Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Understanding Electronic Products and Electromagnetic Compatibility

Category : | Sub Category : Posted on 2023-10-30 21:24:53

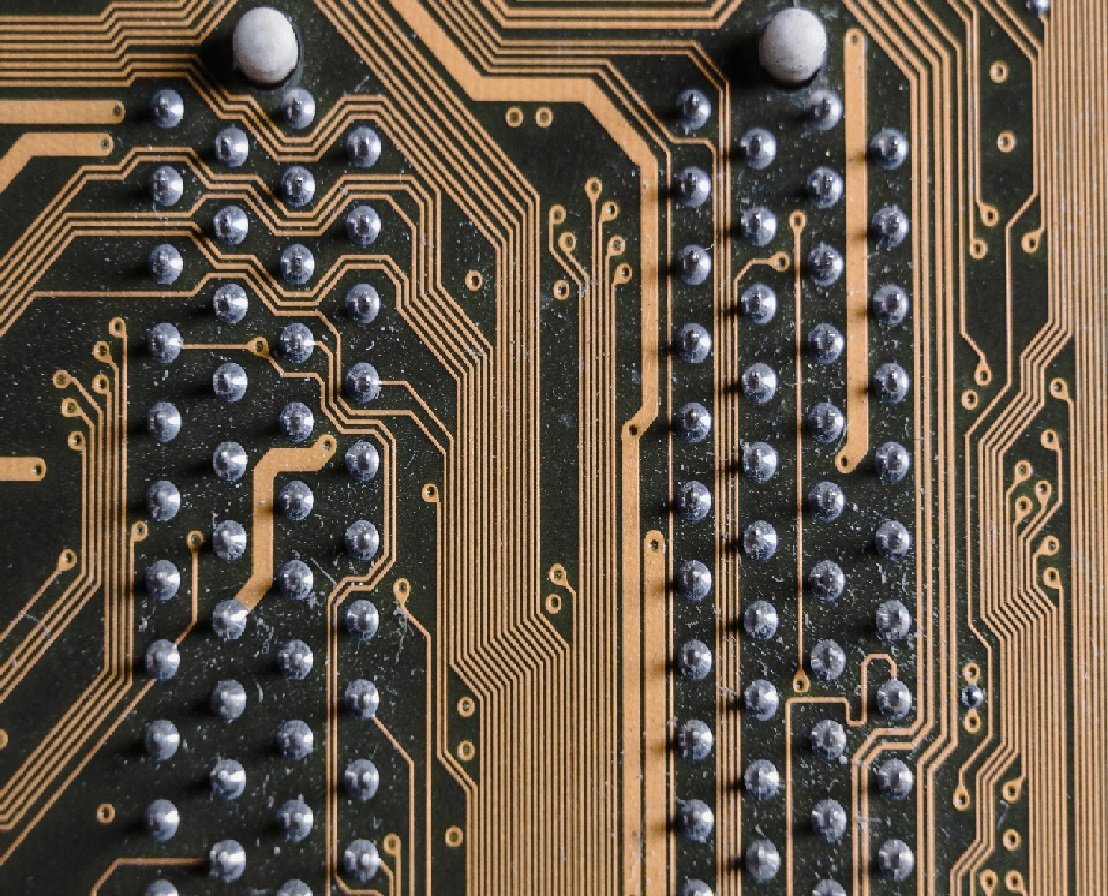

Introduction: In today's technology-driven world, electronic products surround us everywhere we go. From smartphones and laptops to home appliances and medical devices, electronic devices have become an integral part of our lives. However, have you ever wondered how these devices coexist without interfering with each other's functionality? The answer lies in a concept known as electromagnetic compatibility (EMC). In this blog post, we will explore what electronic products EMC is, why it is important, and how it is achieved. What is Electromagnetic Compatibility (EMC)? EMC refers to the ability of electronic devices to function correctly in their intended electromagnetic environment without causing electromagnetic interference (EMI) to other devices. Every electronic product generates electromagnetic energy as a byproduct of its operation, which, if not properly managed, can cause disruptions or malfunctions in other nearby devices. Importance of EMC in Electronic Products: Ensuring EMC is crucial for various reasons, including: 1. Consumer Safety: EMC compliance ensures that electronic products will not cause harm to users or interfere with critical equipment like medical devices or aircraft systems. 2. Reliability: Uncontrolled electromagnetic interference can lead to malfunctions or even complete failure of electronic products, compromising their reliability and performance. 3. Legal and Regulatory Compliance: Many countries have specific standards and regulations regarding EMC that manufacturers must meet to bring their electronic products to market. 4. Avoiding Financial Losses: Non-compliance with EMC standards can result in costly product recalls, fines, or legal actions, leading to significant financial losses for manufacturers. How is EMC Achieved in Electronic Products? To achieve EMC, manufacturers must consider both the emissions (radiated and conducted) and the susceptibility (immunity) of their electronic products. Here are some key measures taken during the design and testing phase: 1. Grounding and Shielding: Proper grounding and shielding techniques help minimize the emissions and susceptibility of electronic products. This involves using conductive materials and enclosures to contain and redirect electromagnetic energy. 2. Filtering: Employing filters on power supply lines and signal lines helps attenuate unwanted electromagnetic noise, reducing the chances of interference with other devices. 3. Compliance Testing: Manufacturers subject their electronic products to rigorous EMC compliance testing. This involves evaluating the emissions and immunity characteristics to ensure they meet the required standards. 4. Design for EMC: EMC considerations should be incorporated into the design process from the early stages. Proper component placement, PCB layout, and circuit design techniques can significantly minimize EMI risks. Conclusion: Electromagnetic compatibility is crucial for the seamless coexistence and functionality of electronic products. With the increasing complexity and density of electronic devices, ensuring EMC has become more challenging but equally important. Manufacturers must employ proper design practices, effective shielding, and compliance testing to meet the required EMC standards. By doing so, they can ensure user safety, minimize electromagnetic interference, and bring reliable and compliant products to market. Want a deeper understanding? http://www.wootalyzer.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :