Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Soldering Techniques that Revolutionize the Exhibition Industry

Category : | Sub Category : Posted on 2023-10-30 21:24:53

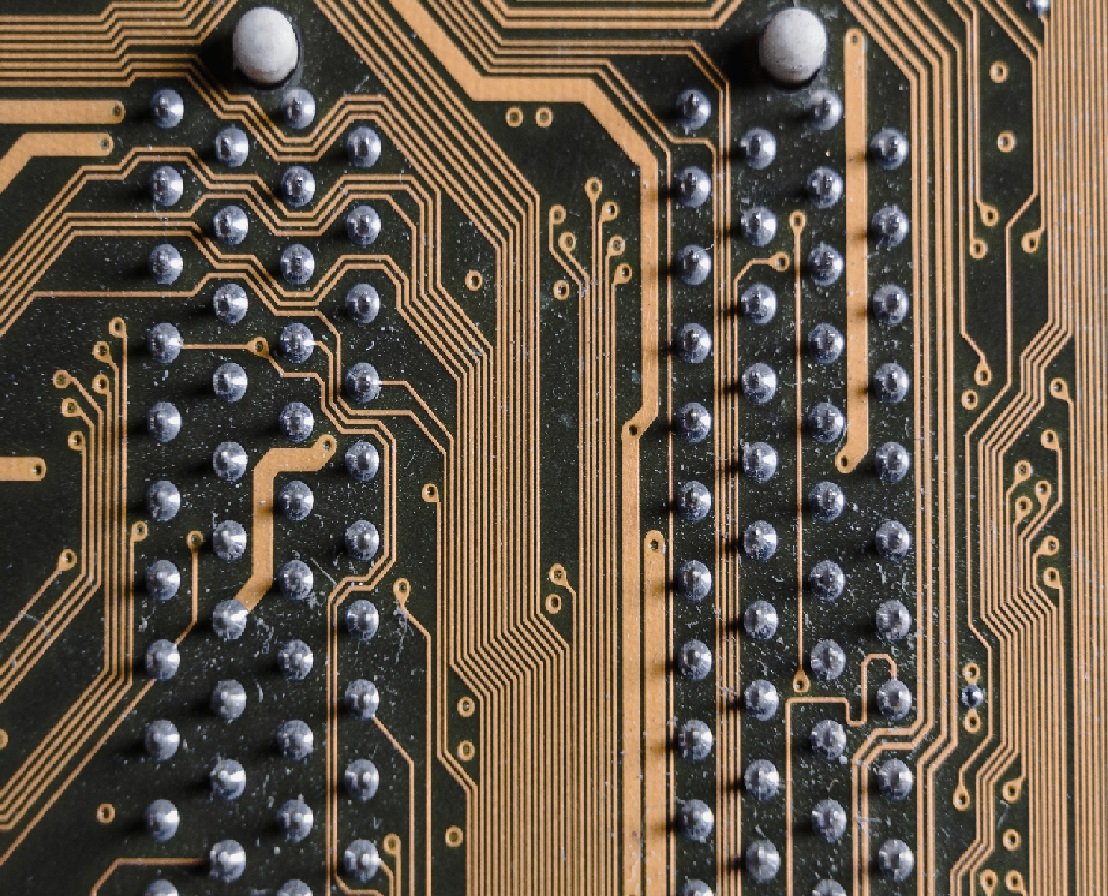

Introduction: The exhibition industry relies heavily on quality craftsmanship and attention to detail to create immersive and visually striking experiences for attendees. One crucial aspect of exhibition construction that often goes unnoticed is soldering. Soldering techniques play a vital role in ensuring the longevity and stability of exhibition setups. In this article, we will dive into the world of soldering techniques and explore how they have revolutionized the exhibition industry. 1. Why Soldering? Soldering is the process of joining two metal components using a molten filler material called solder. This technique offers various benefits that make it indispensable in the exhibition industry. Soldered connections provide excellent conductivity, superior strength, and durability, ensuring that exhibits withstand the rigors of transportation, assembly, and disassembly. Moreover, soldering allows for precise and intricate connections, enabling designers to create complex and intricate exhibition displays. 2. Soldering Techniques in the Exhibition Industry a. Through-Hole Soldering: Through-hole soldering is a popular technique used in the exhibition industry to connect components on printed circuit boards (PCBs). It involves inserting the leads of electronic components through pre-drilled holes on the PCB and then soldering them on the underside. This technique ensures strong mechanical and electrical connections, ideal for exhibitions with interactive elements. b. Surface Mount Technology (SMT): SMT has become a game-changer in the exhibition industry. Unlike through-hole soldering, SMT involves soldering components directly onto the surface of the PCB. This technique offers several advantages, including smaller component sizes, reduced weight, and increased design flexibility. SMT has fueled the development of sleek and visually stunning exhibition displays. c. Wave Soldering: In mass production of exhibition components, wave soldering is often utilized. This technique involves moving the PCB across a wave of molten solder, allowing the solder to flow and create secure connections on both sides of the board. Wave soldering offers fast and reliable soldering, making it efficient for large-scale exhibition projects. 3. Lead-Free Soldering As environmental concerns grow, the exhibition industry is also shifting towards lead-free soldering techniques. Lead-free solder eliminates the risk of lead contamination, making it safer for both manufacturers and end-users. While the transition may present certain challenges due to the different properties of lead-free solder, the benefits of environmental sustainability and health cannot be overlooked. 4. Advanced Soldering Equipment The exhibition industry constantly strives to incorporate the latest technologies to enhance the quality and efficiency of soldering. Advanced soldering equipment, such as automated soldering robots and reflow ovens, have streamlined the soldering process, increasing productivity and improving the overall quality of exhibition installations. These advancements have allowed exhibitors to focus more on creativity and innovation instead of spending excessive time on manual soldering tasks. Conclusion: Soldering techniques have become indispensable in the exhibition industry, ensuring the stability, functionality, and longevity of exhibit displays. Through-hole soldering, surface mount technology, wave soldering, and lead-free soldering are just a few examples of the techniques that have revolutionized the industry. As technology continues to progress, we can expect further advancements in soldering techniques that will drive the exhibition industry to new heights of creativity and excellence. Uncover valuable insights in http://www.svop.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :