Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

The Evolution of Electronic Devices: From Registration to Printed Circuit Boards

Category : | Sub Category : Posted on 2023-10-30 21:24:53

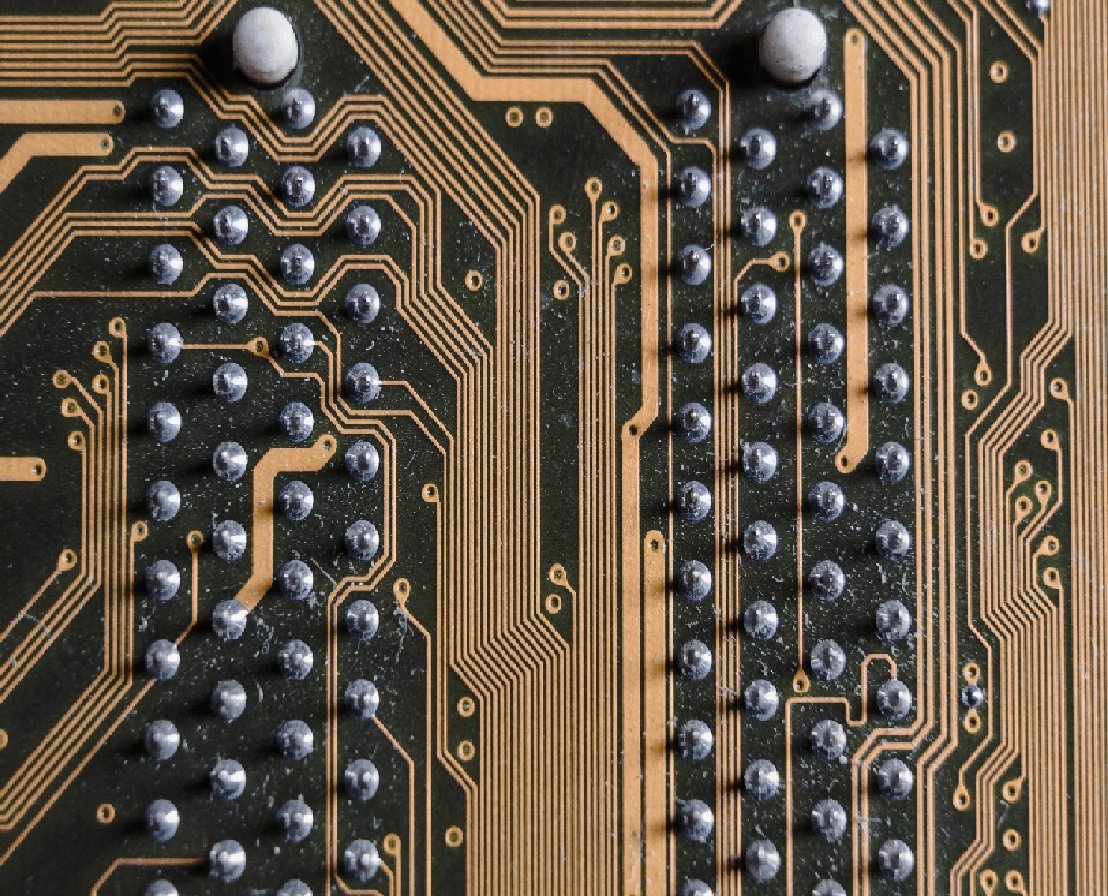

Introduction In today's era of advanced technology and sleek gadgets, it's hard to imagine a world without electronic devices that have become an integral part of our daily lives. From smartphones to laptops, smartwatches to home automation systems, the evolution of electronic devices has been nothing short of remarkable. In this blog post, we will explore the journey of electronic device history from the early days of registration to the advent of printed circuit boards (PCBs). Registration of Electronic Devices Before the widespread use of PCBs, electronic devices relied on a complex network of wires, tubes, and manual connections. The process of manufacturing electronic devices was tedious and time-consuming. Each connection had to be manually soldered and tested, making it an expensive and inefficient process. In the early days, electronic devices were not as small or portable as we know them now. They were bulky and often confined to specific locations such as laboratories or industrial settings. However, with the advancement of technology, engineers and designers began to explore ways to make these devices more compact and user-friendly. Enter the Printed Circuit Boards The introduction of printed circuit boards revolutionized the electronics industry. A printed circuit board, commonly known as a PCB, is a thin board made of non-conductive material like fiberglass, with thin layers of conductive material etched onto it. These conductive paths, also known as traces, replace the need for manual wiring, making the manufacturing process much more efficient. PCBs brought numerous advantages to the electronic device industry. They provided a reliable platform for connecting various electronic components efficiently. The design and fabrication of PCBs allowed for the miniaturization of electronic devices, enabling compactness and portability. Additionally, PCBs improved the reliability and durability of devices, reducing maintenance costs. The PCB manufacturing process involves several steps, starting from the design and layout of the circuit on a computer-aided design (CAD) software. Once the design is finalized, it is transferred onto the PCB through a process called photolithography. This process involves light-sensitive materials and chemical etching to create the desired circuit paths. Afterward, the electronic components are soldered onto the board, and the device is ready for use. Impact on Electronic Device Innovation The advent of printed circuit boards had a significant impact on the innovation and development of electronic devices. With the simplification of the manufacturing process, companies and designers were able to create prototypes and test their ideas more swiftly. This led to the rapid advancement of technology and more affordable electronic devices. Moreover, the introduction of PCBs also paved the way for the mass production of electronic devices, making them accessible to a wider audience. The standardization of circuit board designs and the availability of off-the-shelf components made it easier for companies to manufacture electronic devices in large quantities, reducing costs and increasing market availability. Conclusion The history of electronic devices has come a long way, from the laborious process of manual registration to the innovation of printed circuit boards. PCBs have not only enhanced the functionality and reliability of electronic devices but also played a crucial role in shaping our modern world. As technology continues to advance, we can expect further improvements in the design, manufacturing, and performance of electronic devices, ensuring a bright and exciting future for the world of electronics. For a different angle, consider what the following has to say. http://www.edhr.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :