Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Unveiling the Wonders of Through-Hole Technology in the Electronics Exhibition Industry

Category : | Sub Category : Posted on 2023-10-30 21:24:53

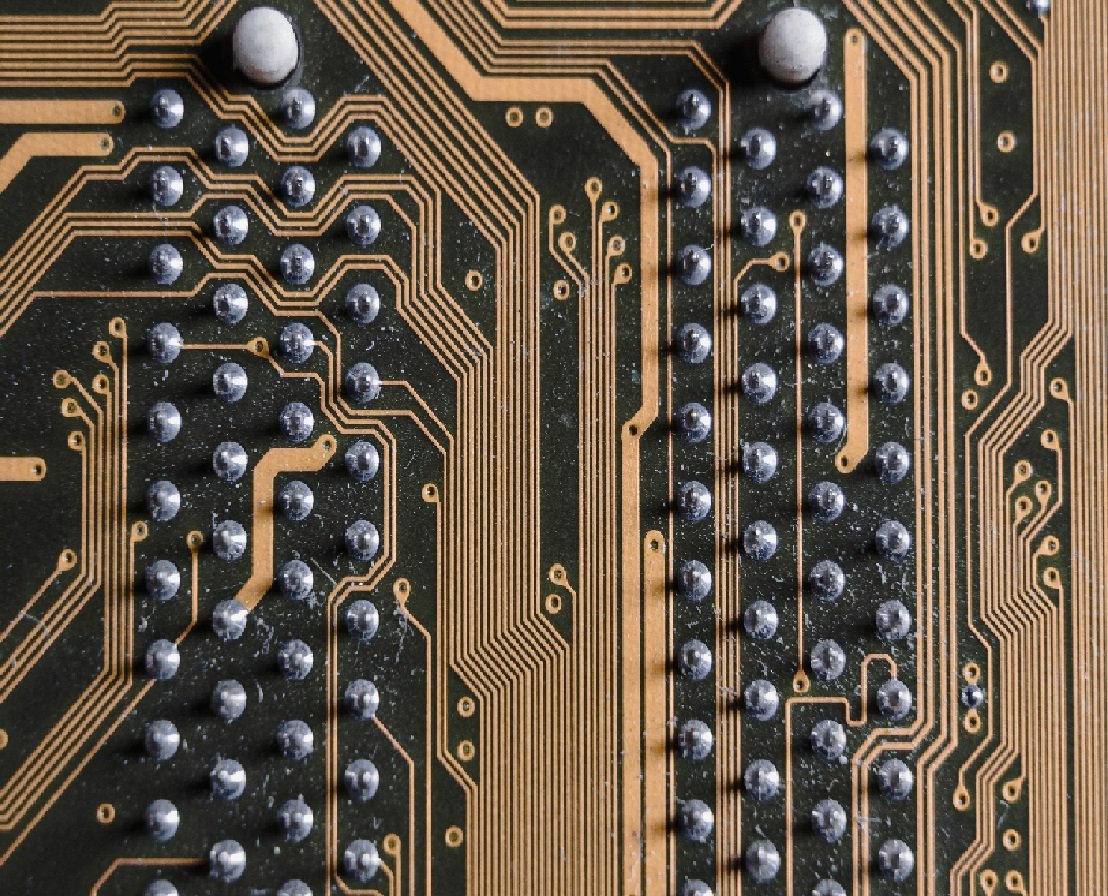

Introduction: In today's fast-paced and constantly evolving digital era, it's easy to overlook the humble components that power our electronic devices. However, within the exhibition industry, a technology known as through-hole technology plays a vital role. By enabling efficient and reliable connectivity, through-hole technology ensures the seamless operation of electronic devices showcased at exhibitions. In this article, we will delve into the essentials of through-hole technology and explore its significance within the exhibition industry. Understanding Through-Hole Technology: Through-hole technology is a method of constructing electronic circuits by inserting leads of components into holes drilled on the circuit board. These leads are then soldered onto the opposite side, creating sturdy connections. Although surface mount technology has gained popularity due to its smaller size and versatility, through-hole technology remains crucial in certain applications, particularly within exhibition setups. Why Through-Hole Technology Shines in Exhibitions: 1. Durability and Reliability: Exhibitions often involve transporting, assembling, and disassembling electronic setups multiple times. Through-hole technology offers robust connections that can withstand the rigors of these processes, ensuring the longevity and reliability of the exhibited devices. 2. Ease of Maintenance: The modular nature of through-hole components makes troubleshooting and replacing them relatively straightforward. This aspect proves invaluable when immediate repairs or component replacements are required during exhibitions, minimizing downtime and ensuring an uninterrupted showcase. 3. Enhanced Aesthetics: In some cases, exhibitions prioritize aesthetics, and the visual appeal of the showcased devices can impact visitors' perception. Through-hole components can be strategically placed to enhance the overall design, adding a touch of professionalism and attractiveness to the exhibited electronics. 4. Demonstrating Cutting-Edge Technologies: While surface mount technology dominates modern electronics, through-hole technology is still employed in specific applications that demand high power handling, improved heat dissipation, or shielding requirements. By incorporating through-hole components, exhibition participants can showcase the latest advancements and cutting-edge technologies that employ this traditional yet relevant assembly method. 5. Engaging Educational Opportunities: Exhibitions often serve as platforms to educate and inspire visitors. Through-hole technology offers an excellent opportunity to showcase the intricacies of electronic assembly to both professionals and enthusiasts. Visitors can witness firsthand how components are carefully soldered into place, fostering a deeper understanding and appreciation for the devices on display. Conclusion: Through-hole technology may seem like a relic in today's fast-paced electronics industry, but it remains an indispensable tool within the exhibition industry. Its unmatched durability, ease of maintenance, enhanced aesthetics, compatibility with niche applications, and educational value make it an invaluable asset in showcasing cutting-edge electronics. While surface mount technology may dominate daily life, through-hole technology shines bright on exhibition floors, ensuring a seamless and engaging experience for both exhibitors and visitors alike. also for More in http://www.svop.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :