Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Exploring the Intricacies of Guitar Electronics Manufacturing

Category : | Sub Category : Posted on 2023-10-30 21:24:53

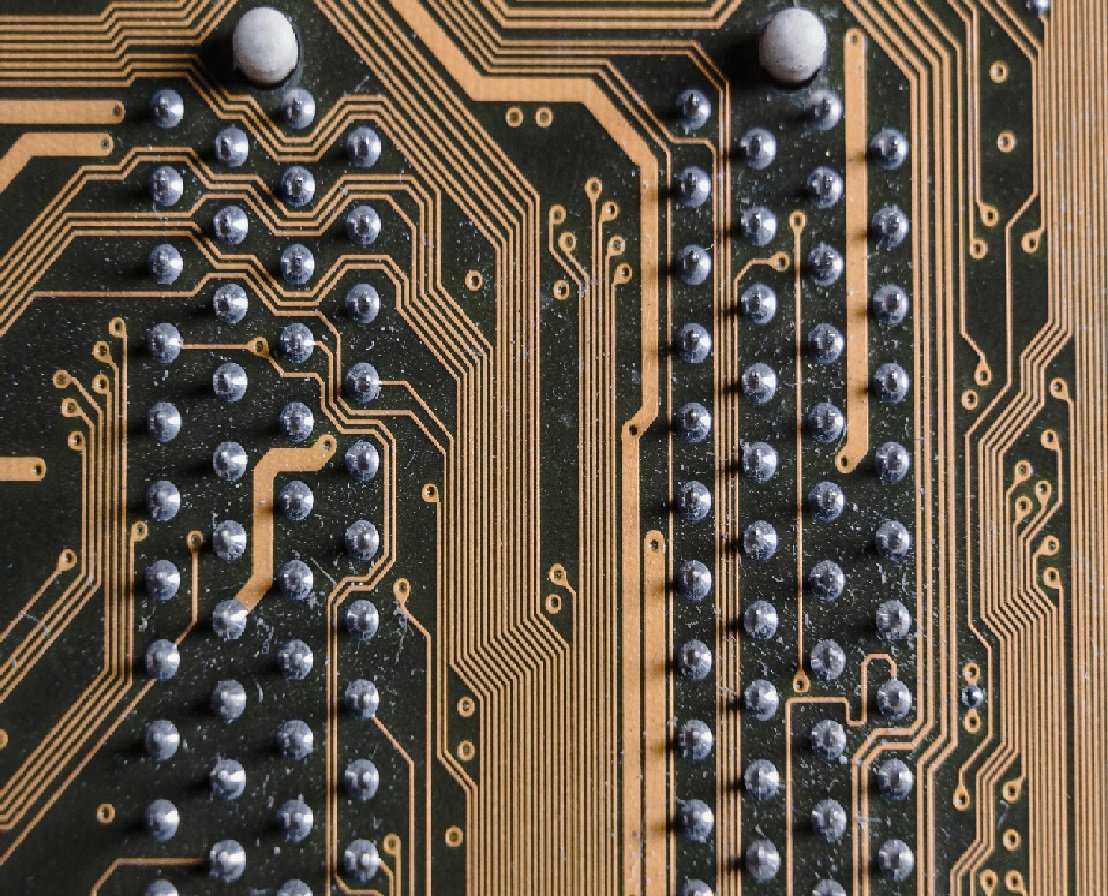

Introduction: Guitar electronics play a vital role in shaping the sound and functionality of electric guitars. Behind the scenes, guitar electronics manufacturing involves intricate processes and innovative technologies that contribute to the creation of high-quality instruments. This article aims to explore the key aspects of guitar electronics manufacturing, shedding light on the fascinating world of this essential component of the music industry. 1. The Evolution of Guitar Electronics: The concept of electronic guitars dates back to the 1930s when the first magnetic pickups were invented. These pickups converted the instrument's vibrations into electrical signals that could be amplified. Over the years, guitar electronics have undergone significant advancements, ranging from the introduction of solid-body designs to the incorporation of the latest digital signal processing technologies. 2. Components of Guitar Electronics: Guitar electronics consist of several essential components, each playing a specific role in the signal chain. These components include pickups, potentiometers (volume and tone controls), switches, capacitors, and output jacks. Each component is carefully selected, and their quality directly affects the tone, responsiveness, and overall performance of the guitar. 3. Manufacturing Techniques: Guitar electronics manufacturers employ various techniques to ensure superior quality and precision during the manufacturing process. Automated processes, such as surface mount technology (SMT), are commonly used to place and solder components onto printed circuit boards, ensuring consistency and reliability. Hand-wiring techniques are also utilized for high-end instruments, as they offer greater flexibility and customization possibilities. 4. Testing and Quality Control: To guarantee the highest standards, guitar electronics undergo meticulous testing and quality control procedures. Manufacturers employ advanced equipment to measure and analyze factors like signal purity, frequency response, noise levels, and electrical stability. Rigorous testing ensures that only electronics that meet stringent specifications make it into the final product. 5. Customization and Innovation: Guitar electronics manufacturing is not limited to mass production; it also offers ample opportunities for customization and innovation. Many manufacturers collaborate with renowned guitarists to develop signature pickups and electronics, tailored to specific playing styles and preferences. This flexibility allows musicians to express their unique voices and pushes the boundaries of what is sonically possible. 6. Environmental Considerations: Sustainable manufacturing practices are increasingly important in today's world. Forward-thinking guitar electronics manufacturers strive to reduce their carbon footprint by incorporating eco-friendly materials and adopting energy-efficient production processes. Recycling programs for used electronic components are also being implemented to minimize waste and promote a more sustainable approach within the industry. Conclusion: Guitar electronics manufacturing is a fascinating process that combines tradition, innovation, and precision. Manufacturers continuously strive to meet the demands of modern guitarists while pushing the boundaries of sound and technology. Whether it's the development of signature pickups or the integration of cutting-edge digital circuitry, the world of guitar electronics manufacturing plays an integral role in shaping the timbre and versatility of electric guitars, contributing to the rich tapestry of the music industry. To understand this better, read http://www.fguitars.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :