Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Revolutionizing Electronics Manufacturing: The Role of Surface Mount Technology in the Exhibition Industry

Category : | Sub Category : Posted on 2023-10-30 21:24:53

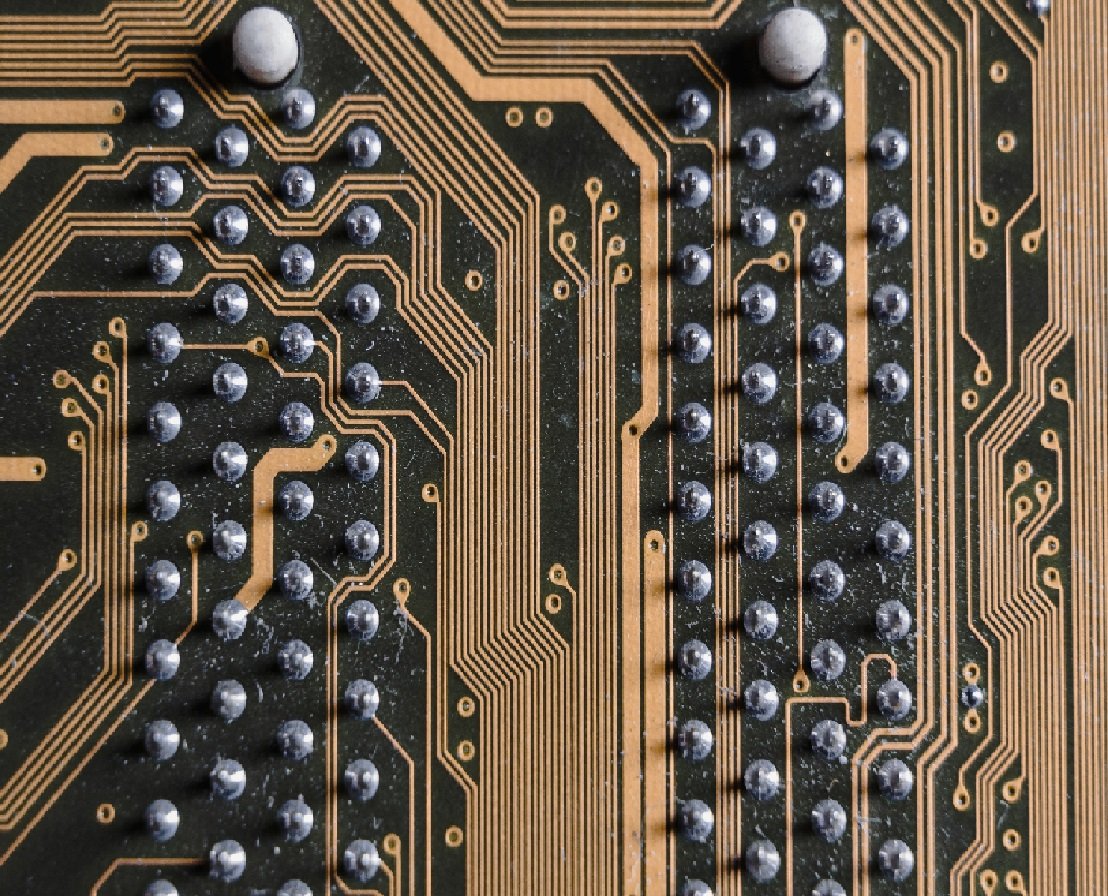

Introduction: The exhibition industry is constantly evolving, with new advancements in technology revolutionizing the way we showcase products and engage with audiences. One such innovation that has played a major role in transforming the industry is Surface Mount Technology (SMT) in electronics manufacturing. In this blog post, we will explore how SMT has reshaped the landscape of the exhibition industry, enabling exhibitors to create cutting-edge displays and experiences for their audiences. Understanding Surface Mount Technology (SMT): Surface Mount Technology is a method used to mount electronic components onto printed circuit boards (PCBs), eliminating the need for conventional through-hole components. Instead of traditional leads that pass through the PCB, surface mount components have small metal tabs or leads that are soldered directly to the board's surface. This creates a more efficient and compact design, allowing for greater design flexibility and reducing production costs. Benefits of SMT in the Exhibition Industry: 1. Miniaturization: SMT allows for the miniaturization of electronic components, leading to sleeker and more compact exhibition displays. This means exhibitors can make their products and technology more portable, saving valuable booth space and making it easier to transport their exhibits to different locations. 2. Design Flexibility: With SMT, exhibitors have greater freedom in designing their displays. The smaller size of surface mount components allows for more complex board designs, enabling exhibitors to create visually stunning, interactive, and immersive experiences for attendees. From interactive touchscreens to LED walls and augmented reality showcases, SMT empowers exhibitors to push the boundaries of creativity. 3. Improved Performance: Surface mount components offer superior electrical performance compared to through-hole components. With SMT, exhibitors can incorporate advanced sensors, microcontrollers, and processors into their displays, resulting in enhanced functionality and interactivity. This allows for the integration of smart features like real-time data monitoring, interactive presentations, and personalized user experiences. 4. Cost Efficiency: SMT offers cost advantages in terms of production and assembly. The automated nature of SMT assembly reduces labor costs, lowers the chances of human error, and increases production speed. Moreover, the miniaturization of components reduces the material costs and often allows for the use of less expensive materials without compromising quality. 5. Reliability and Durability: Surface mount components have proven to be more reliable and durable compared to through-hole components. Exhibitions often involve transporting displays, setting up and dismantling equipment, and enduring multiple handling cycles. SMT components are less prone to damage due to their smaller, low-profile design, ensuring exhibitors can offer consistent and reliable performances. Conclusion: Surface Mount Technology has become a game-changer in the exhibition industry, enabling exhibitors to create visually impressive, interactive, and functional displays. By embracing SMT, exhibitors can leverage its benefits, including miniaturization, design flexibility, improved performance, cost efficiency, and increased reliability. With SMT, the exhibition industry continues to push the boundaries of innovation, captivating audiences and providing unforgettable experiences. As technology continues to advance, we can expect SMT to play an even more significant role in shaping the future of exhibitions. Uncover valuable insights in http://www.svop.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :