Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

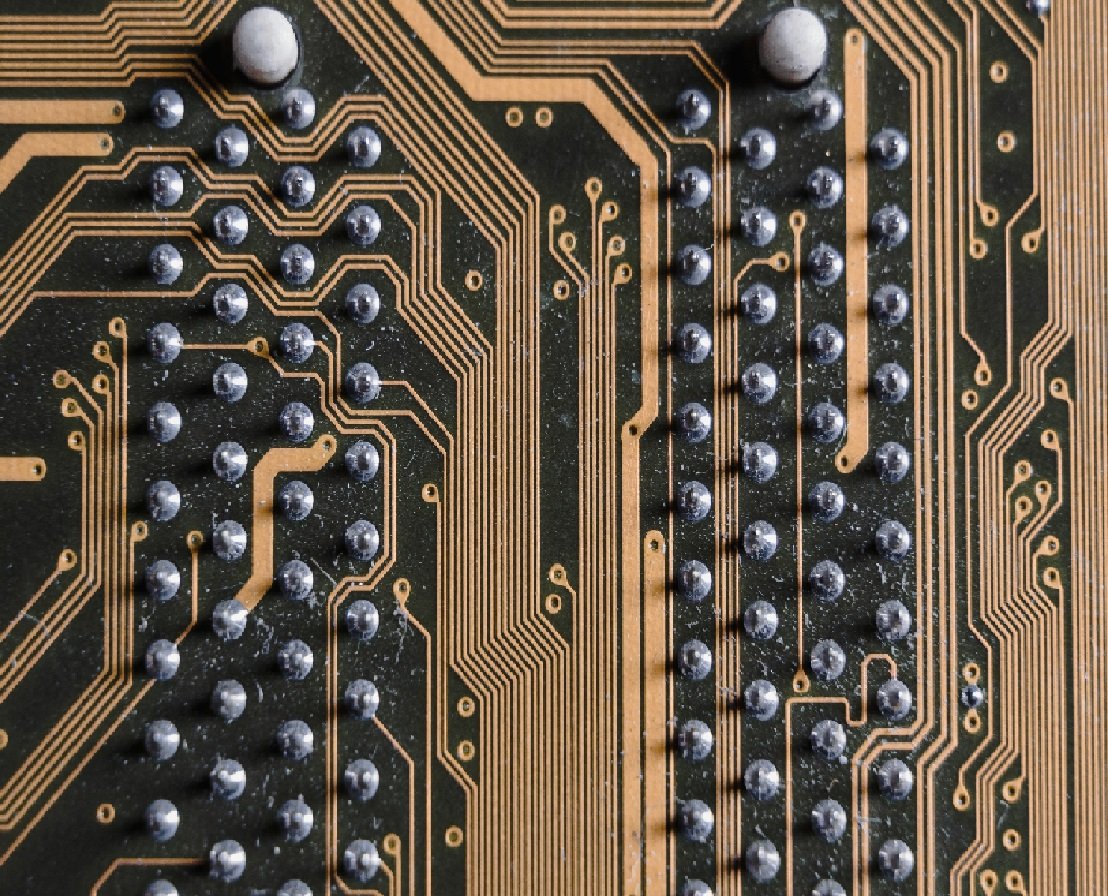

The history of electronic devices is a fascinating journey that spans over a century of innovation and development. From the early days of basic telegraph machines to today's advanced smartphones and laptops, electronic devices have evolved to become an integral part of our daily lives. In this blog post, we will explore the history of electronic devices and how quality assurance methods have played a crucial role in ensuring their reliability and performance.

Category : | Sub Category : Posted on 2025-11-03 22:25:23

The history of electronic devices dates back to the late 19th century, with the invention of the telegraph machine by Samuel Morse. This revolutionary device used electrical signals to transmit messages over long distances, laying the foundation for future advancements in communication technology. Over the years, electronic devices continued to evolve, with the invention of the telephone, radio, and television, among others. As electronic devices became more complex and sophisticated, the need for quality assurance methods became increasingly important. Quality assurance involves ensuring that electronic devices meet certain standards of performance, reliability, and safety. This is achieved through a variety of methods, including testing, inspection, and certification. One common quality assurance method used in the production of electronic devices is testing. Testing involves subjecting devices to various conditions and scenarios to evaluate their performance and identify any potential issues. This can include testing for durability, functionality, and compatibility with other devices. In addition to testing, inspection is another key quality assurance method used in the production of electronic devices. Inspection involves visually inspecting devices for any defects or abnormalities that could affect their performance. This can include checking for loose components, faulty wiring, or other issues that may impact the device's functionality. Certification is also an important quality assurance method for electronic devices. Certification involves obtaining approval from regulatory bodies or industry organizations that certify the device meets certain standards of quality and safety. This can include certifications for electromagnetic compatibility, safety standards, and environmental regulations. Overall, quality assurance methods play a crucial role in ensuring the reliability and performance of electronic devices. By implementing rigorous testing, inspection, and certification processes, manufacturers can produce high-quality devices that meet the needs and expectations of consumers. As electronic devices continue to evolve and become more advanced, quality assurance will remain a vital component of the production process. Visit the following website https://www.reactance.org Looking for more information? Check out https://www.cerrar.org To see the full details, click on: https://www.octopart.org For more info https://www.podimo.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

2 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →2 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →2 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →2 months ago Category :