the right components with appropriate ratings, lead pitch, and reliability specifications is essential for successful SMT implementation. b. PCB Layout: Proper PCB layout is crucial to ensure signal integrity, thermal management, and the avoidance of soldering issues. Techniques such as proper component placement, trace routing, and ground plane design should be carefully considered. c. Design for Manufacturability (DFM): Collaborating with manufacturers during the design phase helps incorporate their expertise and ensure that the design is manufacturable, reducing the risk of errors and lowering production costs. Conclusion: Surface Mount Technology has revolutionized the world of electronics design and embedded systems, allowing for smaller, more efficient, and affordable devices. Mastering the art of SMT requires a deep understanding of its advantages, challenges, and design considerations. By embracing SMT, designers can unlock a new realm of possibilities in electronics innovation, enabling the development of cutting-edge products that shape the future of technology.

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :