Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Surface Mount Technology: Revolutionizing Electronics

Category : | Sub Category : Posted on 2023-10-30 21:24:53

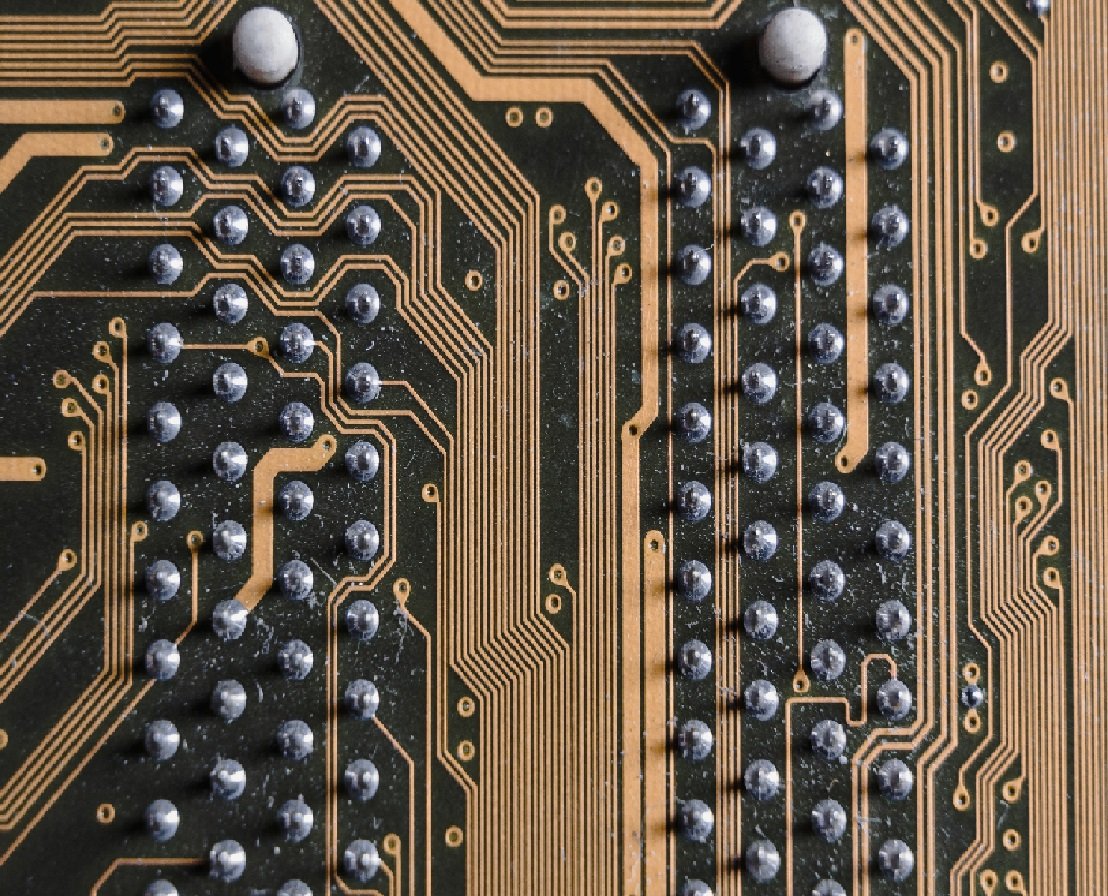

Introduction: In the world of electronics, advancements are made at a rapid pace, leading to smaller, faster, and more efficient devices. One such innovation that has revolutionized the industry is Surface Mount Technology (SMT). This technology has not only changed the manufacturing process but has also made a significant impact on the performance and functionality of electronic products. In this blog post, we will explore the fascinating world of surface mount technology and its influence on modern electronics. What is Surface Mount Technology? Surface Mount Technology, commonly known as SMT, refers to a method of assembling electronic circuits in which the components are mounted directly onto the surface of the printed circuit board (PCB). Unlike the traditional through-hole technology, which requires the components to be inserted into drilled holes on the board, SMT components are smaller and lighter, making them easy to solder onto the PCB. Advantages of SMT: 1. Miniaturization: One of the key benefits of SMT is its ability to accommodate smaller and lighter components. As a result, electronic products have become more compact and portable, without compromising on performance. 2. Higher Component Density: SMT enables higher component density on PCBs compared to through-hole technology. This allows for more features and functionalities in a limited space, making electronic devices more powerful and versatile. 3. Increased Speed and Efficiency: Surface mount components lead to shorter electrical paths, minimizing signal distortion and optimizing the electronic system's overall speed and efficiency. This makes SMT-based products ideal for high-speed and high-performance applications. 4. Cost-Effectiveness: SMT eliminates the need for drilling holes in PCBs, reducing manufacturing costs. Additionally, the automated assembly process of SMT reduces labor costs and enhances production efficiency, making it a cost-effective choice for large-scale manufacturing. Applications of SMT: Surface Mount Technology finds applications in various industries, including consumer electronics, telecommunications, automotive, medical devices, and aerospace. From smartphones and tablets to advanced medical equipment and automotive sensors, SMT has become an indispensable part of modern electronics. Challenges and Future Trends: While SMT has drastically improved the electronic manufacturing process, it presents its own set of challenges. The small size of SMT components makes it difficult to manually solder them, requiring specialized equipment such as reflow ovens and pick-and-place machines. However, the industry is continuously innovating to address these challenges and develop more efficient and reliable assembly techniques. Looking ahead, the future of surface mount technology is bright. As the demand for smaller, faster, and more technologically advanced electronic products continues to rise, SMT will play a crucial role. The ongoing miniaturization of components, improved manufacturing techniques, and the emergence of new materials are expected to further enhance SMT capabilities and inspire new possibilities in electronic design. Conclusion: Surface Mount Technology has transformed the electronics industry, enabling the development of smaller, more powerful, and cost-effective electronic devices. With its advantages in miniaturization, higher component density, speed, and efficiency, SMT has become the go-to technology for manufacturing electronic products. As we move towards a more connected and digital future, the role of surface mount technology will only continue to expand, shaping the way we live and interact with technology. To get more information check: http://www.wootalyzer.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :