Home PCB Design software Electronics Prototyping Schematic Design Electronics Components

Exploring the Future of Guitar Electronics with Surface Mount Technology

Category : | Sub Category : Posted on 2023-10-30 21:24:53

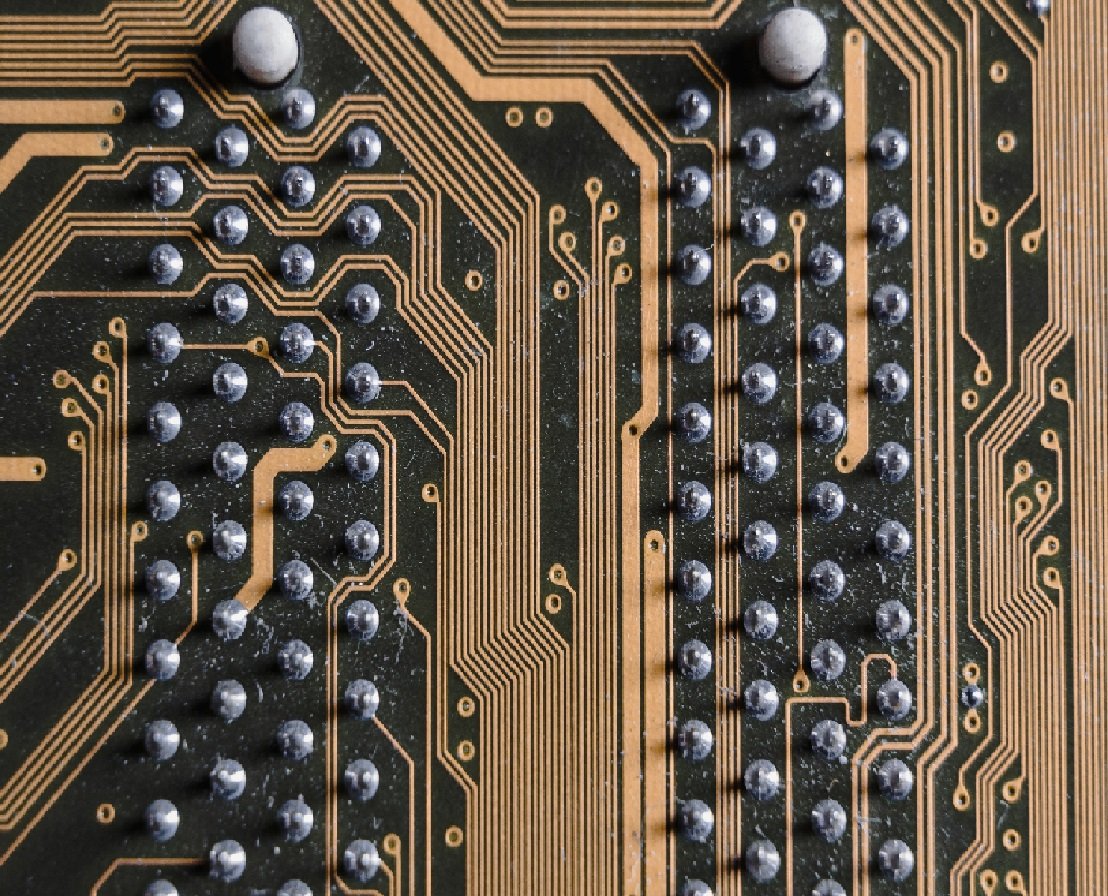

Introduction: In recent years, the guitar manufacturing industry has witnessed a significant shift towards embracing cutting-edge technologies to enhance the performance and functionality of electric guitars. One such technological advancement is Surface Mount Technology (SMT) in guitar electronics. SMT offers numerous benefits compared to traditional through-hole components, leading to improved tone, increased versatility, and enhanced reliability. In this blog post, we will delve into the world of guitar SMT electronics and explore the exciting possibilities it brings to the table. What is Surface Mount Technology (SMT)? Surface Mount Technology, commonly abbreviated as SMT, refers to a method of constructing electronic circuits where the components are mounted directly onto the surface of a printed circuit board (PCB). Unlike the traditional through-hole components, which require drilling holes in the PCB for the leads to pass through, SMT components are soldered onto the copper pads on the surface of the board. This approach grants several advantages, including smaller footprints, faster assembly, improved signal integrity, and increased component density. Benefits of SMT Electronics in Guitars: 1. Miniaturization: By utilizing SMT components, guitar manufacturers can create smaller and more compact electronic circuits, allowing for sleeker designs and improved ergonomics. This reduction in size and weight makes guitars more comfortable to play and easier to transport, without compromising on functionality. 2. Enhanced signal integrity: SMT components have shorter lead lengths, reducing parasitic capacitance and inductance that can interfere with signal integrity. This leads to improved signal clarity and a more defined and articulate tone. 3. Reliability and durability: SMT components are mechanically robust due to their secure solder connections and are less prone to damage from vibration or shock. This increased stability enhances the reliability and durability of guitar electronics, ensuring consistent performance over time. 4. Versatility: SMT technology allows for greater design flexibility, as components can be placed on both sides of the PCB. This enables the integration of a wide range of features, such as multi-function switches, high-quality digital effects, and MIDI compatibility. Guitarists can explore new tones and experiment with various sounds, taking their creativity to new heights. 5. Improved manufacturing efficiency: The automated assembly process of SMT electronics drastically reduces production time, ensuring faster turnaround times for guitar manufacturers. This efficiency can lead to cost savings for both manufacturers and consumers without compromising on the quality of the end product. The Future of Guitar Electronics: As the adoption of SMT in the guitar manufacturing industry continues to grow, we can expect even more advancements in guitar electronics. These innovations may include wireless connectivity options, integrated IoT (Internet of Things) capabilities, and advanced signal processing algorithms. Guitarists will have access to a whole new realm of sonic possibilities, allowing them to push the boundaries of creativity and expression. Conclusion: Surface Mount Technology is revolutionizing the world of guitar electronics, opening doors to endless possibilities. The miniaturization, enhanced signal integrity, improved reliability, and versatility offered by SMT components are transforming the way guitars are designed, manufactured, and played. As guitarists embrace this technology, they will undoubtedly experience a new level of musical innovation, allowing for unprecedented musical journeys. Whether you're a professional guitarist or an avid enthusiast, keep an eye on the evolving landscape of SMT electronics in the guitar industry it's an exciting time to be part of this revolution. Seeking answers? You might find them in http://www.fguitars.com

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :