Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Surface Mount Technology: Revolutionizing Electronics in the Employment and Job Market

Category : | Sub Category : Posted on 2023-10-30 21:24:53

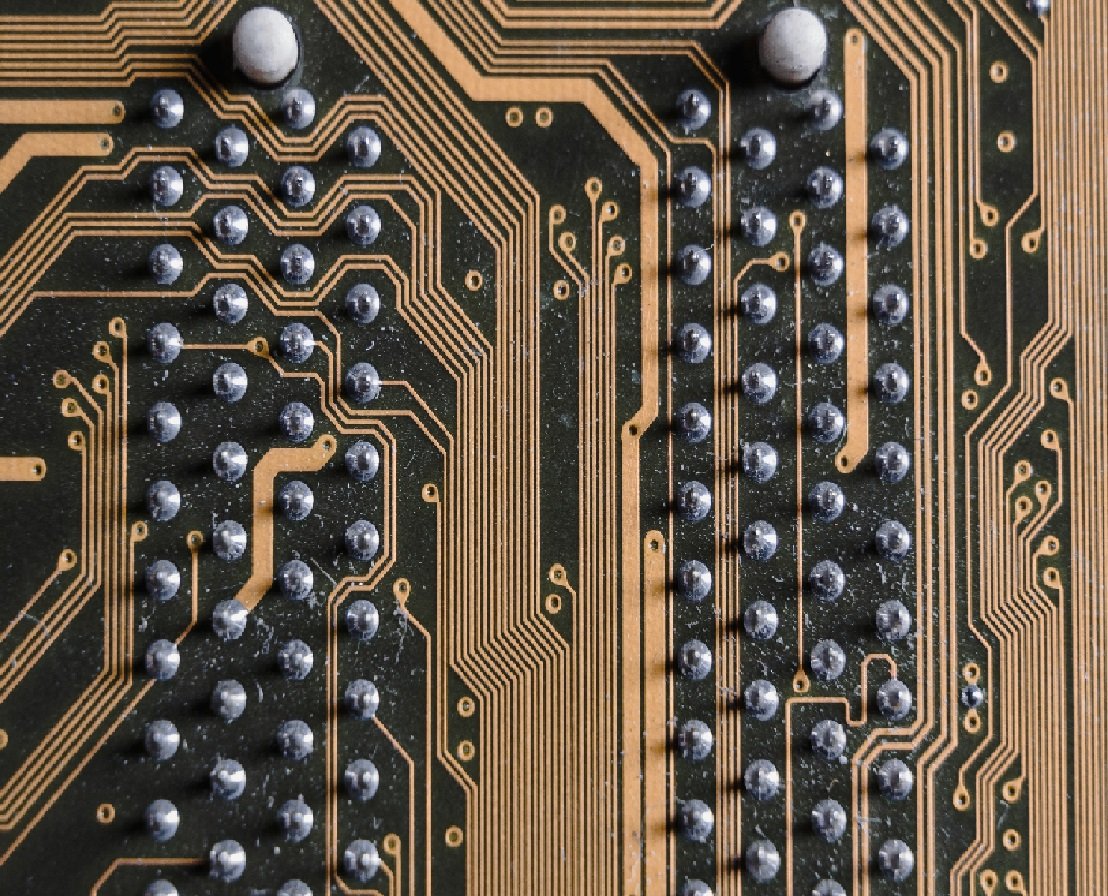

Introduction: In today's fast-paced world, technology is constantly evolving, and with it, the demand for skilled professionals in the electronics industry. One significant advancement that has changed the landscape of electronics manufacturing is Surface Mount Technology (SMT). This cutting-edge technique has not only transformed how electronic components are mounted onto circuit boards but has also had a profound impact on the employment and job market within the industry. In this blog post, we will explore the role of Surface Mount Technology in the employment and job market of electronics. What is Surface Mount Technology? Surface Mount Technology, commonly known as SMT, is a method of assembling electronic circuits by mounting components directly onto the surface of printed circuit boards (PCBs). Unlike traditional techniques such as through-hole mounting, which require wires and leads to be soldered, SMT utilizes specialized machinery to place and solder miniature components on the top surface of the PCB. Increased Demand for SMT Specialists: As electronics manufacturers transition from through-hole technology to SMT, the demand for professionals skilled in surface mount technology has skyrocketed. Companies across various industries, including consumer electronics, automotive, telecommunications, and medical devices, are now heavily reliant on SMT for their product manufacturing. This shift has created a surge in job opportunities for individuals well-versed in SMT techniques. Job Roles and Responsibilities: Surface mount technology has created new job roles within the electronics industry. These roles include SMT operators, process engineers, quality control inspectors, and equipment technicians. SMT operators play a crucial role in operating and maintaining the automated machinery used in SMT assembly lines, while process engineers ensure the smooth functioning and optimization of the manufacturing processes. Quality control inspectors are responsible for verifying the accuracy and functionality of SMT components, and equipment technicians handle the maintenance and troubleshooting of SMT machines. Skill Development and Training: With the rising demand for SMT professionals, companies are investing in training programs and certifications to develop a skilled workforce. Many technical schools, vocational institutes, and electronics companies offer specialized training courses in surface mount technology. These programs cover topics such as component identification, soldering techniques, machine programming, and quality control. By acquiring the necessary skills and certifications in SMT, individuals can enhance their employability in the electronics job market. Impacts on the Job Market: The advent of SMT has led to significant shifts in the job market for electronics professionals. While traditional through-hole assembly techniques are still relevant in certain applications, the industry's overall focus has shifted toward SMT. This shift has resulted in a decline in job opportunities for those specialized in through-hole assembly, while simultaneously creating an increased demand for SMT specialists. Consequently, individuals looking to enter or progress in the electronics industry are encouraged to familiarize themselves with SMT to stay competitive. Conclusion: Surface Mount Technology has revolutionized the electronics industry, transforming the way electronic components are mounted on PCBs. This technological advancement has had a profound impact on the employment and job market within the industry. The rising demand for SMT specialists has led to the creation of new job roles and increased opportunities for those skilled in SMT techniques. As the electronics industry continues to evolve, staying up-to-date with surface mount technology is essential for individuals looking to succeed in the ever-evolving job market. Have a look at the following website to get more information http://www.svop.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :