Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Streamlining Grocery and Household Product Manufacturing with Surface Mount Technology Electronics

Category : | Sub Category : Posted on 2023-10-30 21:24:53

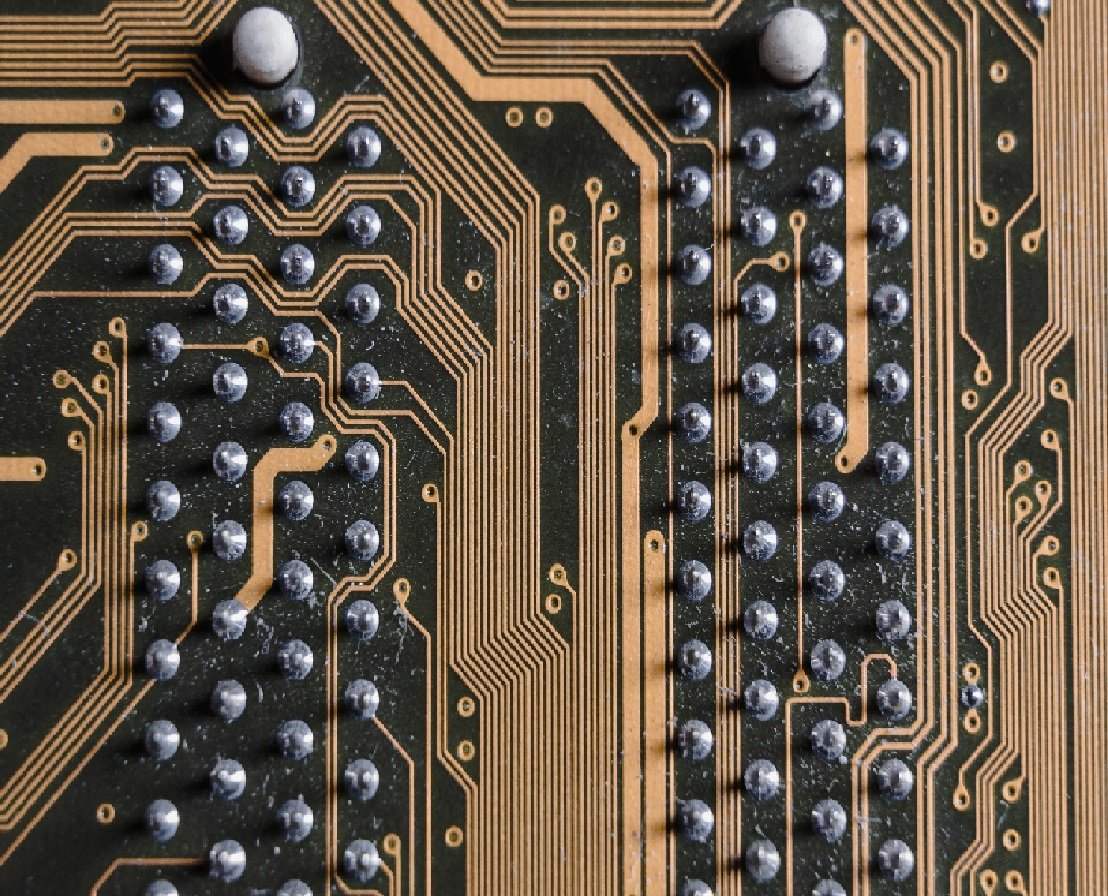

Introduction: The manufacturing industry is continually evolving, adopting new technologies to enhance efficiency and productivity. One such technology, surface mount technology (SMT) electronics, has revolutionized the production of various consumer goods, including grocery and household products. In this blog post, we will explore how SMT electronics have transformed the manufacturing process, leading to improved quality, reduced costs, and faster time to market for these essential products. What is Surface Mount Technology Electronics? Surface mount technology (SMT) is a method of electronic component placement and soldering that has largely replaced through-hole technology in electronic manufacturing. With SMT, electronic components are mounted directly onto the surface of printed circuit boards (PCBs), eliminating the need for drilling holes and inserting components. This technology enables smaller and more compact electronic designs, allowing manufacturers to optimize space utilization in their products. Benefits of SMT Electronics in Grocery and Household Product Manufacturing: 1. Enhanced Product Quality: The precision and accuracy of surface mount technology ensure reliable connections and minimize the chances of loose or faulty electrical connections. This results in improved overall product quality, reducing the odds of malfunctions or recalls that can be costly for manufacturers. 2. Space Optimization: Grocery and household products often have limited space for electronic components due to their size and functionality requirements. SMT electronics enable manufacturers to optimize space utilization by reducing the size and spacing between components on PCBs. This not only saves valuable physical space but also allows for more functionalities to be integrated into a smaller form factor. 3. Cost-Effective Production: SMT electronics offer cost advantages in terms of both production and material costs. Since SMT allows for automated assembly, manufacturers can achieve higher production volumes and reduce labor costs associated with manual component placement. Additionally, SMT enables the use of smaller and more affordable components, resulting in cost savings on materials. 4. Faster Time to Market: The streamlined production process provided by SMT electronics enables faster time to market for grocery and household products. With automated assembly and efficient component placement, manufacturers can meet consumer demands swiftly, minimizing delays in product launches and optimizing market competitiveness. 5. Flexibility and Scalability: SMT electronics provide flexibility and scalability in the manufacturing process. As consumer demands change, manufacturers can easily modify and update their product designs by replacing or upgrading components on the PCB without major redesign or production line reconfiguration. This adaptability allows manufacturers to stay ahead of market trends and consumer preferences. Conclusion: Surface mount technology electronics have transformed the manufacturing landscape for grocery and household products. The adoption of SMT electronics has allowed manufacturers to enhance product quality, optimize space utilization, reduce production costs, accelerate time to market, and ensure flexibility in product design. As consumer demands continue to evolve, it is essential for manufacturers in the grocery and household product industry to embrace SMT electronics to stay competitive in the market and meet the ever-changing needs of consumers. to Get more information at http://www.wootalyzer.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :