Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Unveiling the Evolution: A Historic Journey of Surface Mount Technology in Electronics

Category : | Sub Category : Posted on 2023-10-30 21:24:53

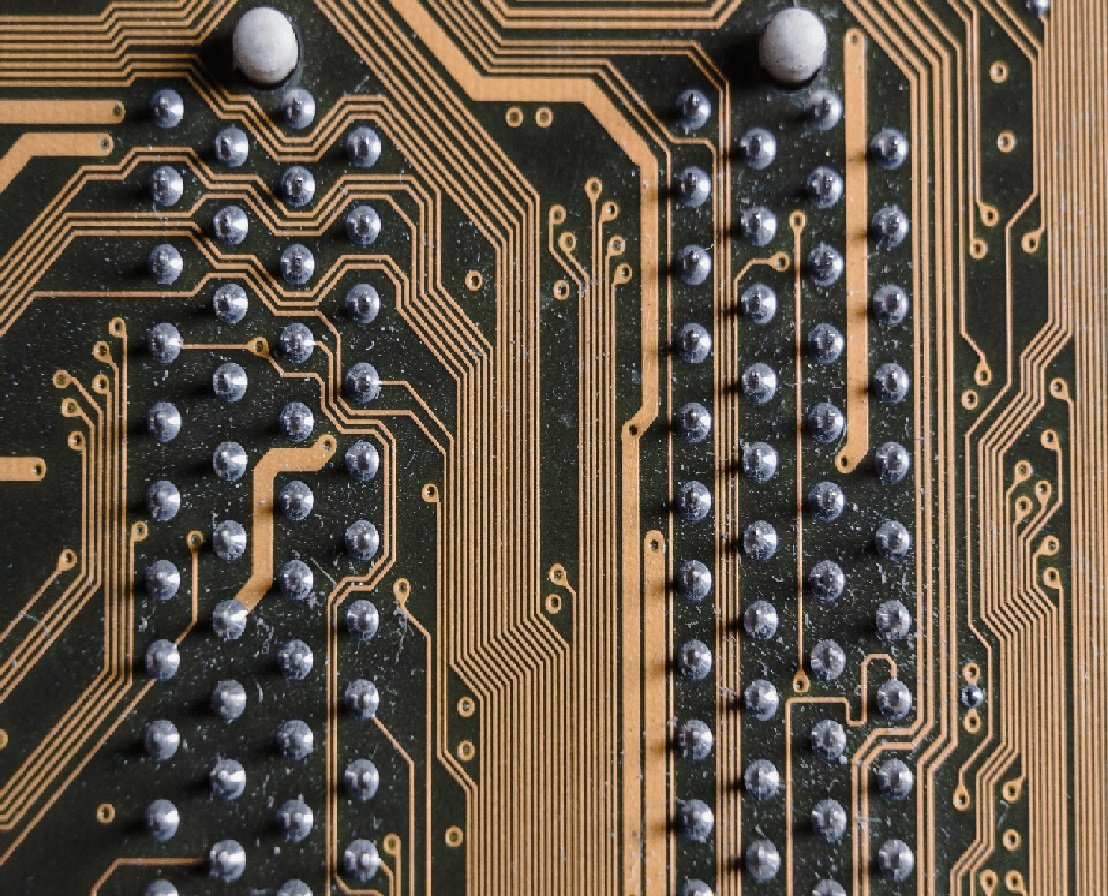

Introduction In the fast-paced world of electronics, technological advancements have been nothing short of remarkable. One such innovation that has revolutionized the industry is surface mount technology (SMT). SMT has made its mark by providing smaller, more efficient, and cost-effective electronic devices. In this blog post, we will delve into the history and registration of surface mount technology, tracing its origins and exploring its impactful role in modern electronics. The Birth of Surface Mount Technology Surface mount technology emerged in the mid-1960s as a response to the limitations of through-hole technology, which required drilling holes and manual soldering of components onto printed circuit boards (PCBs). Inspired by the need for increased efficiency, the search for an alternative led to the development of SMT. This new technique involved soldering components directly onto the surface of the PCB, eliminating the need for drilling holes and reducing both manufacturing time and cost. Early Adoption and Challenges Despite its breakthrough potential, surface mount technology faced initial resistance from manufacturers who were accustomed to through-hole technology. However, as the demand for miniaturized and lightweight electronic devices increased, SMT gained momentum. The adoption of SMT by the consumer electronics industry was a turning point, propelling this technology into the mainstream. One of the challenges faced by early adopters of SMT was the lack of standardized components and manufacturing processes. Each manufacturer had its own proprietary methods, making it difficult to achieve compatibility and interchangeability. To address this fragmentation, industry organizations and standards committees came together to establish common guidelines and standards, streamlining the manufacturing, assembly, and registration of surface mount components. Registration of Surface Mount Components The registration process for surface mount components plays a crucial role in ensuring compatibility and reliability in electronic devices. Registration involves the identification of specific characteristics of components such as dimensions, electrical parameters, and packaging. This information is typically recorded in standardized databases or specifications, allowing manufacturers and designers to select and integrate components seamlessly. Over time, registration requirements and standards have evolved to keep pace with the rapid advancements in surface mount technology. Organizations like the International Electrotechnical Commission (IEC) and the Joint Electron Device Engineering Council (JEDEC) have played significant roles in shaping and promoting standards such as IPC-7351 and EIA-481, which define registration guidelines for the electronic industry. The Impact of Surface Mount Technology on Modern Electronics The widespread adoption of surface mount technology has revolutionized the electronics landscape. The introduction of smaller, lighter, and more compact devices has been made possible by the efficiency and miniaturization capabilities of SMT. This technology has not only improved the performance and functionality of electronic devices but has also enabled the production of intricate designs that were previously unachievable with through-hole technology. Furthermore, SMT has facilitated the development of advanced features in consumer electronics, automotive, aerospace, telecommunications, and many other industries. This has led to the proliferation of smartphones, tablets, wearables, and smart home devices that have become an integral part of our daily lives. Conclusion The journey of surface mount technology in electronics has been a remarkable one. From its early days of resistance and fragmentation to becoming an integral part of modern electronic manufacturing, SMT has transformed the industry. The registration of surface mount components has played a pivotal role in enabling the compatibility and interchangeability of these components, fostering efficiency and innovation. As technology continues to evolve, SMT is poised to keep pushing boundaries, driving the development of even more advanced and efficient electronic devices. Visit the following website http://www.edhr.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :