Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Tracing the Evolution: A Brief History of Through-Hole Technology in Electronics

Category : | Sub Category : Posted on 2023-10-30 21:24:53

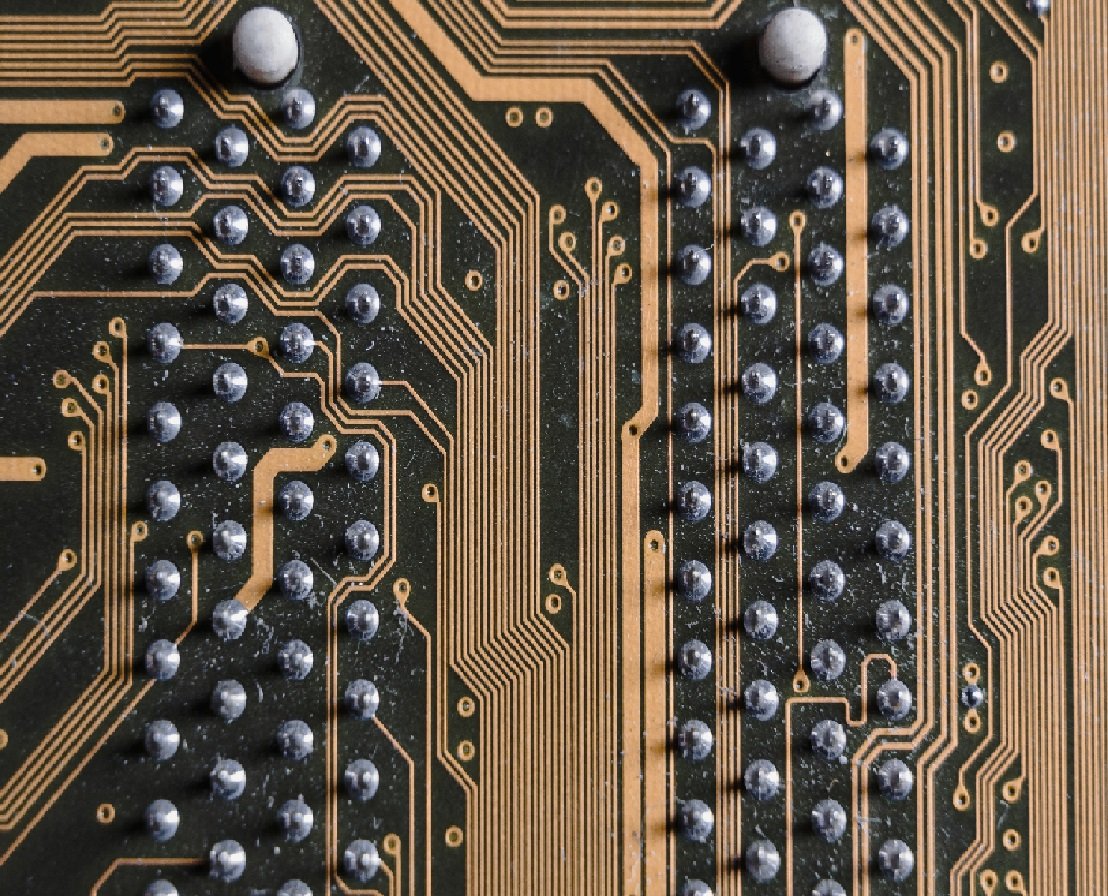

Introduction: Electronic devices have become an integral part of our daily lives, from smartphones and laptops to household appliances and automobiles. Behind this technological revolution lies the evolution of electronic components and manufacturing techniques. One such technique, through-hole technology, has played a crucial role in shaping the history of electronics registration. In this blog post, we will delve into the fascinating journey of through-hole technology and its impact on the electronics industry. What is Through-Hole Technology? Through-hole technology, also known as TH Technology, is a method of constructing electronic circuits using components with leads passed through holes on the PCB (printed circuit board) and then soldered on the opposite side. This technique, introduced in the mid-20th century, has been widely used for its reliability, robustness, and ability to withstand mechanical stress. The Birth of Through-Hole Technology: Before the advent of through-hole technology, point-to-point wiring was the prevalent method of building electronic circuits. However, this approach was time-consuming, cumbersome, and prone to errors, making it difficult to mass-produce electronic devices. In the 1940s, as electronics started to gain popularity, the need for a more efficient manufacturing technique became evident. Invention of the Printed Circuit Board (PCB): As the demand for electronic devices grew, so did the need for a more streamlined manufacturing process. In 1943, Paul Eisler, an Austrian engineer, invented the first prototype of the printed circuit board. His creation marked a significant milestone in the history of electronics, as it paved the way for through-hole technology. The Rise of Through-Hole Technology: With the introduction of PCBs, the stage was set for through-hole technology to dominate electronic manufacturing. This technique involved mounting components with leads on one side of the PCB and using holes to connect them to the other side, where the solder joints were formed. Through-hole technology provided a more efficient and reliable method of assembling electronic devices, allowing for faster production rates and improved quality control. Advantages of Through-Hole Technology: Through-hole technology revolutionized the electronics industry in several ways: 1. Mechanical Strength: Through-hole components are mechanically stronger and more resistant to shock and vibrations, making them suitable for applications where durability is crucial, such as automotive electronics and aerospace systems. 2. Component Selection: Through-hole components offer a wider variety of choices compared to surface-mount technology (SMT), allowing for better customization and integration of different functionalities into electronic devices. 3. Repairability: Through-hole components are relatively easy to repair or replace, as they can be easily desoldered and replaced individually. 4. Heat Dissipation: Through-hole components can handle higher power dissipation, making them suitable for devices that generate significant heat, such as power supplies and amplifiers. The Transition to Surface Mount Technology (SMT): While through-hole technology played a dominant role in the electronics industry for several decades, it eventually started to lose its ground to surface mount technology (SMT). SMT offered smaller component sizes, higher component density, and lower production costs, making it more suitable for compact and lightweight electronic devices. With the rise of miniaturization trends in the late 20th century, SMT became the preferred choice for many manufacturers. Conclusion: Through-hole technology has left an indelible mark on the history of electronic device registration. Its introduction paved the way for efficient and reliable manufacturing processes, revolutionizing the electronics industry. While its dominance has diminished with the emergence of surface mount technology, through-hole technology continues to hold significance in certain applications. Understanding the evolution of through-hole technology provides valuable insights into the rich history of electronic device manufacturing, highlighting the constant quest for innovation and efficiency. For valuable insights, consult http://www.edhr.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :