Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

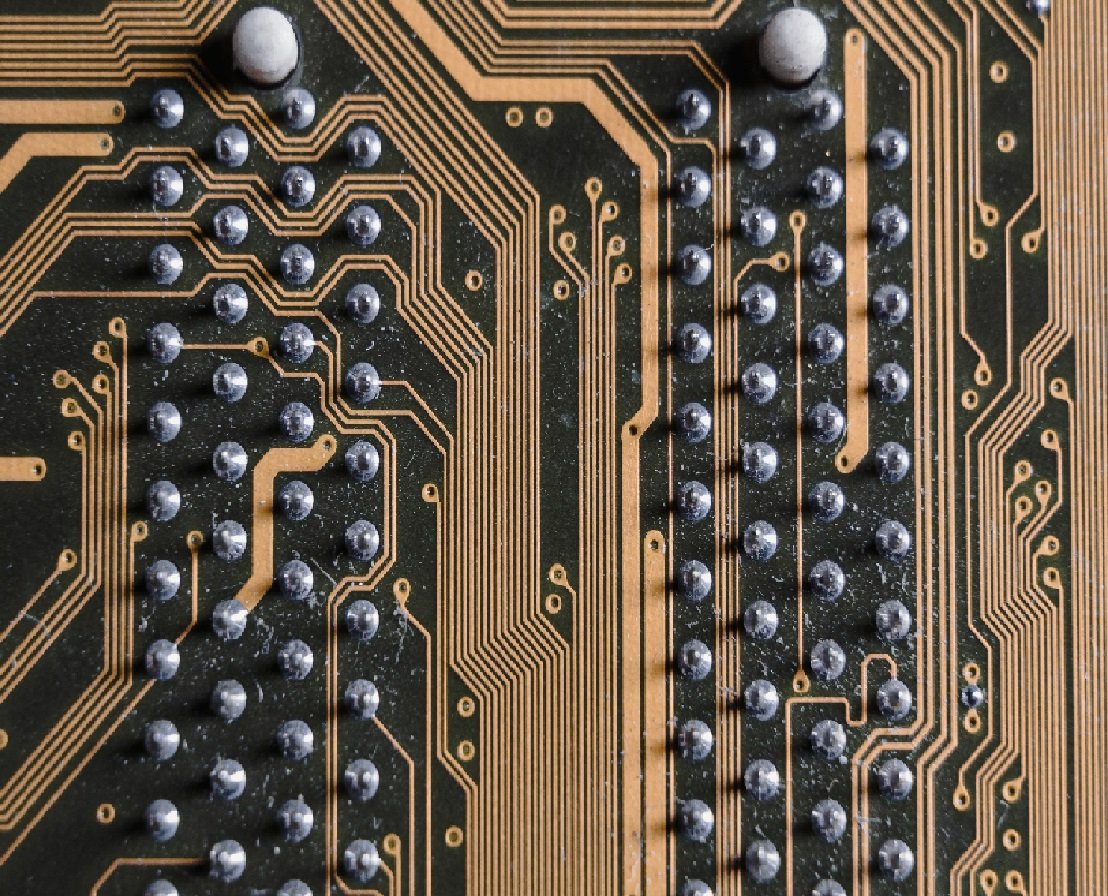

A Closer Look at Electronic Products: Understanding and Analyzing Electronics Failures

Category : | Sub Category : Posted on 2023-10-30 21:24:53

Introduction: In today's digital age, electronic products have become an integral part of our lives. From smartphones and laptops to household appliances and automotive systems, electronic devices are everywhere. However, despite their widespread use, electronics failures are not uncommon. Understanding why electronic products fail and analyzing these failures is crucial for manufacturers, consumers, and tech enthusiasts alike. In this article, we will delve into the fascinating world of electronics failure analysis. 1. What Causes Electronics Failures? Electronics failures can be attributed to various factors, ranging from design flaws and manufacturing defects to improper handling and environmental conditions. Common causes of electronics failures include: a) Overheating: Excessive heat can damage sensitive components and lead to circuitry malfunctions. Poor ventilation, inadequate cooling systems, or excessive workload can all contribute to overheating. b) Power Surges and Voltage Spikes: Sudden spikes in power supply voltage can overwhelm electronic components, causing them to fail. Power surges may be the result of lightning strikes, faulty wiring, or problems with the electrical grid. c) Environmental Factors: Dust, moisture, humidity, and extreme temperatures can all have detrimental effects on electronic devices. Exposure to these elements can corrode circuits, degrade solder joints, and cause short circuits. d) Component Failure: Inherent issues with individual components, such as capacitors, transistors, or integrated circuits, can cause electronics failures. These failures may stem from manufacturing defects, aging, or technical issues. 2. The Importance of Electronics Failure Analysis: Understanding why electronic products fail is essential for several reasons: a) Improving Product Reliability: By identifying the root causes of failures, manufacturers can design and produce more reliable electronic products. Failure analysis helps engineers identify weak points in designs, materials, or manufacturing processes, leading to iterative improvements. b) Enhancing Customer Satisfaction: Electronics failures can lead to customer dissatisfaction and negative brand perception. Analyzing failures enables manufacturers to address issues promptly and improve product quality, ultimately enhancing customer satisfaction. c) Identifying Warranty Claims: Electronics failure analysis plays a crucial role in determining warranty claims. Manufacturers can use failure analysis to differentiate between failures caused by manufacturing defects and those due to user misuse or external factors. d) Accelerating Technological Advancements: Studying failures provides valuable insights into the limitations of current technologies. This knowledge can drive technological advancements, leading to the development of more robust and efficient electronic products. 3. Methods and Techniques for Electronics Failure Analysis: Electronics failure analysis involves a multidisciplinary approach, combining various techniques and methods. Some commonly used methods include: a) Visual Inspection: Visual inspection allows experts to identify visible signs of damage, corrosion, burn marks, or other physical anomalies. It provides essential initial clues to pinpoint the failure's root cause. b) Non-Destructive Testing: Techniques like X-ray inspection, thermal imaging, and ultrasound testing allow engineers to assess internal components and identify potential defects without damaging the device. c) Destructive Testing: In some cases, failure analysis requires the physical disassembly and testing of components. This includes techniques like cross-sectioning, microscopy, and chemical analysis to examine the structure and composition of failed components. d) Electrical Testing: Electrical testing involves analyzing the electrical behavior of circuits and components using specialized equipment. It helps experts determine if a component's failure is due to a short circuit, open circuit, or other electrical anomalies. Conclusion: Electronic products have revolutionized our lives, but failures can still occur. Understanding the causes and analyzing these failures is critical for improving product reliability, enhancing customer satisfaction, determining warranty claims, and accelerating technological advancements. By investing in electronics failure analysis, manufacturers can create more durable and reliable electronic devices, ensuring a smoother user experience and a more sustainable technological future. Have a look at the following website to get more information http://www.wootalyzer.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :